Lithium ion battery cathode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in the field of lithium-ion battery positive electrode materials and its preparation, can solve problems such as poor conductivity, particle aggregation, lithium-nickel mixed discharge, etc., and achieve simple and easy preparation methods, excellent rate performance, and improved The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

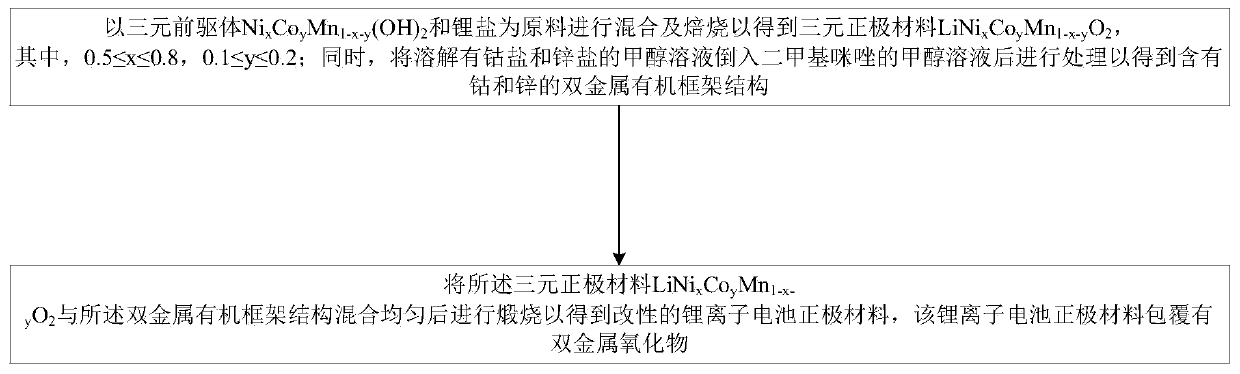

[0028] see figure 1 and figure 2 , the preparation method of lithium ion battery cathode material provided by the invention mainly comprises the following steps:

[0029] Step 1, with the ternary precursor Ni x co y mn 1-x-y (OH) 2 and lithium salt as raw materials for mixing and roasting to obtain the ternary cathode material LiNi x co y mn 1-x-y o 2 .

[0030] Specifically, the ternary precursor Ni x co y mn 1-x-y (OH) 2 It is mixed with lithium salt according to a predetermined molar ratio, then ball milled, and then calcined under a predetermined atmosphere to obtain the ternary cathode material LiNi x co y mn 1-x-y o 2 . Among them, 0.5≤x≤0.8, 0.1≤y≤0.2.

[0031] More specifically, the Ni x co y mn 1-x-y (OH) 2and lithium salt according to the molar ratio of 1:1.5~1:1 into the ball mill for 0.5h~2h. Sintering at ~900°C for 10h~20h to obtain the ternary cathode material LiNi x co y mn 1-x-y o 2 .

[0032] In this embodiment, the lithium salt ma...

Embodiment 1

[0041] The preparation method of the lithium-ion battery cathode material provided by Example 1 of the present invention mainly includes the following steps:

[0042] S1, the Ni 6 co 2 mn 2 (OH) 2 Add lithium salt and lithium salt into the ball mill at a molar ratio of 1:1, the ball milling time is 1h, and the ball mill speed is 300r / min. After the ball milling is completed, the obtained product is put into a muffle furnace and sintered at 900°C for 10h to obtain a ternary positive electrode Material;

[0043] S2, configure the concentration of zinc nitrate and cobalt nitrate to be 50ml of methanol solution of 0.05mol / L and 0.01mol / L respectively, and pour 50ml of methanol solution of dimethylimidazole with a concentration of 0.2mol / L to obtain the mixed After standing for 24 hours, the bimetallic ZIF (BMZIF) containing metal cobalt and zinc was obtained by centrifugation, washing and drying.

[0044] In S3, the obtained ternary cathode material and the obtained BMZIF pow...

Embodiment 2

[0046] The preparation method of the lithium-ion battery positive electrode material provided by Example 2 of the present invention mainly includes the following steps:

[0047] S1, the Ni 6 co 2 mn 2 (OH) 2 Add lithium salt and lithium salt into the ball mill at a molar ratio of 1:1.3, the ball milling time is 1h, the ball mill speed is 300r / min, after the ball milling is completed, the obtained product is put into a muffle furnace and sintered at 800°C for 15h to obtain a ternary positive electrode Material;

[0048] S2, configure the concentration of zinc nitrate and cobalt nitrate to be 25ml of methanol solution of 0.04mol / L and 0.04mol / L respectively, and pour 50ml of methanol solution of dimethylimidazole with a concentration of 0.2mol / L to obtain the mixed After standing for 24 hours, the bimetallic ZIF (BMZIF) containing metal cobalt and zinc was obtained by centrifugation, washing and drying.

[0049] In S3, the obtained ternary cathode material and the obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com