Method for hydrothermal growth of hydrated di-strontium-11-borate single crystal

A growth method, boric acid technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem of no artificial synthesis of hydrated distrontium undecaborate crystals, no reports of research and application of crystal growth methods, etc. Problems, to achieve the effect of not easy dehydration, easy operating conditions, and the realization of operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

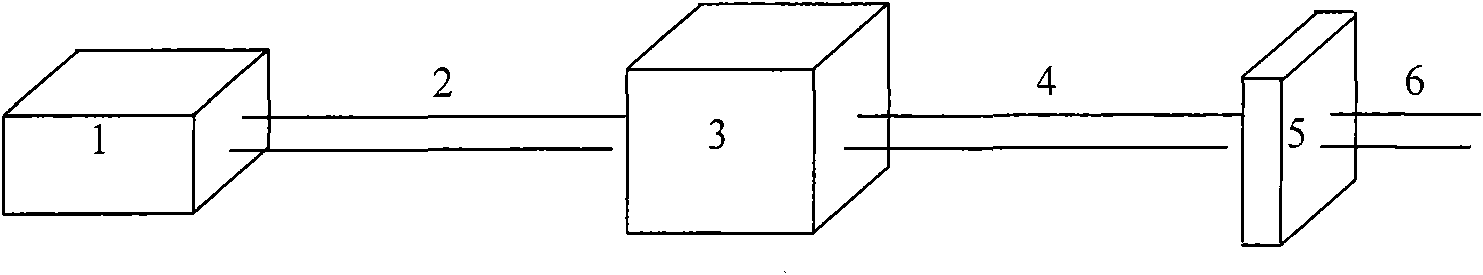

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, strontium salt (strontium carbonate) and boron-containing compound (boric acid) are selected as raw materials, and water is used as a solvent to form a hydrated distrontium undecaborate single crystal through dissolution, hydration and crystallization of raw materials in a hydrothermal medium; Proceed as follows:

[0044] Weigh 1.200 grams of strontium carbonate and 3.016 grams of boric acid (Sr, B atomic molar ratio 1: 6), mix and pack into an autoclave with a volume of Φ40mm×90mm, and add a concentration of 1.0mol / L HCl solution;

[0045] After sealing, put the autoclave into a constant temperature drying oven, raise the temperature to 210°C, and then maintain a constant temperature of 210°C±1°C for five days. Close the constant temperature drying oven, and after the furnace temperature drops to room temperature, take out the autoclave from the constant temperature drying oven, open the autoclave, wash, filter, and dry to obtain a colorless and t...

Embodiment 2

[0049] Weigh 2.000 grams of strontium carbonate and 2.358 grams of boron oxide (Sr, B atomic molar ratio 1:5), mix and put into an autoclave with a volume of Φ40mm×90mm, and add a concentration of 1.5 to a filling degree of 65% of the autoclave volume. mol / L of H 3 BO 3 solution; after sealing, put the autoclave into a constant temperature drying oven, raise the temperature to 230°C, and then maintain a constant temperature of 230°C±1°C for seven days; close the constant temperature drying oven, and take out the autoclave from the constant temperature drying oven after the furnace temperature drops to room temperature , open the autoclave, wash, filter, and dry to obtain a colorless and transparent single crystal with a size of 3.1mm×1.1mm×0.9mm.

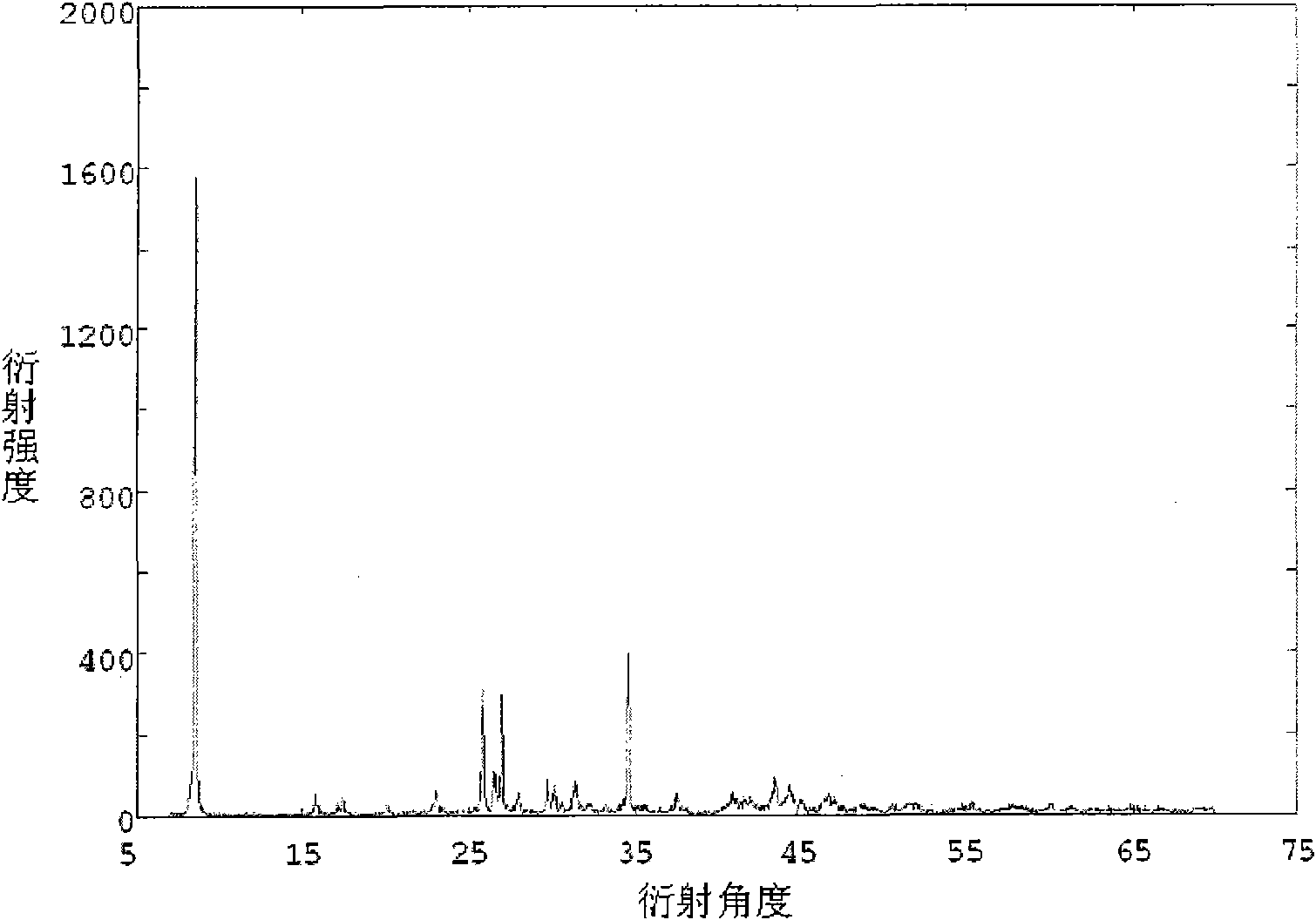

[0050] The X-ray diffraction pattern test of the obtained crystal is consistent with the powder diffraction file database card (JCPDS card) of the natural hydrated distrontium undecaborate single crystal, and it is proved to be the...

Embodiment 3

[0052] Weigh 3.000 grams of strontium chloride and 2.635 grams of boron oxide (Sr, B atomic molar ratio 1:4), mix them, put them into an autoclave with a volume of Φ40mm×90mm, and add them according to the filling degree of 50% of the autoclave volume. Ionized water; after sealing, put the autoclave into a constant temperature drying oven, raise the temperature to 270°C, and then maintain a constant temperature of 270°C±1°C for ten days. Close the constant temperature drying oven, take out the autoclave from the constant temperature drying oven after the furnace temperature drops to room temperature, open the autoclave, wash, filter, and dry to obtain a colorless and transparent single crystal with a size of 2.7mm×1.2mm×0.7mm.

[0053] The X-ray diffraction pattern of the obtained crystal is consistent with the powder diffraction file database card (JCPDS card) of the natural hydrated distrontium undecaborate single crystal, which proves to be the hydrated distrontium undecabor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com