Injection moulding-based high-efficiency heavy-duty transmission nut material, method and device

A transmission nut and nut technology, applied in the coating and other directions, can solve the problems of complex lining production process, hindering the application in heavy-duty fields, bearing capacity limitation, etc., and achieve the effect of improving equipment efficiency, ingenious design, and effective lubricating oil passages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

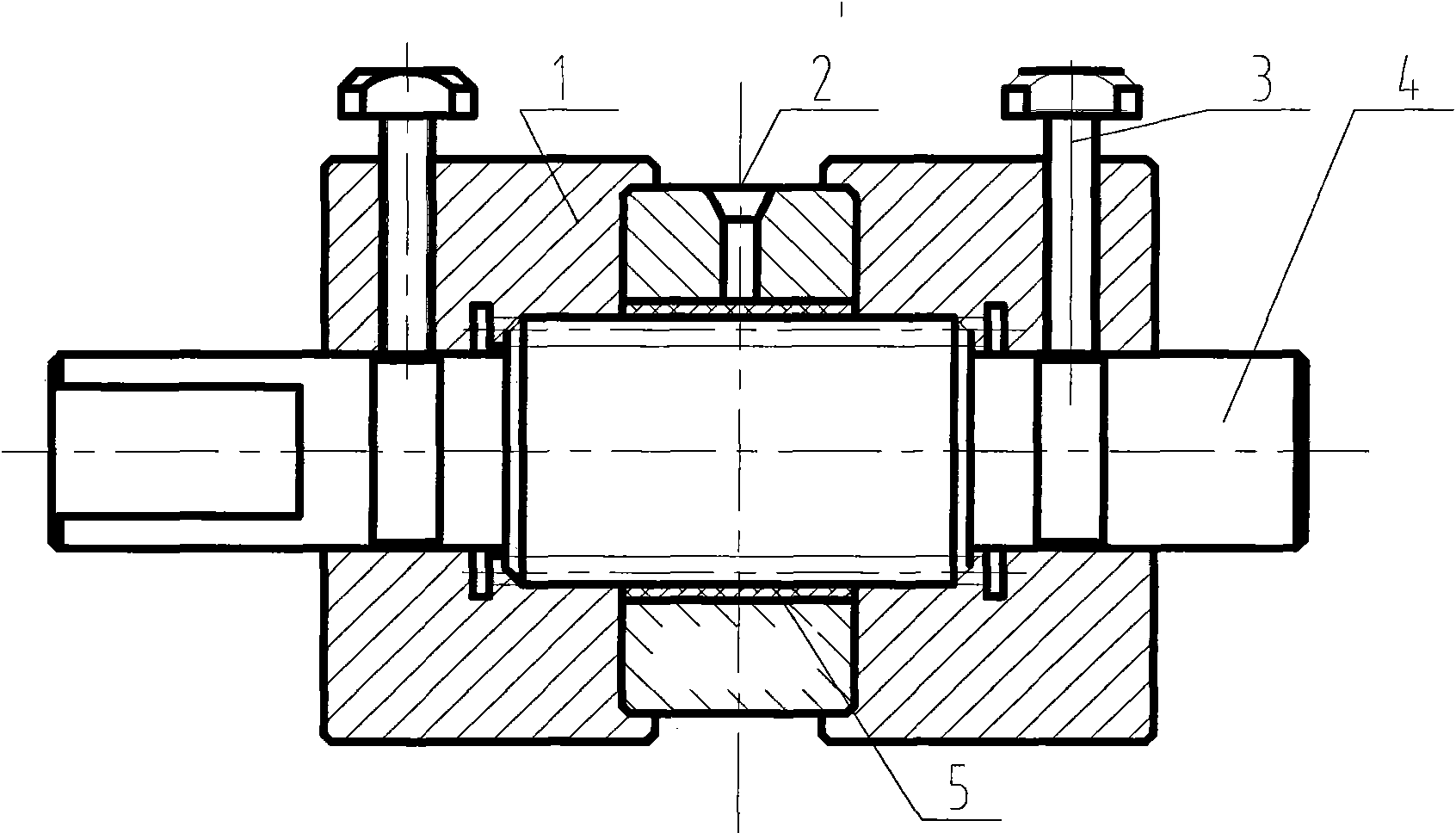

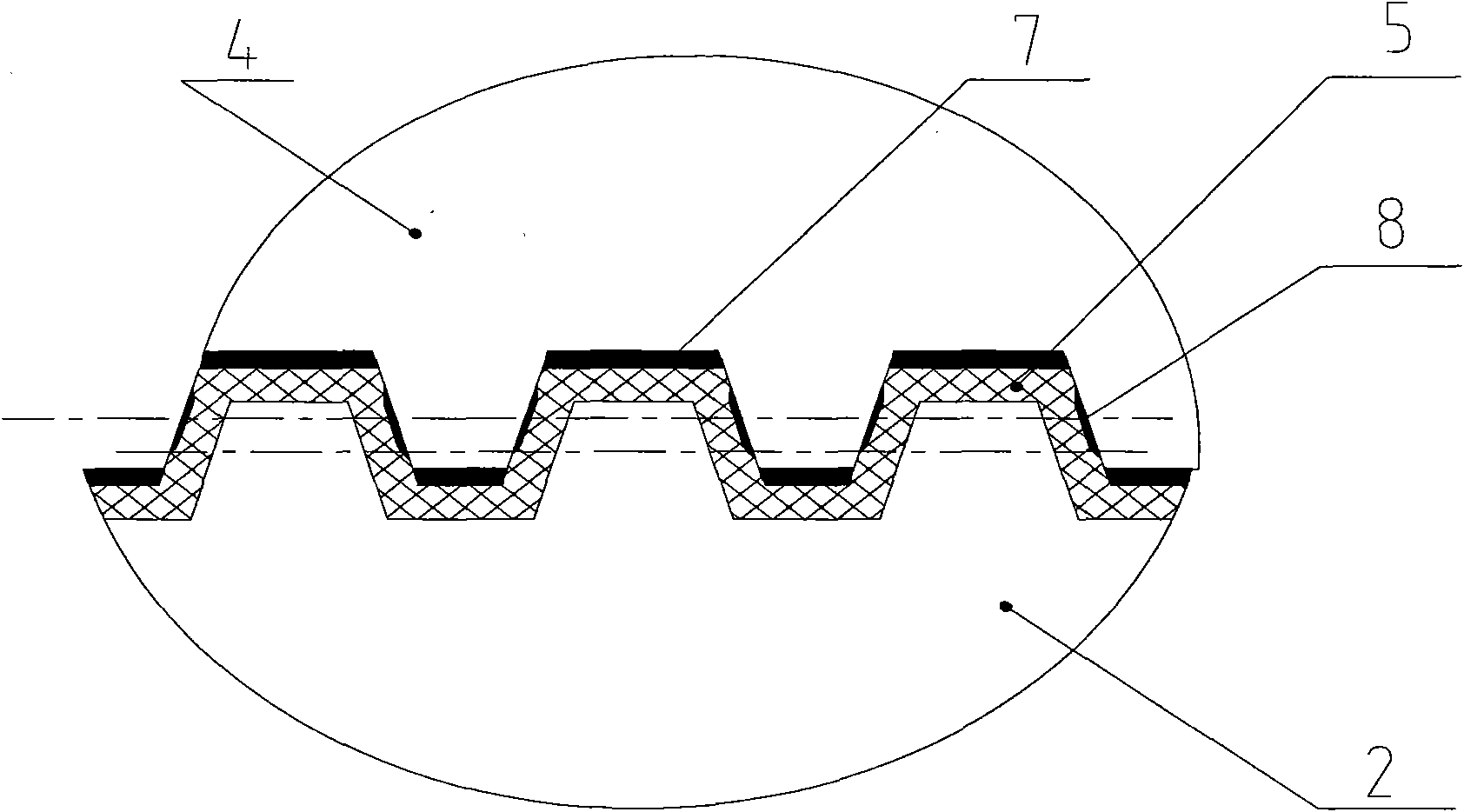

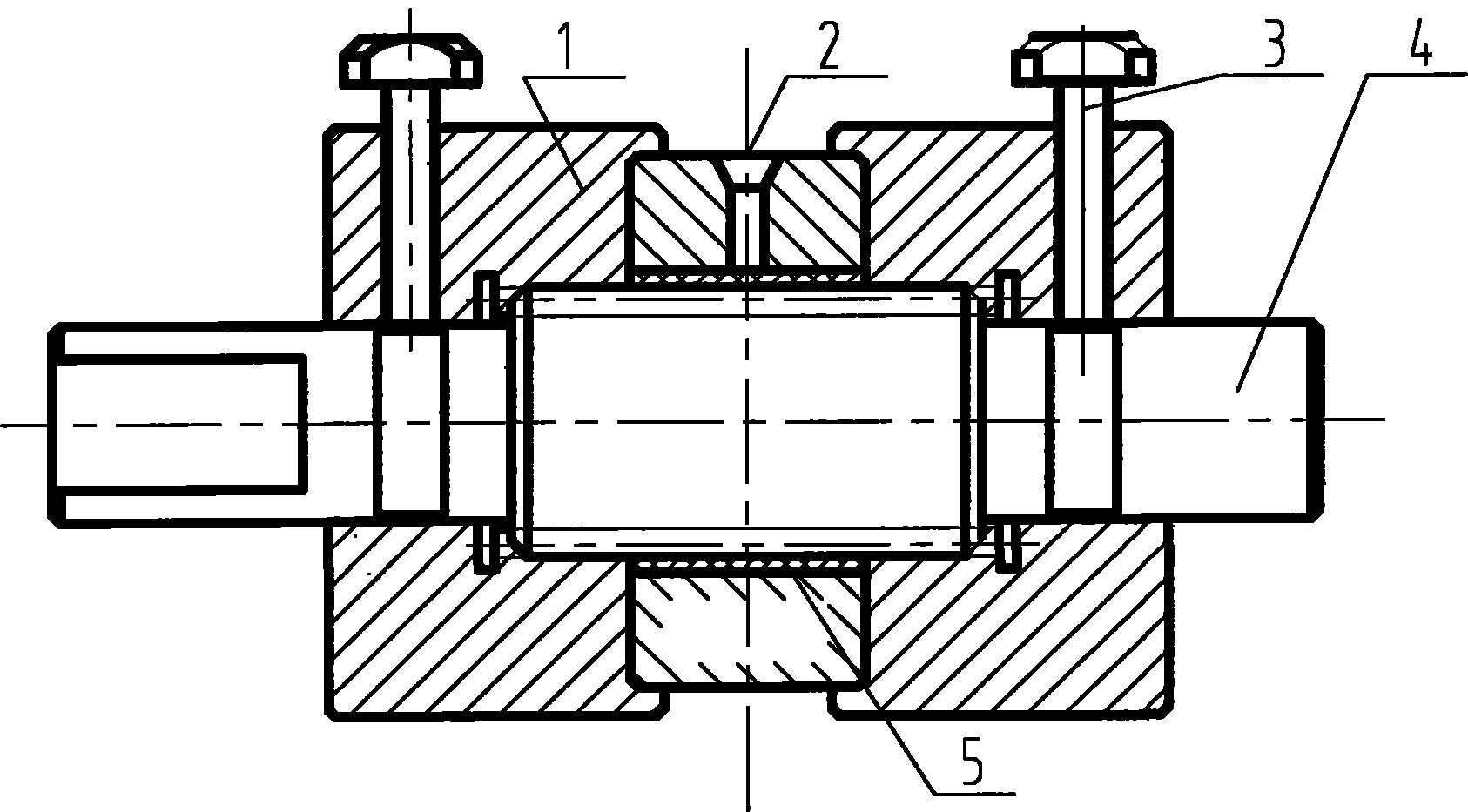

[0025] The structural representation of the self-lubricating transmission nut forming device of the present invention is as follows figure 1 As shown, it includes a process screw 4, a base nut 2, a positioning member 1, and a tightening member 3, wherein the process screw 4 is screwed into the transmission nut 2, and the internal thread of the base nut 2 is connected to the surface of the external thread of the process screw 4. A gap is reserved between which self-lubricating material can be injected to form a self-lubricating lining 5 , and the two ends of the base nut 2 are provided with a positioning member 1 , and the positioning member 1 is locked by a tightening member 3 .

[0026] A gap of 1 mm to 2 mm is reserved between the internal thread of the base nut 2 and the surface of the external thread of the process screw 4 . In this embodiment, a gap of 1 mm is reserved between the internal thread of the base nut 2 and the surface of the external thread of the process scre...

Embodiment 2

[0038] The method and device of this embodiment are the same as those of Embodiment 1, except that the proportioning of the lining material is different. The proportioning of the lining material in this embodiment is as follows:

[0039] Epoxy resin 40 Toughening agent, dispersant 6 Talcum powder 400 mesh 8

[0040] Graphite 2 Molybdenum Disulfide 15 Carbon Fiber 10 Curing Agent 19.

Embodiment 3

[0042] The method and device of this embodiment are the same as those of Embodiment 1, except that the proportioning of the lining material is different. The proportioning of the lining material in this embodiment is as follows:

[0043] Epoxy resin 45 toughening agent, dispersant 8 talcum powder 400 mesh 5

[0044] Graphite 3 Molybdenum Disulfide 10 Carbon Fiber 14 Curing Agent 15.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com