Multilayer film for low load working condition of micro electro mechanical system and preparation method thereof

A micro-electromechanical system and multi-layer thin film technology, which is applied to the components of TV systems, the process for producing decorative surface effects, generators/motors, etc., can solve the problem of damage to silicon materials, insufficient pressure resistance of self-assembled films, Device failure and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

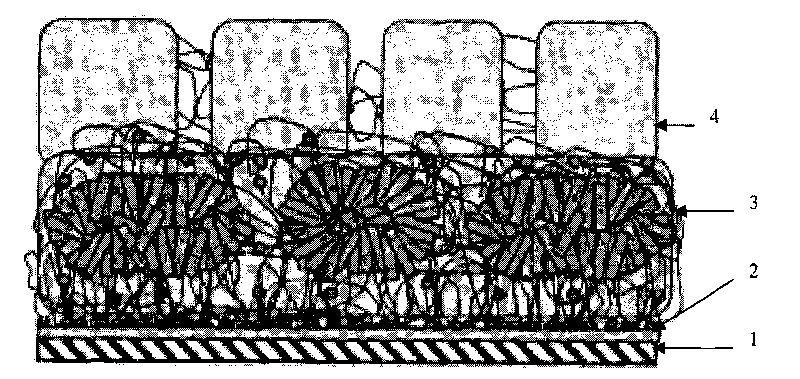

Embodiment Construction

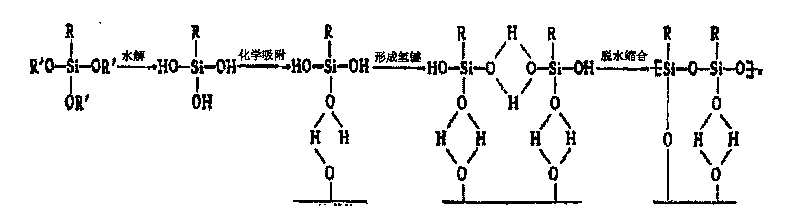

[0029] CHCl 3 , ethanol and acetone (analytically pure) were ultrasonically cleaned in sequence to remove organic impurities, and then put them into HCl and H 2 o 2 Soak in the aqueous solution for 5-10 minutes, remove the surface oxide layer, and then put in water, ammonia water and H at a volume ratio of 6:1:1 2 o 2 Carry out hydroxylation reaction, the concentration of ammonia water is 30%, the reaction mechanism is as follows figure 2 After the reaction, rinse with deionized water and dry in a fume hood after cleaning.

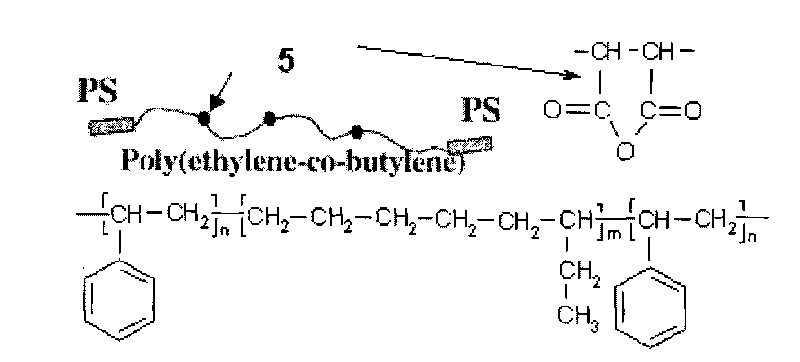

[0030] Dissolve the commercially available silane coupling agent KH-560 containing ethoxy and amino groups in toluene to form a 1% solution by mass, then put the cleaned silicon sample into the solution and soak for 30 minutes, Make KH-560 (molecular formula NH 2 (CH 2 ) 3 Si(OC 2 h 5 ) 3 ) in the ethoxy group and the silicon surface to generate Si-O-Si grafts, so that the silane coupling agent is connected to the silicon substrate 4 through che...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com