High-hardness wear-resistance netty structured double-metal titanium base composite material and preparation method thereof

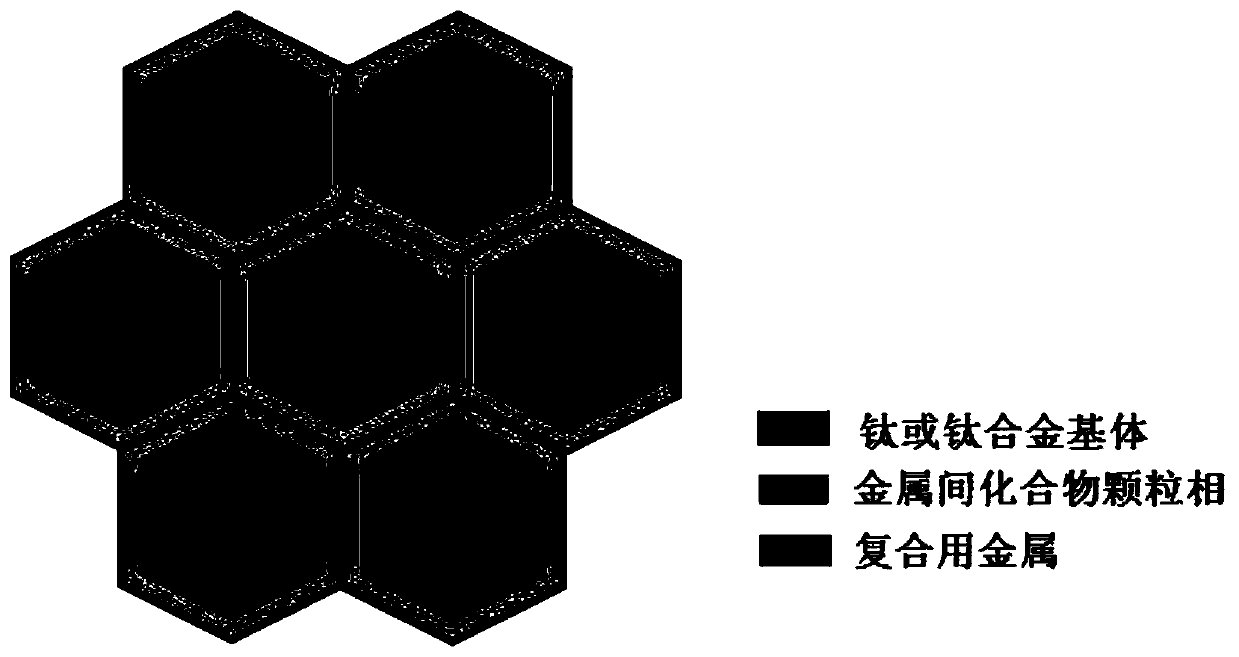

A technology of titanium-based composite materials and network structure, which is applied in the field of high-hardness and wear-resistant network-structured bimetallic titanium-based composite materials and its preparation, can solve the problems affecting the service life and scope of use of titanium-based composite materials, and plastic deformation resistance. The shear ability and surface oxidation resistance are poor, and the bonding ability is different, so as to inhibit the reaction of in-situ self-generated titanium carbide, improve the composite compactness and bonding strength, and increase the hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

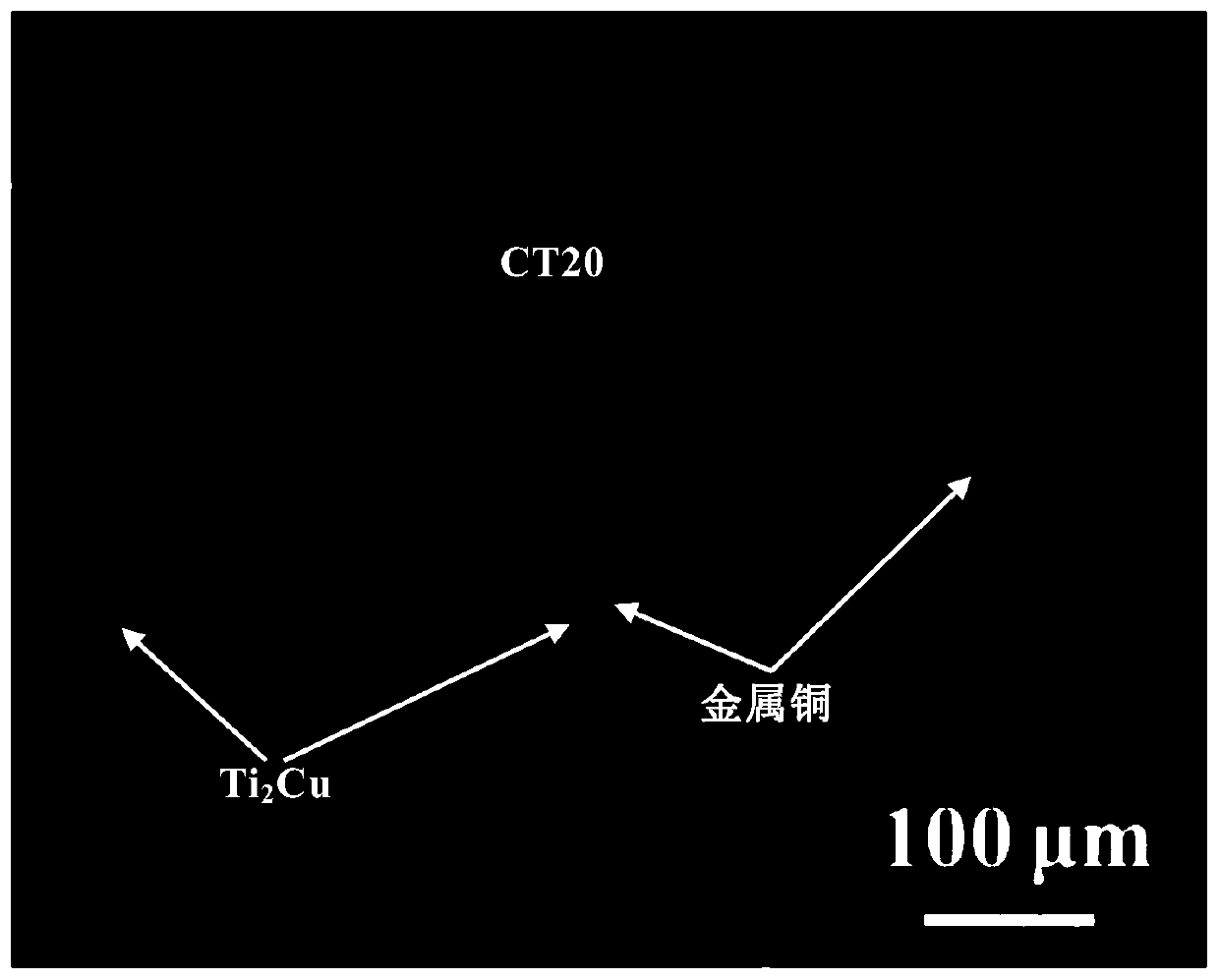

[0029] In this example, the high-hardness and wear-resistant reticulated bimetallic titanium-based composite material uses CT20 titanium alloy as the matrix, and the intermetallic compound Ti produced by copper and CT20 titanium alloy in situ. 2 The Cu particle phase and copper are uniformly and continuously distributed on the surface of the CT20 titanium alloy substrate in turn in a ring shape, forming a network structure Ti-Cu bimetallic titanium matrix composite material; the average equivalent diameter of the mesh in the network structure is 150 μm.

[0030] The preparation method of the high-hardness and wear-resistant reticulated bimetallic titanium-based composite material in this embodiment includes the following steps:

[0031] Step 1. Selection of powder: Select 100g of spherical CT20 titanium alloy powder with a particle size of 80 mesh to 120 mesh, a Mohs hardness of 6.0, and a sphericity of 0.8 as the matrix powder, and select 100g of a particle size of 120 mesh t...

Embodiment 2

[0041] In this example, the high-hardness and wear-resistant reticulated bimetallic titanium-based composite material uses CT20 titanium alloy as the matrix, and the intermetallic compound Ti produced by copper and CT20 titanium alloy in situ. 2 The Cu particle phase and copper are uniformly and continuously distributed on the surface of the CT20 titanium alloy substrate in turn in a ring shape, forming a network structure Ti-Cu bimetallic titanium matrix composite material; the average equivalent diameter of the mesh in the network structure is 80 μm.

[0042] The preparation method of the high-hardness and wear-resistant reticulated bimetallic titanium-based composite material in this embodiment includes the following steps:

[0043] Step 1. Selection of powder: select 120 g of spherical CT20 titanium alloy powder with a particle size of 150 mesh to 200 mesh, a Mohs hardness of 6.0, and a sphericity of 0.9 as the matrix powder, and select 80 g of a particle size of 150 mesh ...

Embodiment 3

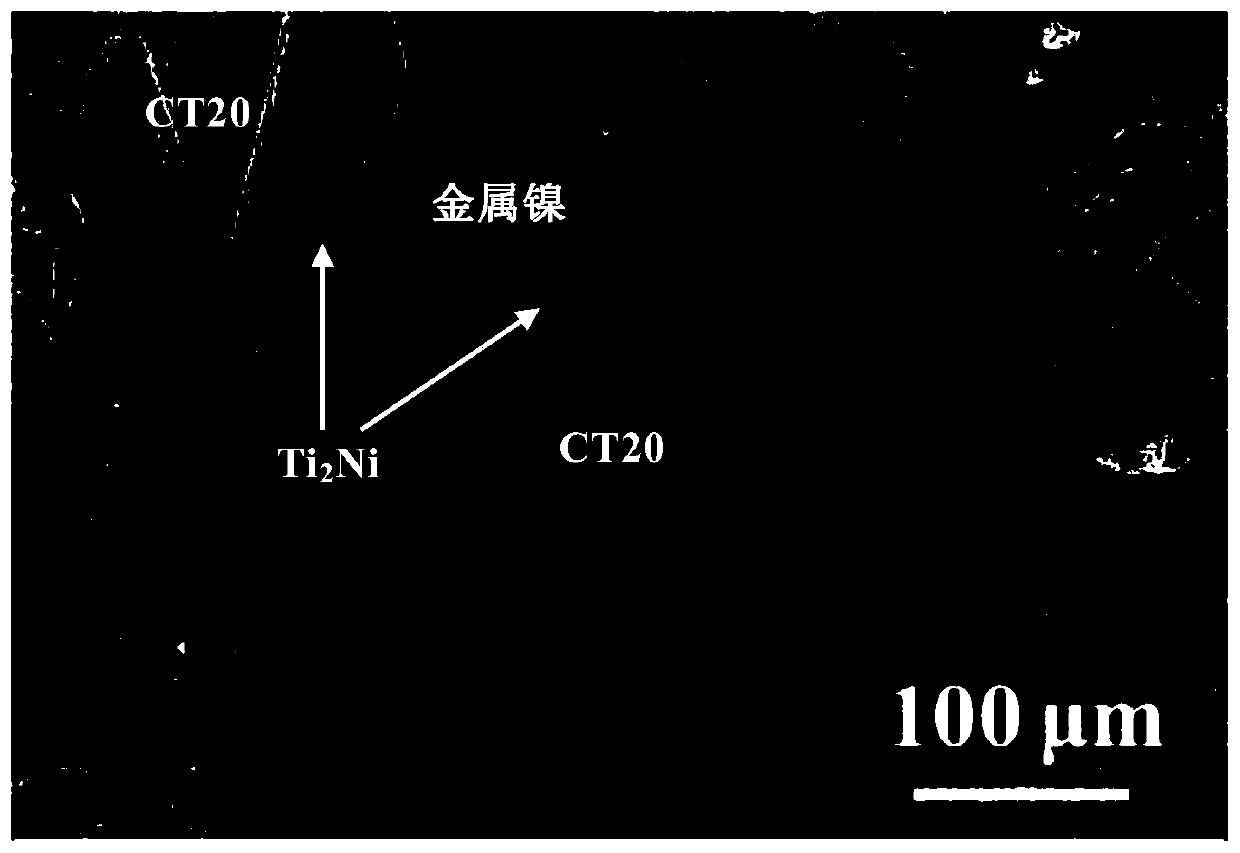

[0050] In this embodiment, the high-hardness and wear-resistant reticulated bimetallic titanium-based composite material uses CT20 titanium alloy as the matrix, and the intermetallic compound Ti formed by nickel and CT20 titanium alloy in situ. 2 The Ni particle phase and nickel are uniformly and continuously distributed on the surface of the CT20 titanium alloy substrate in turn in a ring shape, forming a network structure Ti-Ni bimetallic titanium matrix composite material; the average equivalent diameter of the grid in the network structure is 120 μm.

[0051] The preparation method of the high-hardness and wear-resistant reticulated bimetallic titanium-based composite material in this embodiment includes the following steps:

[0052] Step 1. Selection of powder: select 100 g of spherical CT20 titanium alloy powder with a particle size of 100 mesh to 150 mesh, a Mohs hardness of 6.2, and a sphericity of 1.0 as the matrix powder, and select 50 g of a particle size of 200 mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com