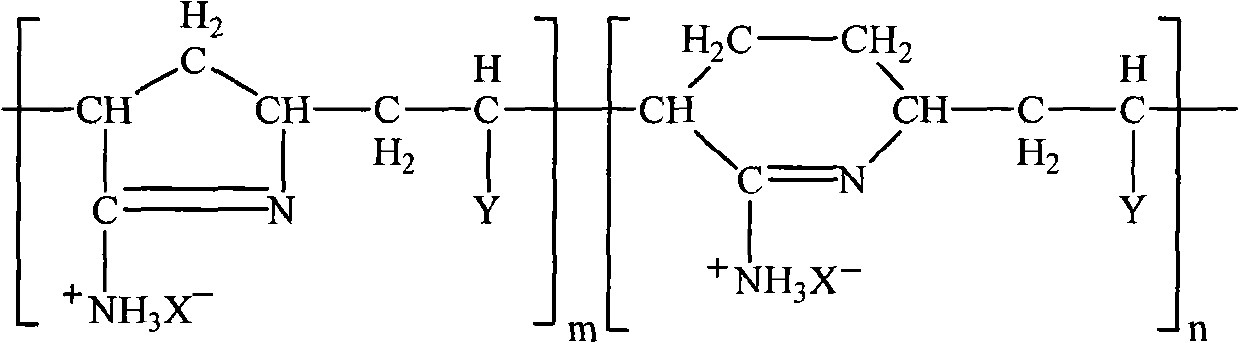

Ring amidino-polymer flocculant and preparation method thereof

A polymer flocculant, amidine-based technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of high molecular weight, short flocculation and sedimentation time, and small application range of acrylamide-modified flocculants, and achieve high-efficiency flocculation. , the effect of high molecular weight and high intrinsic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Room temperature, N 2 Under the atmosphere, mix 10g of acrylamide and 10mL of acrylonitrile, then add 100mL of deionized water, stir well, then add 5mL of 0.5% aqueous solution of azobisisobutylamidine hydrochloride dropwise at 65°C for 20min. After completion of the reaction, the reaction was continued for 8 hours. After the reaction, the reaction solution was poured into acetone with 3 times the volume of the reaction solution, filtered, and vacuum-dried at 50° C. to obtain a white acrylamide-acrylonitrile polymer;

[0019] At -10°C, mix 10mL of 10% acrylamide-acrylonitrile polymer aqueous solution with 30mL of sodium hypochlorite aqueous solution with an available chlorine content of 6%, then add 100mL of 10M sodium hydroxide aqueous solution to react for 1 hour, and then continue to react at 0°C for 10 hours After the reaction, the reaction solution was poured into acetone with 3 times the volume of the reaction solution, filtered to obtain a light yellow modified p...

example 2

[0022] Room temperature, N 2 Under the atmosphere, mix 10g of acrylamide and 10mL of acrylonitrile, then add 100mL of deionized water, after stirring evenly, add 3mL of 0.5% potassium persulfate and 3mL of 0.5% sodium bisulfite mixed aqueous solution dropwise at 65°C , 20min. After dripping, continue the reaction for 8h. After the reaction, pour the reaction solution into acetone with 3 times the volume of the reaction solution, filter, and vacuum dry at 50°C to obtain a white acrylamide-acrylonitrile polymer;

[0023] At -10°C, mix 10mL of 10% acrylamide-acrylonitrile polymer aqueous solution with 30mL of sodium hypochlorite aqueous solution with an available chlorine content of 6%, then add 100mL of 10M sodium hydroxide aqueous solution to react for 1 hour, and then continue to react at 0°C for 10 hours After the reaction, the reaction solution was poured into acetone with 3 times the volume of the reaction solution, filtered to obtain a light yellow modified polymer interme...

example 3

[0026] Room temperature, N 2 Under atmosphere, mix 8g of acrylamide, 2g of N-vinylformamide and 10mL of acrylonitrile, then add 100mL of deionized water, stir well, then add 5mL of 0.5% azobisisobutylamidine salt dropwise at 65°C Aqueous acid salt solution, 20min. After dripping, continue to react for 8h. After the reaction, pour the reaction solution into acetone with 3 times the volume of the reaction solution, filter, and vacuum dry at 50°C to obtain a white acrylamide-acrylonitrile polymer;

[0027] At -10°C, mix 10mL of 10% acrylamide-acrylonitrile polymer aqueous solution with 30mL of sodium hypobromite aqueous solution with an effective bromine content of 6%, and then add 100mL of 10M sodium hydroxide aqueous solution to react for 1 hour, then at 0°C Continue the reaction for 10 hours. After the reaction, pour the reaction solution into acetone with 3 times the volume of the reaction solution, filter to obtain a light yellow modified polymer intermediate, add water to d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com