Sulfamic acid amphoteric surfactant and synthesis method thereof

A surfactant and sulfamic acid technology, applied in the preparation of sulfonate, chemical instruments and methods, organic chemistry, etc., can solve the problems of no immediate treatment, influence on product yield, intensified reverse reaction, etc., and achieve low product cost , The solvent is cheap and easy to get, and the effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

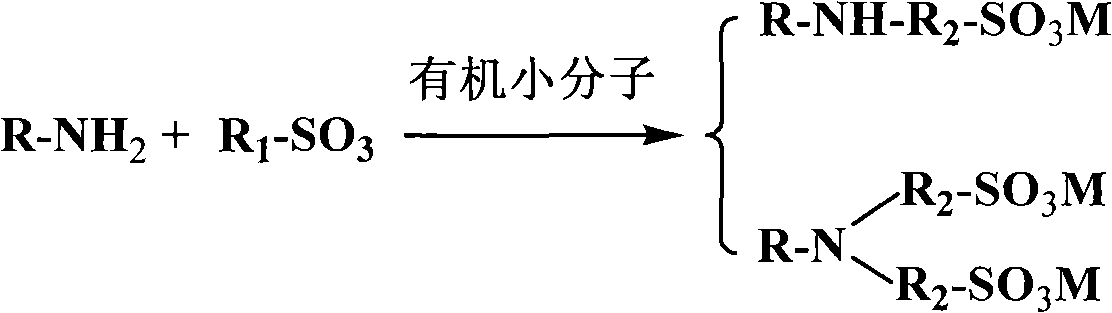

Method used

Image

Examples

Embodiment 1

[0051] The preparation of the sulfamic acid type amphoteric surfactant such as structure shown in formula (1):

[0052]

[0053] Add 25mL of ethylenediamine into a 250mL three-neck flask, maintain the system temperature at 90°C with a water filter, slowly add 12mL of 1-bromododecane dropwise under stirring, and react for 1 hour after the drop is completed, adjust with 40% NaOH solution The pH value of the reaction liquid system is in the range of 9-11. After continuing to stir and react for 5 hours, the excess ethylenediamine is evaporated and cooled to obtain N-dodecylethylenediamine solid (intermediate A).

[0054] Take 4.6g of the intermediate A obtained above and put it into a three-necked flask, then add 28mL of water, stir and raise the temperature to 95°C, after the reaction solution is evenly stirred, slowly add 2-hydroxy-3-chloropropane with a mass percentage of 20% Sodium sulfonate solution, after adding dropwise and stirring at constant temperature for 1 hour, ad...

Embodiment 2

[0056] The preparation of the sulfamic acid type amphoteric surfactant such as structure shown in formula (2):

[0057]

[0058] Add 100mL of ethylenediamine into a 250mL three-necked flask, filter with water to maintain the system at 95°C, slowly add 60mL of 1-bromohexadecane dropwise under stirring, and after stirring for 1 hour, use 35% NaOH solution to adjust the pH of the system at In the range of 9-11, continue to stir for 4 hours, distill off excess ethylenediamine, and wash with water to obtain a white paste solid—N-hexadecylethylenediamine (intermediate B).

[0059] Take 28.54g of intermediate B and dissolve it in 70mL of ethanol, heat to 85°C, slowly add 19.95g of 2-hydroxy-3-chloropropanesulfonate sodium 20% solution (prepared with 70% alcohol aqueous solution) dropwise under stirring , after dropping, the temperature was raised to 90° C., and the temperature was kept constant for 1 hour, 12 mL of 35% NaOH solution was added, and the reaction was continued for 5 ...

Embodiment 3

[0061] Measure the surface tension of conventional tensio-active agent, embodiment 1, the tensio-active agent of example 2 and other several surfactants synthesized with this method with JK99B type full-automatic tensiometer, obtain their critical micelle concentration (CMC) and The surface tension at the CMC (γ CMC ) data are shown in Table 1.

[0062] Several sulfamic acid type amphoteric surfactants of table 1 synthesis and the CMC and

[0063] Surfactant

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com