Organic acid method for preparing ultrafine partial stable zirconia

A stable zirconia, ultra-fine technology, applied in zirconia, nanostructure manufacturing, nanotechnology and other directions, can solve the problems of low flexural strength, low sintering yield and high sintering temperature, and achieve powder performance improvement, The effect of uniform distribution and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

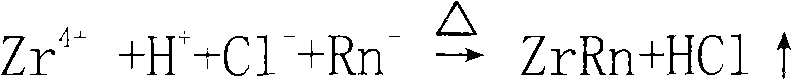

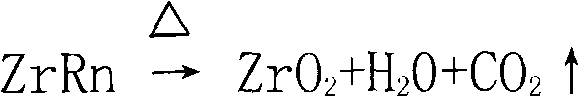

Method used

Image

Examples

Embodiment 1

[0015] (1) Weigh tartaric acid (malic acid is prepared in the same way, if not repeated), zirconium oxychloride (ZrOCl 2 ·8H 2 O), pinpinga, cetyl sulfonic acid, yttrium nitrate. Wherein the molar ratio of zirconium oxychloride to yttrium nitrate is 1:0.03, zirconium oxychloride (ZrOCl 2 ·8H 2 The molar ratio of O) to tartaric acid is 1:3, zirconium oxychloride (ZrOCl 2 ·8H 2 O), the molar ratio of tensio-active agent is 1: 0.004, and the ratio of pinpinga and hexadecanoic acid is 1: 3.

[0016] (2) Prepare a 1mol / L tartaric acid solution for later use, and prepare a 10% solution of Pingpinga and cetylbenzenesulfonic acid for later use.

[0017] (3) Stir the tartaric acid solution in a reaction kettle (300-500r / min) and heat it to 65°C, add zirconium oxychloride, wait until the zirconium oxychloride is completely dissolved, and control the pH=1-2. Heat slowly to 95°C and keep warm. When the pH value is 4-5, add the already prepared Pingpinga and cetylbenzenesulfonic aci...

Embodiment 2

[0019] (1) As in Example 1, the ratio of Pingpingjia to hexadecanoic acid is 2:2.

[0020] (2) Prepare 1.5 mol / L tartaric acid solution for later use, and prepare 10% solution of Pingpinga and cetylbenzenesulfonic acid for later use.

[0021] (3) Stir the tartaric acid solution in a reaction kettle (300-500r / min) and heat it to 65°C, add zirconium oxychloride, wait until the zirconium oxychloride is completely dissolved, and control the pH=1-2. Heat slowly to 95°C and keep warm. When the pH=4-5, add the prepared Pingpinga and cetylbenzenesulfonic acid solution, continue to heat and evaporate the water, and calcined at 750°C-900°C for 10 hours, the particle size of the powder is 50 -65nm.

Embodiment 3

[0023] (1) As in Example 1.

[0024] (2) Prepare a 1mol / L tartaric acid solution for later use, and prepare a 10% solution of Pingpinga and cetylbenzenesulfonic acid for later use.

[0025] (3) Stir the mixed acid solution in a reaction kettle (300-500r / min) and heat it to 65°C, add zirconium oxychloride, wait until the zirconium oxychloride is completely dissolved, and control the pH=1-2. Heat slowly to 95°C and keep warm. When the pH is 4-5, add the prepared Pingpinga and cetylbenzenesulfonic acid solution, continue to heat and evaporate the water, and calcinate at 750°C-900°C for 6 hours, the particle size of the powder is 30-48nm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com