Coal tar pitch for high-grade roads

A kind of coal tar pitch, high-grade technology, applied in the field of coal tar pitch for grade roads, can solve problems such as easy drumming, flow, complex structure construction troubles, constraints, etc., to reduce environmental pollution, increase use value, and relieve supply tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh the following raw materials in parts by weight:

[0025] 90 parts of coal tar pitch

[0026] 4 copies of SBS

[0027] 3 parts plastic waste

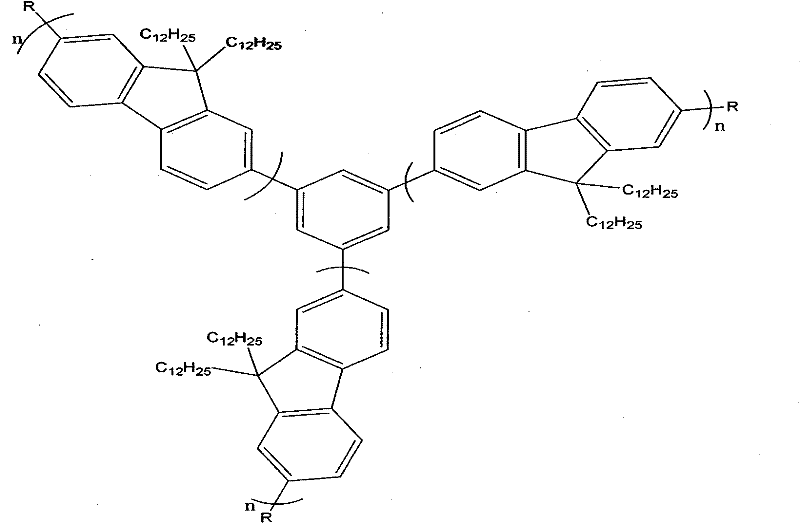

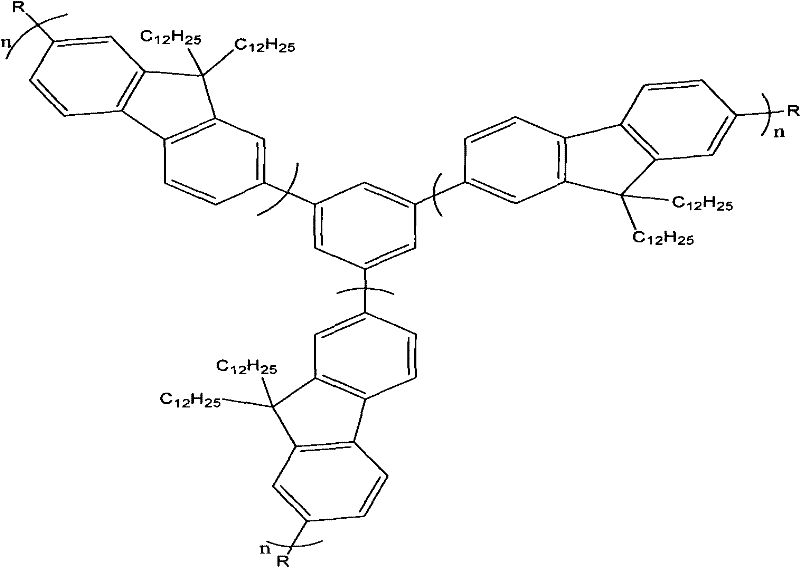

[0028] Star-shaped fluorene polymer 2 parts

[0029] 4 parts polyphosphoric acid

[0030] Add modifier styrene block copolymer SBS, waste plastics, star-shaped fluorene polymer and co-solvent polyphosphoric acid to base coal tar pitch, mix and melt at 170-200°C, and then grind and shear by colloid mill Cut for 30-40 minutes and evenly disperse in asphalt cement to obtain the coal tar pitch for high-grade roads of the present invention.

Embodiment 2

[0032] Weigh the following raw materials in parts by weight:

[0033] 85 parts of coal tar pitch

[0034] 2 copies of SBS

[0035] 2 servings of waste plastic

[0036] Star-shaped fluorene polymer 2 parts

[0037] 4 parts polyphosphoric acid

[0038] Add modifier styrene block copolymer SBS, waste plastics, star-shaped fluorene polymer and co-solvent polyphosphoric acid to base coal tar pitch, mix and melt at 170-200°C, and then grind and shear by colloid mill Cut for 30-40 minutes and evenly disperse in asphalt cement to obtain the coal tar pitch for high-grade roads of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com