Fluorine-containing imine matrix resin used for advanced composite material and preparation method thereof

A technology of fluorine-containing imine matrix and advanced composite materials, which is applied in the field of fluorine-containing imide matrix resin and its preparation for advanced composite materials, and can solve the problems that have not yet been published in literature or patent reports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

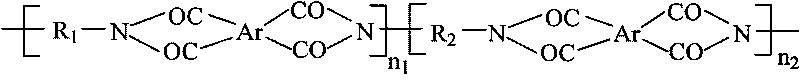

Image

Examples

Embodiment 1

[0049] 54.6 g (0.1 mole) of 2,2-bis[4-(4-amino-2-trifluoromethylphenoxy) phenyl] propane fluorine-containing diamine monomer, 292.0 g (1.0 mole) of 1, The non-fluorine-containing diamine monomer of 3-bis(4-aminophenoxy)benzene and the strong polar aprotic organic solvent of 6042 milliliters of N, N-dimethylacetamide are put into reaction kettle, under room temperature, stir After dissolving completely, add 257.6 grams (0.8 moles) of 3,3',4,4'-tetracarboxybenzophenone dianhydride solid powder of aromatic dianhydride, and stir and react at room temperature for 1 hour to obtain a homogeneous transparent Fluorine-containing polyamic acid oligomer resin solution.

[0050] Add 8.0 moles of acetic anhydride dehydrating agent and 0.8 moles of triethylamine catalyst to the resin solution of the above-mentioned fluorine-containing polyamic acid oligomers, stir and react at room temperature for 1 hour, heat up to 80°C-100°C, and react with high-speed stirring After 3 hours, add 48336 mi...

Embodiment 2

[0058] 71.4 grams (0.1 moles) of 2,2-bis[4-(4-amino-2-trifluoromethylphenoxy)phenyl]hexafluoropropane and 42.8 grams (0.1 moles) of 1,3-bis(4 -Amino-2-trifluoromethylphenoxy) fluorine-containing diamine monomer of benzene, 4.1 grams (0.01 moles) of 2,2-bis[4-(4-aminophenoxy)phenyl]propane and 2.0 Gram (0.01 mole) 3, the non-fluorinated diamine monomer of 4 '-diaminodiphenyl ether and the strong polar aprotic organic solvent of 1120 milliliters of N-methyl-2-pyrrolidone are put into reaction kettle, at room temperature After stirring and dissolving completely, add 62.0 grams (0.2 moles) of 3,3',4,4'-tetracarboxydiphenyl ether dianhydride and 41.6 grams (0.08 moles) of 2,2-bis[4-(3,4- The aromatic dianhydride solid powder of dicarboxyphenoxy)phenyl]propane dianhydride is stirred and reacted at room temperature for 1 hour to obtain a homogeneous and transparent fluorine-containing polyamic acid oligomer resin solution.

[0059] Add 0.9 moles of acetic anhydride dehydrating agent...

Embodiment 3

[0067]71.4 grams (0.1 moles) of 2,2-bis[4-(4-amino-2-trifluoromethylphenoxy)phenyl]hexafluoropropane and 51.8 grams (0.1 moles) of 2,2-bis[4 -(4-aminophenoxy)phenyl]hexafluoropropane fluorinated diamine monomer, 41.0 grams (0.1 moles) of 2,2-bis[4-(4-aminophenoxy)phenyl]propane and 29.2 grams (0.1 moles) of 1,4-bis(3-aminophenoxy)benzene non-fluorinated diamine monomer and 1240 milliliters of N,N-dimethylformamide 2000 milliliters of N-methyl-2-pyrrolidone The strong polar aprotic organic solvent is put into the reactor, at room temperature, after stirring and dissolving completely, add 29.4 grams (0.1 mole) 3,3 ', 4,4'-tetracarboxy biphenyl dianhydride and 182.2 grams (0.35 mol) 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]propane dianhydride aromatic dianhydride solid powder, after stirring and reacting at room temperature for 1 hour, a homogeneous transparent fluorine-containing Polyamic acid oligomer resin solution.

[0068] Add 2.7 moles of acetic anhydride dehydrating agent,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile shear strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com