High-polymer three-dimensional amino-group substrate as well as preparation method and application thereof

A polymer and substrate technology, applied in biochemical equipment and methods, organic compound libraries, combinatorial chemistry, etc., can solve the problems of normal or no signal in the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

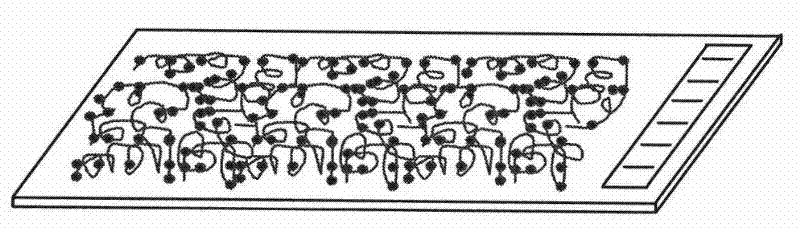

Method used

Image

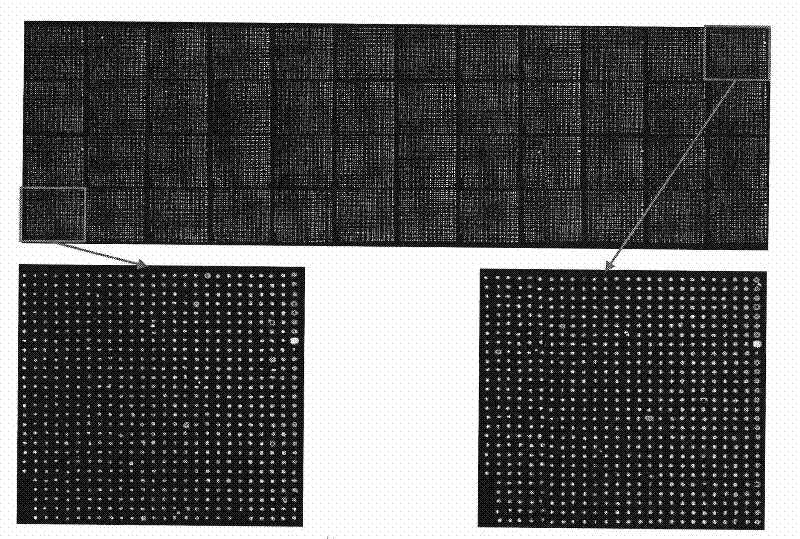

Examples

Embodiment 1

[0042] Embodiment 1, by absorbing chitosan on the slide sheet base, prepare chitin substrate

[0043] 1. Pretreatment of glass substrate

[0044] Slide slides in Piranha solution (concentrated H 2 SO 4 / 30%H 2 o 2 , V / V=7:3) soaked overnight, then washed with deionized water, clean; vacuum baked in a vacuum oven at 120 degrees for 1h;

[0045] 2. Adsorption of chitosan polymer

[0046] The molecular weight of chitosan used is 310,000-375,000 Da (high molecular weight);

[0047] Chitosan reaction solution: be the 0.1X PBS damping fluid of the chitosan that final concentration is 0.1% (mass percentage composition), described final concentration is the concentration of chitosan in chitosan reaction solution; Chitosan The pH of the reaction solution was adjusted to 6.0.

[0048] Immerse the clean hydrophobic glass slide base obtained in step 1 into the chitosan reaction solution, soak for 30 hours at 30°C and shake at a speed of 120rpm; stop soaking, wash the slide with dei...

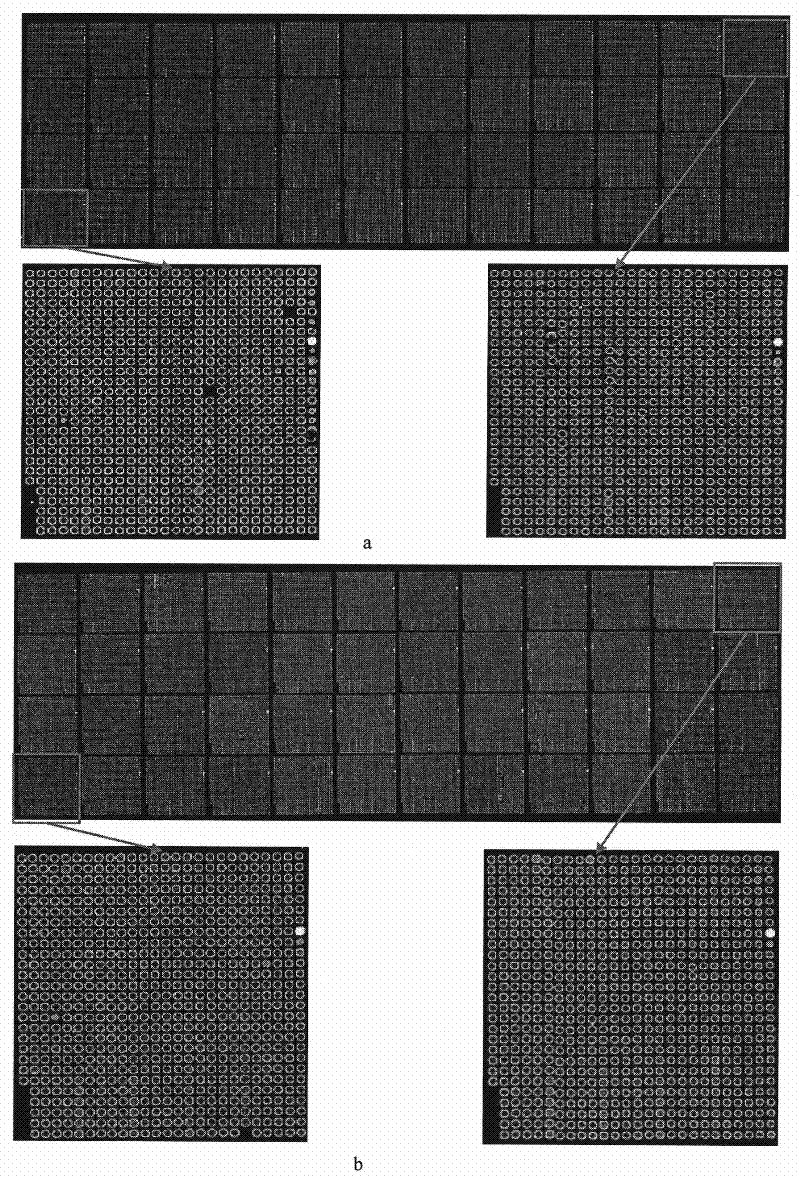

Embodiment 2

[0050] Embodiment 2, by absorbing chitosan on the slide sheet base, prepare chitin substrate

[0051] 1. Pretreatment of glass substrate

[0052] With experiment 1 in embodiment 1;

[0053] 2. Adsorption of chitosan polymer

[0054] The molecular weight of chitosan used is 50,000-190,000 Da (high molecular weight);

[0055] Chitosan reaction solution: be the 0.1X PBS damping fluid of the chitosan that final concentration is 0.3% (mass percentage composition), described final concentration is the concentration of chitosan in chitosan reaction solution; Chitosan The pH of the reaction solution was adjusted to 5.0.

[0056] Immerse the clean hydrophobic glass slide base obtained in step 1 in the chitosan reaction solution, soak for 0.5 hours at 10°C and shake at a speed of 120rpm; stop soaking, wash the slide with deionized water, and dry it. Get the chitin substrate.

Embodiment 3

[0057] Embodiment 3, by absorbing chitosan on the slide sheet base, prepare chitin substrate

[0058] 1. Pretreatment of glass substrate

[0059] With experiment 1 in embodiment 1;

[0060] 2. Adsorption of chitosan polymer

[0061] The molecular weight of chitosan used is 190,000-310,000 Da (high molecular weight);

[0062] Chitosan reaction solution: be the 0.1X PBS damping fluid of the chitosan that final concentration is 0.001% (mass percentage composition), described final concentration is the concentration of chitosan in chitosan reaction solution; Chitosan The pH of the reaction solution was adjusted to 6.0.

[0063] Immerse the clean hydrophobic glass slide base obtained in step 1 in the chitosan reaction solution, soak for 15 hours at 50°C and shake at a speed of 120rpm; stop soaking, wash the slide with deionized water, and dry it. Get the chitin substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com