Surface processing technique for bacterium resistance, erosion resistance and tarnish resistance of aluminum or aluminum alloy material

An aluminum alloy material and surface treatment technology, applied in the direction of surface reaction electrolytic coating, electrolytic coating, anodic oxidation, etc., can solve the problem of easy discoloration and achieve excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

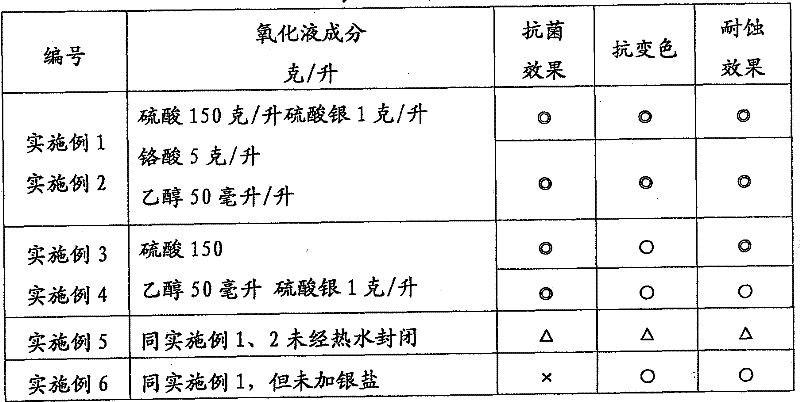

[0021] L1 (pure aluminum plate) plate 1mm thick, 50×50mm 2 The test plate, after acid degreasing, in H 2 SO 4 150 g / L, 5 g / L chromic acid, 1 g / L silver sulfate, 50 mL / L ethanol, and 50 mL / L ethanol, pass positive and negative alternating currents in positive and negative directions for 6 seconds each, voltage 18 volts, temperature 18°C (constant temperature) Oxidation under low temperature for 15 minutes, film thickness, antibacterial performance, anti-discoloration and other effects. See Table 1.

Embodiment 2

[0023] 6063 profile (square pipe material), wall thickness 0.8mm, cut into 50×50mm test pieces as samples. In the solution of 150 g / L sulfuric acid, 5 g / L chromic acid, 1 g / L silver sulfate, and 50 mL / L ethanol, the positive and negative charging and changing currents are passed in the solution, and the positive and negative directions are 4 seconds each, and the current density is 2 A / dm 2 , voltage 15-18 volts, time 15 minutes, temperature 18 ° C (constant temperature), after oxidation, in pure water, heated to 90-95 ° C, soaked for 10-15 minutes, its antibacterial, anti-corrosion, anti-discoloration effects are listed in Table 1 .

Embodiment 3

[0025] Test material, same as embodiment 1 is the L1 plate

[0026] The size of the test piece is the same, the pretreatment process and sealing process are the same, and the composition of the oxidation solution is:

[0027] 150 grams / liter of sulfuric acid, 1 gram / liter of silver sulfate, 50 milliliters / liter of ethanol, do not add chromic acid, the current form of passing through, current density and voltage are all identical with embodiment 1, for comparison.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com