Microfluid reactor based nano-particle preparation and particle controlled preparation process

A microfluidic reactor and nanoparticle technology, applied in the field of nanoparticles, can solve the problems of mass transfer and heat transfer that are difficult to be uniform and unrealizable, and achieve the effect of inhibiting Ostwall ripening and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

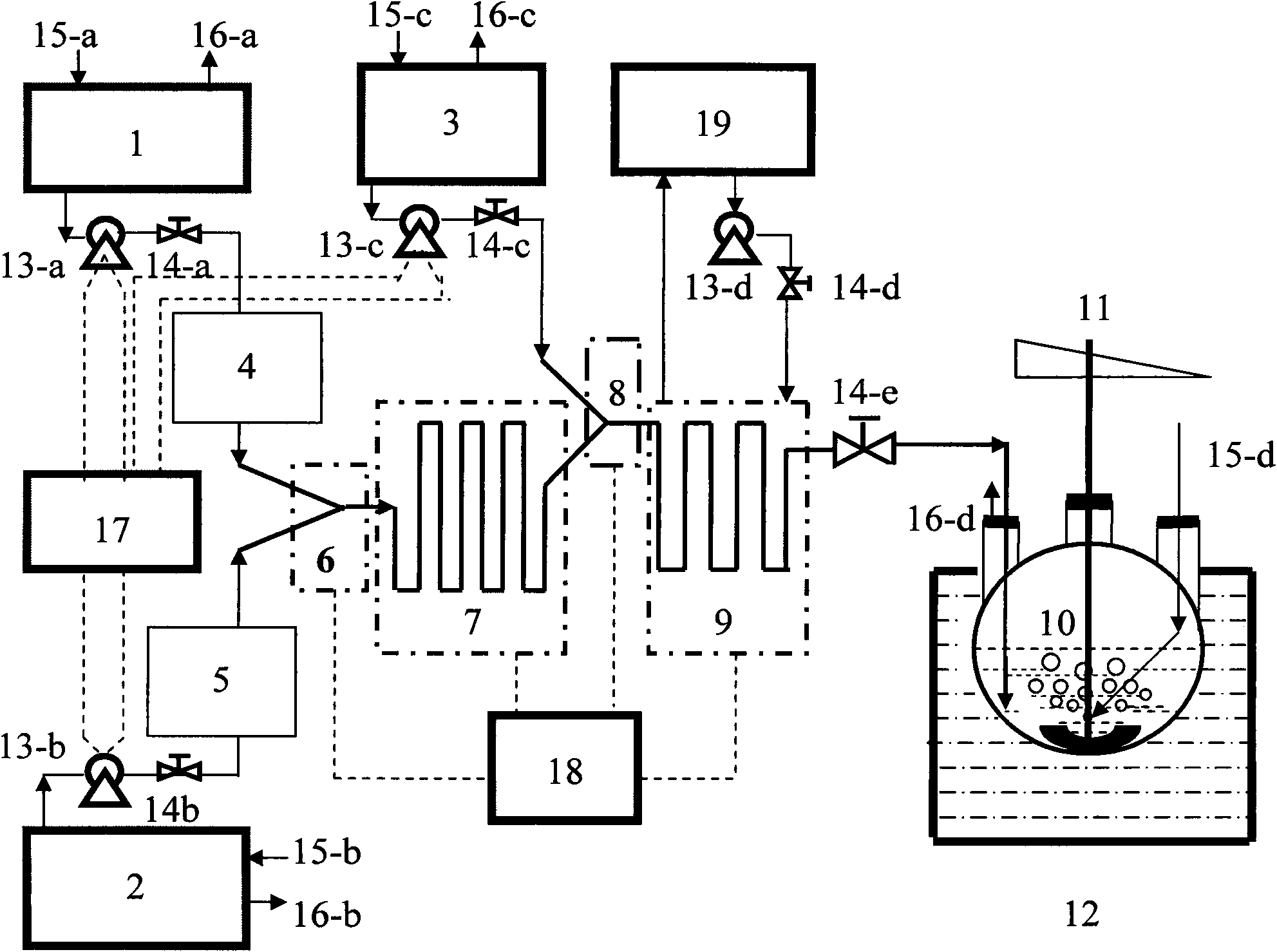

[0044] The invention provides a method for preparing amorphous cobalt nanoparticles with stable structure and performance by a microfluidic process. Its reactor contains figure 2 Two-layer chip-based microfluidic reactor. The construction material of 20-a is polyetheretherketone substrate (PEEK), and the construction material of 20-b is photosensitive resin SU8. Its microfluidic reactor is characterized in that: as figure 2 As shown in Fig. 1, the first layer is sealed with a thin copper sheet (100 μm thick) with high heat transfer coefficient in the microchannel structure of the 9th area in Fig. A microfluidic channel (25) is formed, and the second layer of microfluidic channel is sealed to form a microfluidic heat exchanger that can cool the first layer of reaction liquid through the cooling liquid. The rest of the reactor is the same as Figure 1 The composition shown is consistent. The flow channel for delivering the reaction solution to the first mixing reactor (6)...

Embodiment 2

[0048]The reactor structure in example 1 is modified as follows to be used for producing Co Sm alloy nanoparticles: wherein the wedge-shaped flow path width that reacts liquid is delivered to the first mixing reactor (6) shrinks gradually from 200 microns to 30 microns, and reacted liquid mixes Enter into the first micro-flow channel (7) of 60 microns wide, 600 microns deep after becoming micro-glue nucleus, the about 30cm of flow channel is long, makes nucleus grow into nanoparticle in this district; Then enters the second mixing reactor (8), Directly contact with the low-temperature termination solution to lower the temperature, the flow channel width of the micro-channel port for delivering the low-temperature termination solution is 60 microns, and the flow rate is 1 times that of the nanoparticle reaction solution. After mixing, it enters the second micro-channel with a width of 120 microns (9 ), about 15cm long, continue the low-temperature termination reaction, wherein t...

Embodiment 3

[0052] The reactor structure in Example 1 is modified as follows to produce Co nanoparticles with stable structure and performance: wherein the width of the wedge-shaped channel that delivers the reaction solution to the first mixing reactor (6) shrinks gradually from 200 μm to 30 μm. micron, the reaction solution is mixed and enters the first micro-channel (7) with a width of 60 microns, so that the nanoparticles grow up at a constant temperature, and the length of this area is shortened to 20 cm. The flow rate of the feed liquid is adjusted to 0.9 mL / min and the second mixing The reactor (8) and the second microchannel (9) were skipped, and the obtained nanoparticle solution at 50 °C was directly sprayed into a stirred product cryogenic collection containing 100 mL of ethanol and THF (20 V% ethanol content) at 4 °C device (10), the collector is protected under an inert gas (such as argon). According to the flow rate, the particle size of the sprayed droplets can be as small ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com