Semiconductor device, test mould and test method

A technology for testing molds and semiconductors, which is applied in the field of semiconductors, can solve the problems of increasing the test cost of semiconductor devices, increasing test costs, and large on-state voltage drop, and achieves the goals of reducing test cost, improving thermal resistance performance, and reducing on-state voltage drop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

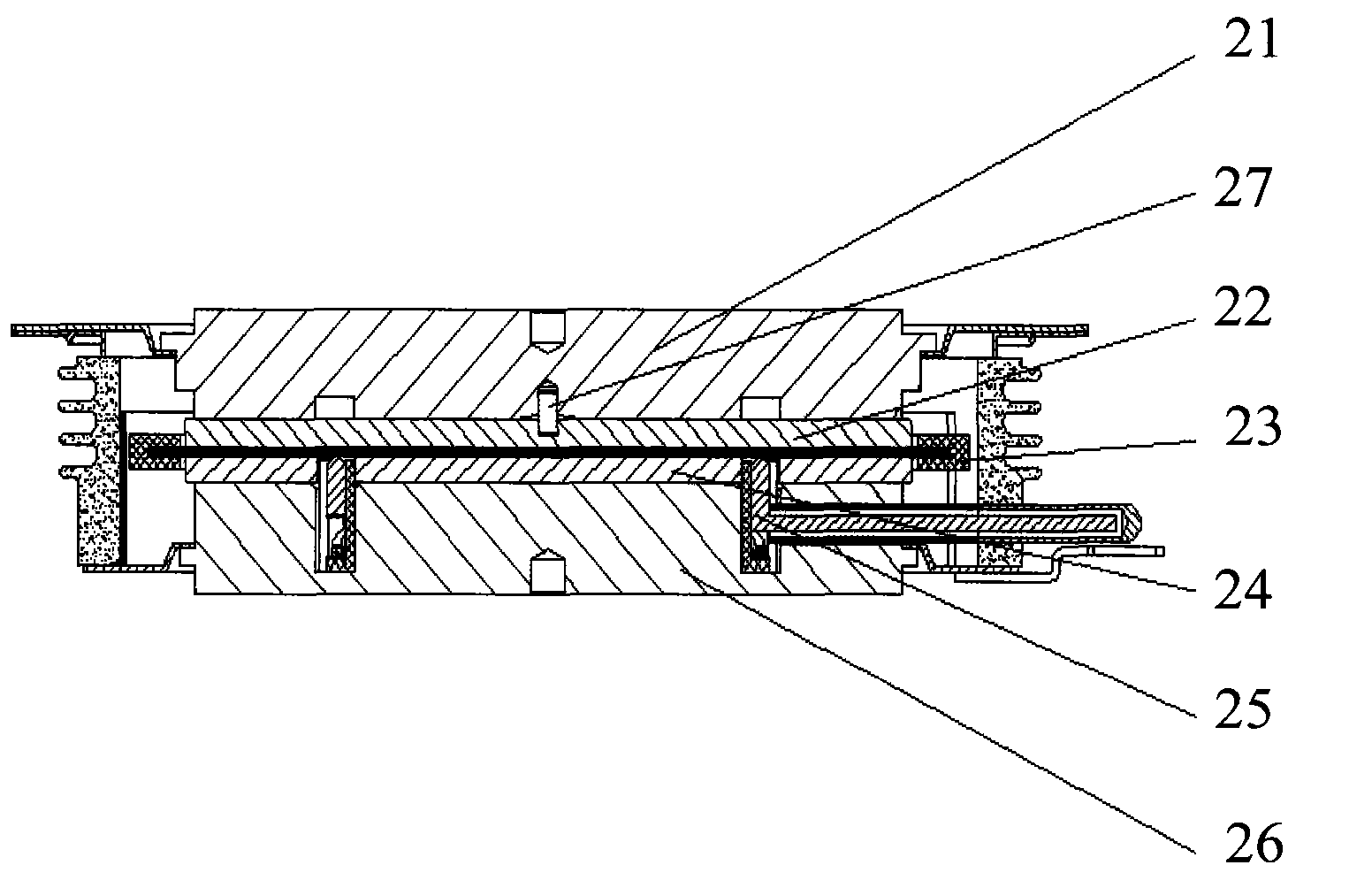

[0031] The technical solutions of the present invention will be described below with reference to the accompanying drawings and embodiments.

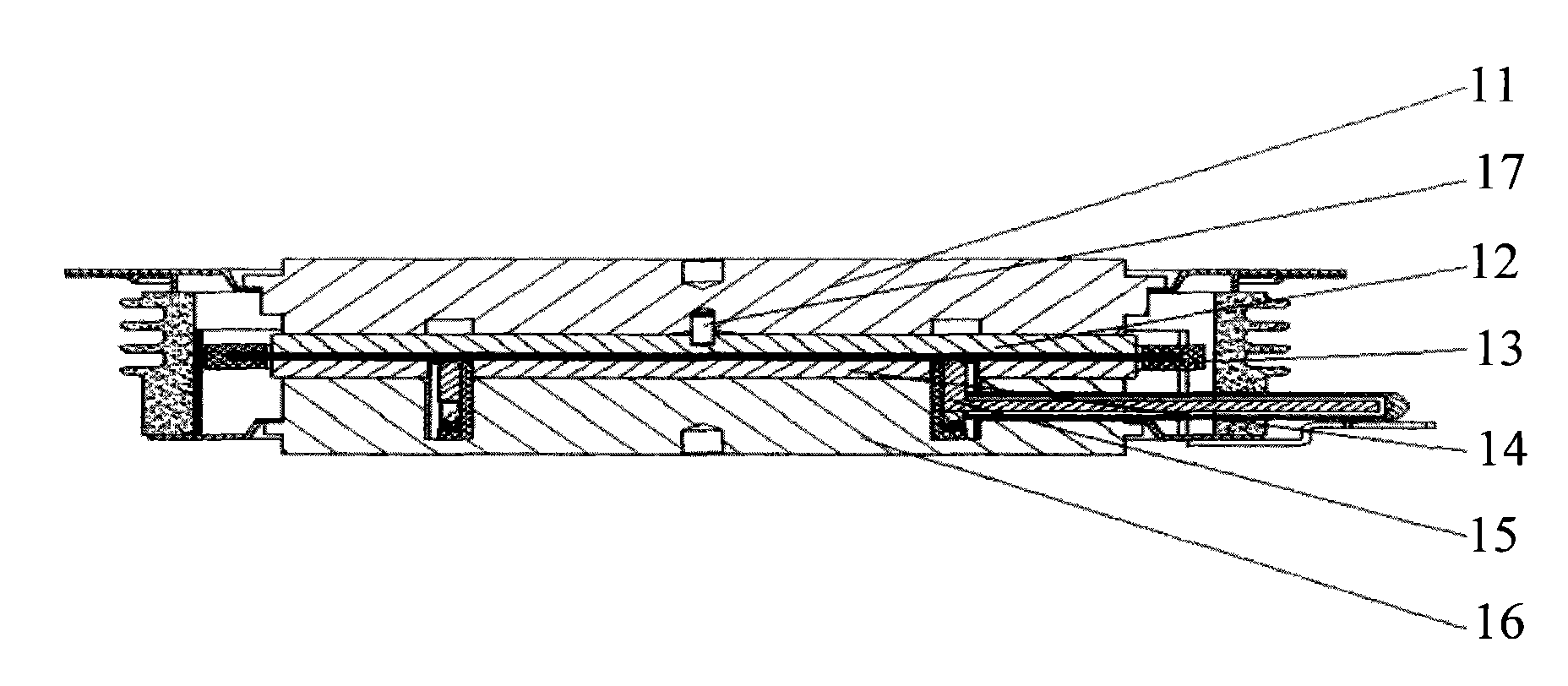

[0032] refer to figure 2 , is a schematic cross-sectional view of the structure of a semiconductor device according to an embodiment of the present invention.

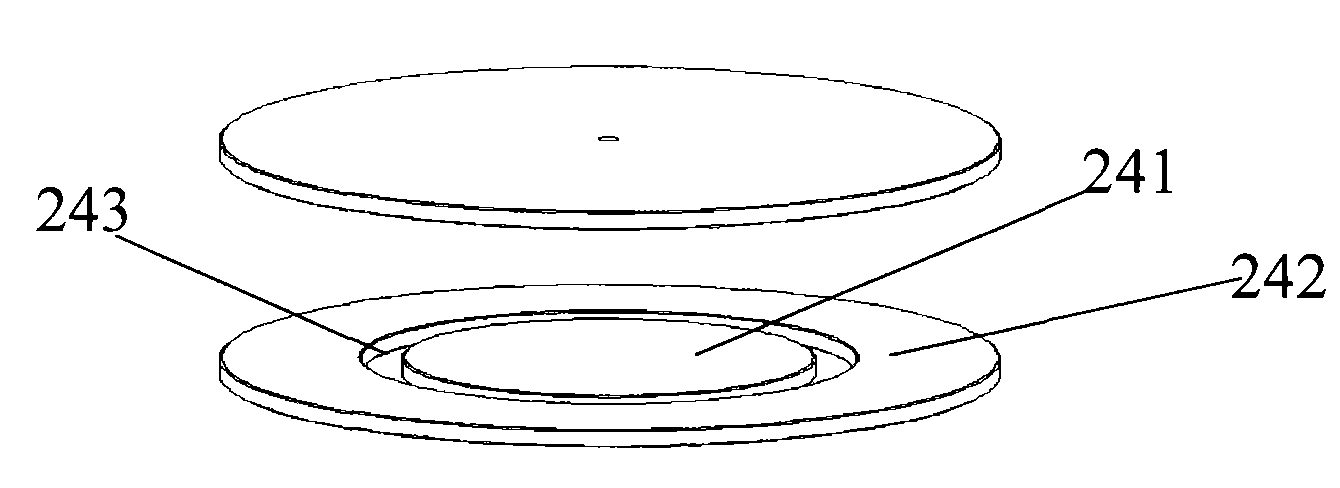

[0033] In the present embodiment, the semiconductor device adopts an aluminum alloy component group instead of a rhodium-plated molybdenum component group as a package component of a fully crimped device. The semiconductor device may include a tube cover 21 , an aluminum alloy anode 22 , a die chip 23 , an aluminum alloy cathode 24 , a gate electrode 25 and a stem 26 which are stacked and connected in sequence. The adjacent components of each layer are electrically connected and the gate electrode is also electrically connected to the die chip 23 . The connection method of each part is the same as that in the prior art.

[0034] The tube cover 21 is used as the anode of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com