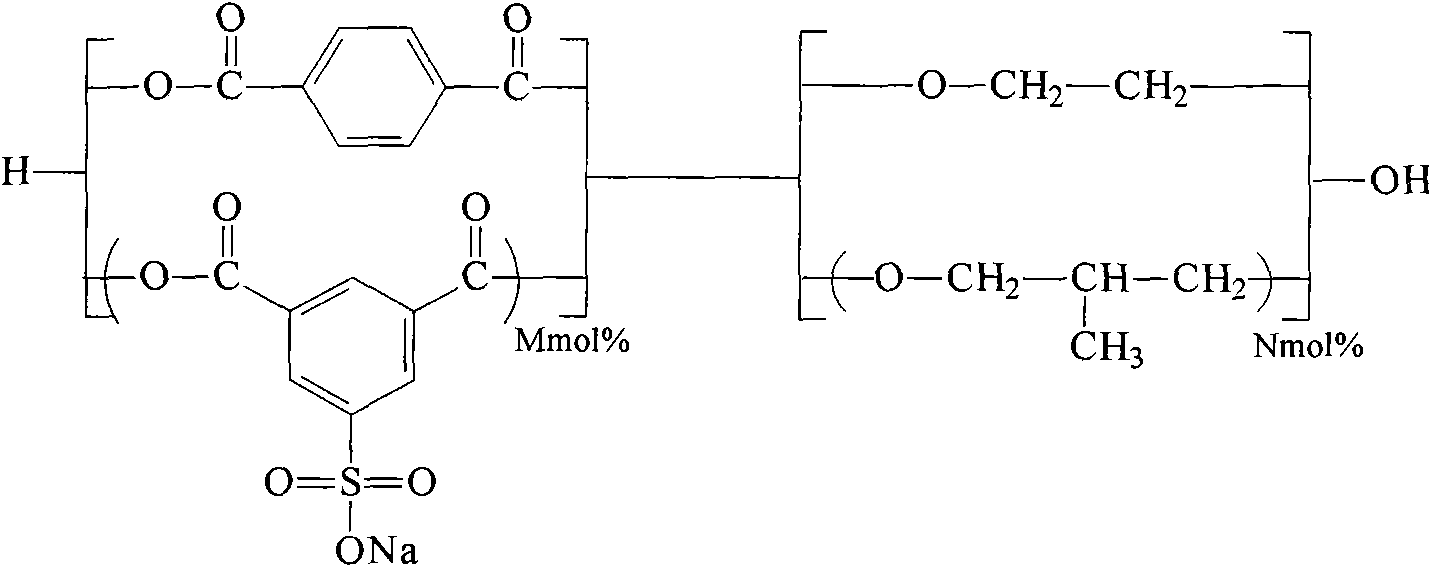

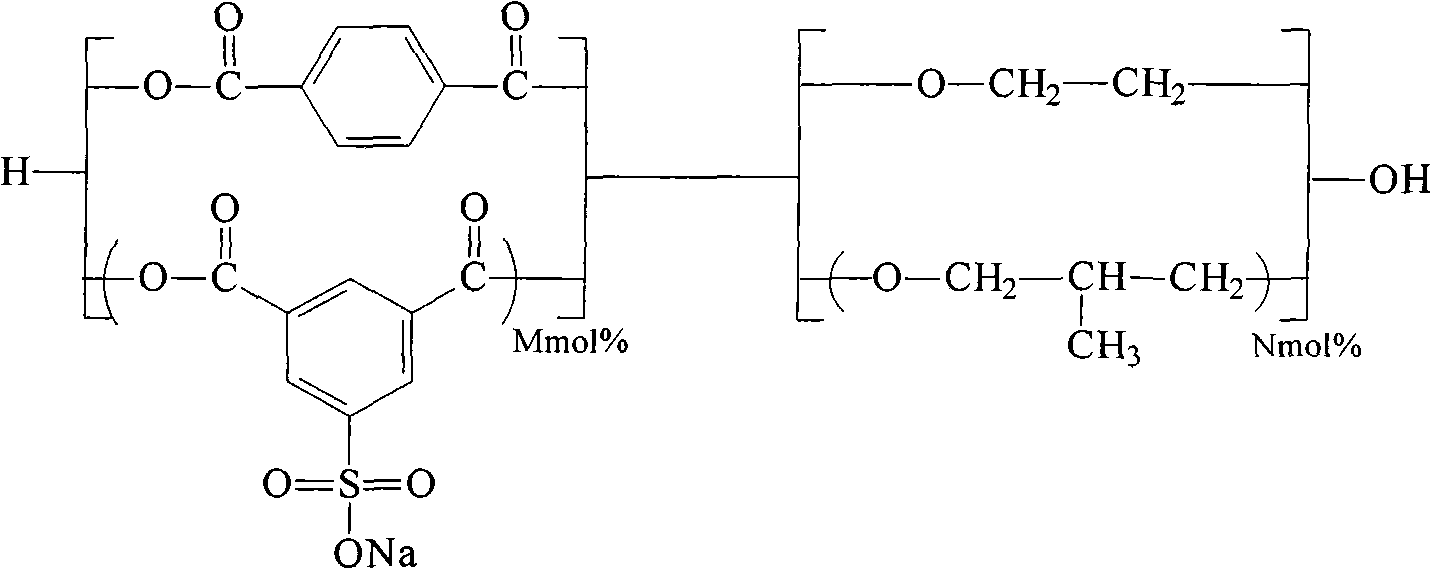

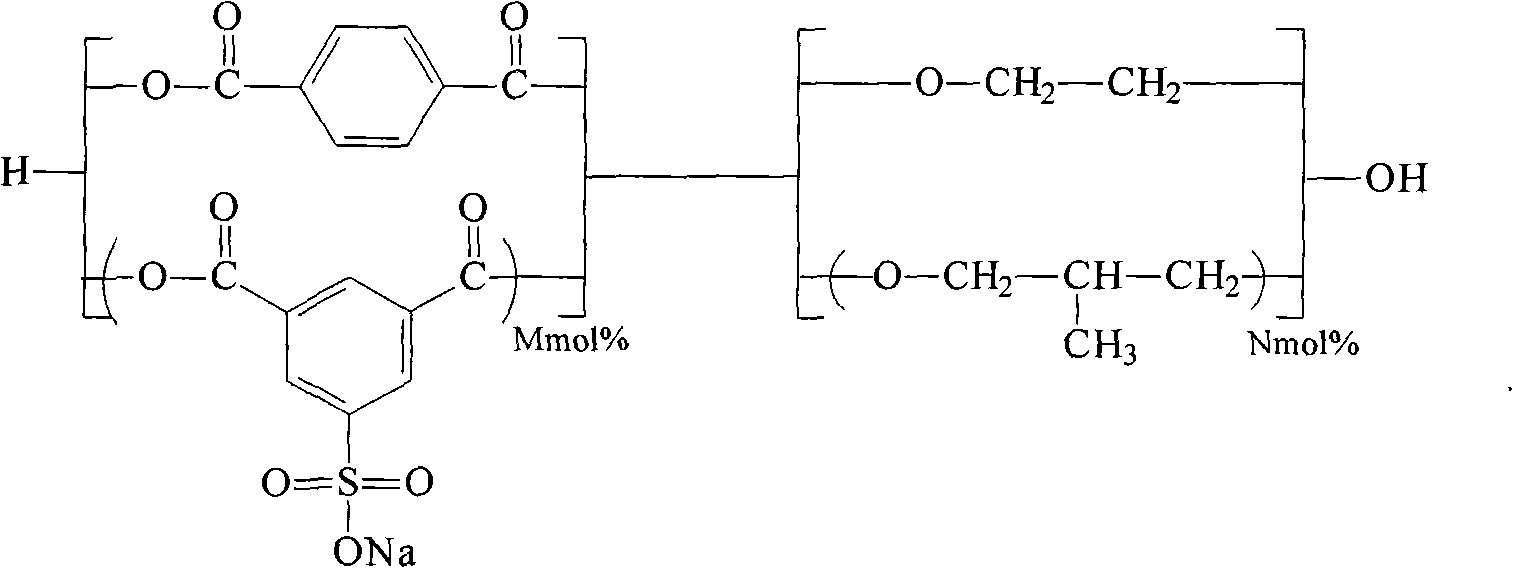

Side chain-containing aliphatic diol modified copolyester section and preparation method thereof

An aliphatic diol, copolyester technology, applied in the direction of one-component copolyester rayon, etc., can solve the problems of difficult polymerization, affecting the performance of spinnable fabrics, and unstable spinning. The effect of reducing crystallization performance and glass transition temperature, good market application value and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Using semi-continuous polymerization equipment, the first esterification tank is charged with 1 ton of PTA, 410 kg of EG and 74 kg of MPD for esterification, while adding 0.01 wt% antimony acetate catalyst and 0.02 wt% triphenyl phosphate (relative to PTA) , the reaction temperature is 260°C, after a residence time of 3 hours, the reactant enters the second esterification tank, and at the same time injects SIPE equivalent to 1.5mol% of PTA for further esterification, the reaction temperature is 250°C, and after a residence time of 2 hours, the reaction The product enters the polycondensation tank, the reaction temperature is 270-280° C., and stays for 3 hours. After the reaction is completed, the material is discharged and pelletized to obtain copolyester chips containing 10 mol% of MPD units and 1.5 mol% of SIPE units. The copolyester has an intrinsic viscosity of 0.486 and a melting point of 214°C.

Embodiment 2

[0033] Adopt semi-continuous polymerization equipment, the first esterification tank adds 1 ton of PTA and 410 kilograms of EG to carry out esterification, adds the antimony acetate catalyst of 0.01wt% and the triphenyl phosphate (relative to PTA) of 0.02wt% simultaneously, reaction temperature 260 ℃, after a residence time of 3 hours, the reactant enters the second esterification tank, and simultaneously injects 74 kg of MPD and SIPE equivalent to 1.5mol% of PTA for further esterification. The reaction temperature is 250 ℃, and after a residence time of 2 hours, the reaction The material enters the polycondensation tank, and the reaction temperature is 270-280° C., and stays for 3 hours. After the reaction is completed, the material is discharged and pelletized to obtain copolyester chips containing 6 mol% of MPD units and 1.5 mol% of SIPE units. The copolyester has an intrinsic viscosity of 0.592 and a melting point of 228°C.

Embodiment 3

[0035] Using semi-continuous polymerization equipment, the first esterification tank is charged with 1 ton of PTA, 410 kg of EG and 120 kg of MPD for esterification, while adding 0.01 wt% antimony acetate catalyst and 0.02 wt% triphenyl phosphate (relative to PTA) , the reaction temperature is 260°C, after a residence time of 3 hours, the reactant enters the second esterification tank, and at the same time injects SIPE equivalent to 1.5mol% of PTA for further esterification, the reaction temperature is 250°C, and after a residence time of 2 hours, the reaction The product enters the polycondensation tank, and the reaction temperature is 270-280° C., and stays for 3 hours. After the reaction is completed, the material is discharged and pelletized to obtain copolyester chips containing 15 mol% of MPD units and 1.5 mol% of SIPE units. The copolyester has an intrinsic viscosity of 0.476 and a melting point of 209°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com