Bulk-silicon processing method for manufacturing microstructure on basis of multiple masking layers

A processing method and technology for a masking layer, which are applied in the manufacture of microstructure devices, microstructure technology, microstructure devices, etc., can solve the problems that the process cannot be carried out smoothly, affecting the second photoresist coating, stacking and degumming, etc. , to avoid stacking and degumming, good compatibility, and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

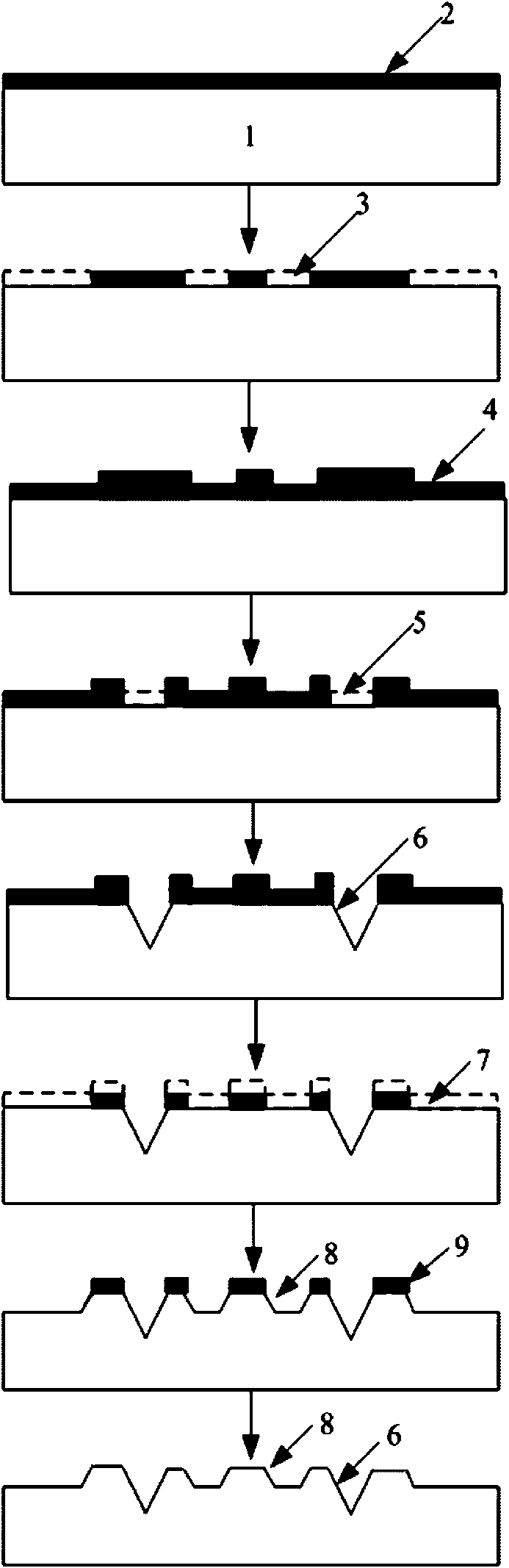

[0016] Example: Silicon dioxide is used as a masking layer to fabricate convex and concave microstructures by wet anisotropic etching technology

[0017] Step 1: Silicon Wafer Oxidation

[0018] Put wafer 1 into H 2 O 2 : H 2 SO 4 =1:3 solution was boiled to smoke for 10min, rinsed with deionized water for 15min, dried to obtain a hydrophobic surface; the treated silicon wafer was placed in a ZKLS-2A double-tube diffusion furnace, heated to 1180°C, and kept for 3.5 hours , a silicon dioxide masking layer 2 with a thickness of 1.5 μm is obtained on the silicon surface.

[0019] Step 2: Photolithography

[0020] Coat BP212 photoresist evenly on the silicon wafer obtained in step 1. The pre-spin coating time is 5s, the spin coating time is 30s, the pre-spin coating speed is 500rpm, and the spin coating speed is 3000rpm; the pre-bake BP212 photoresist is at 85℃ In the oven for 20min; after cooling, it was exposed on a BGJ-3 type lithography machine, and the light intensity o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com