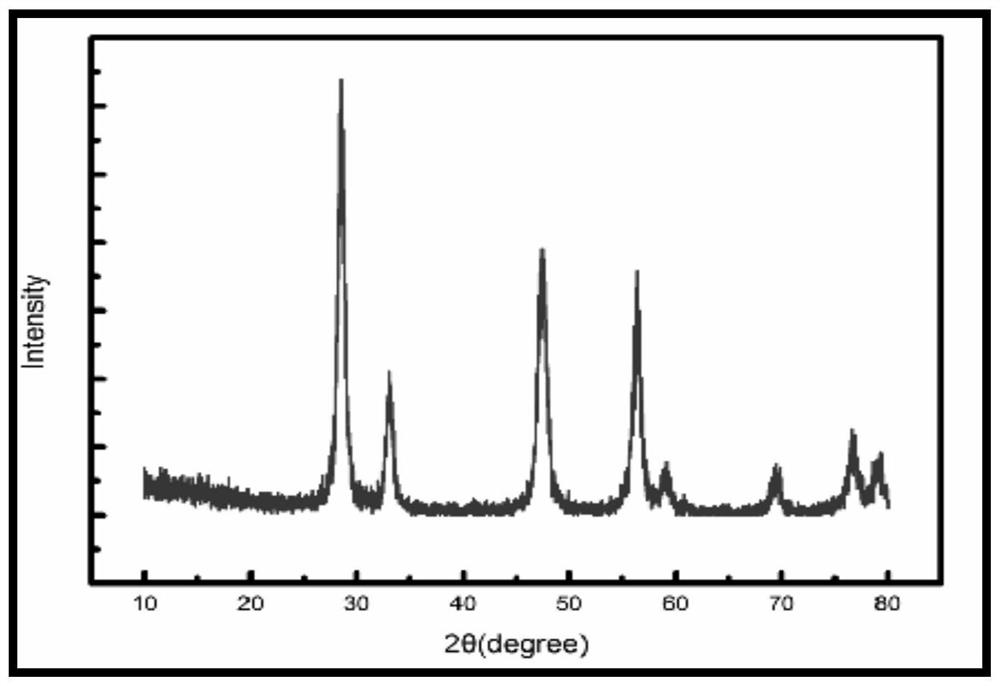

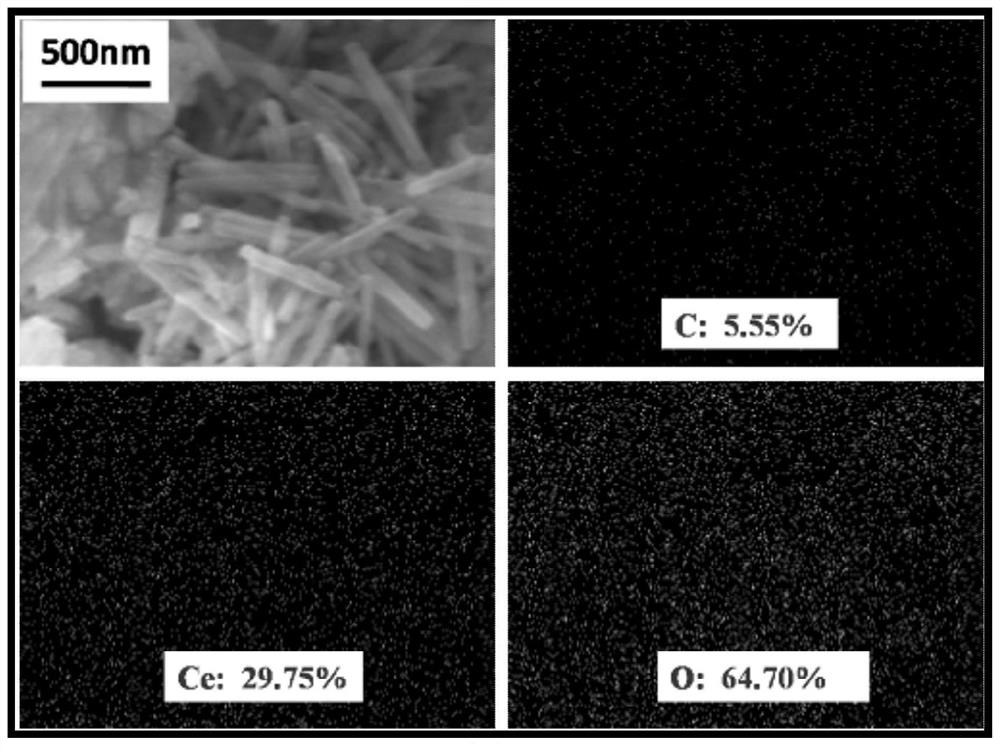

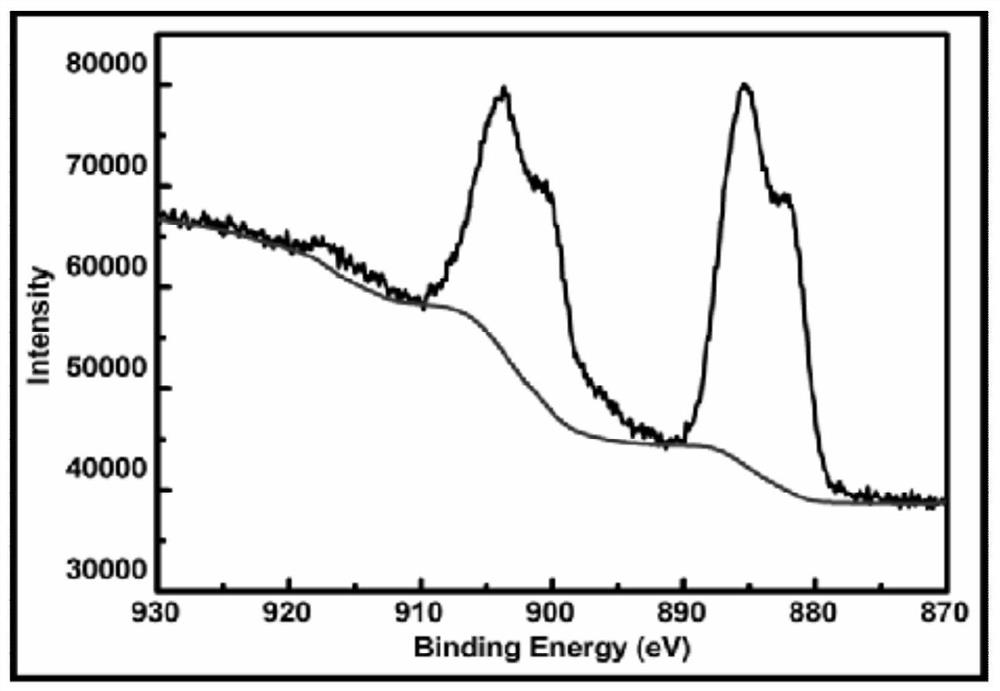

Amphiphilic rod-shaped nano-cerium oxide and amphiphilic rod-shaped ceo 2 /ce 3+ Preparation method of active nanoparticles

A nano-cerium oxide, amphiphilic technology, applied in the preparation/treatment of cerium oxide/cerium hydroxide, rare earth metal compounds, lanthanide oxides/hydroxides, etc., can solve the difficult preparation of rod-shaped nano-cerium oxide, Poor dispersion effect, low activity and other problems, to achieve the effect of easy process production, low energy consumption and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Product preparation

[0044] Weigh 7 g of citric acid and add it to 20 mL of deionized water, stir well until it is completely dissolved, and continue stirring at 50°C for 12 min. Weigh 5g of cerium nitrate hexahydrate and add it into 10mL of deionized water and stir until it is completely dissolved and mark it as No. 1, then weigh 3g of cerium nitrate hexahydrate and dissolve it in 10mL of deionized water and mark it as No. 2. Use an acid burette to add the No. 1 solution dropwise at a rate of 3d / s to the citric acid solution being cooled and stirred, and continue to stir for 10 minutes after the addition is complete. Then the precipitation solution was aged at 50°C for 8h, filtered under reduced pressure, washed with deionized water, dried at 70°C for 3h, placed in a muffle furnace and roasted at 450°C for 3h to obtain amphiphilic rod-shaped nano-cerium oxide .

[0045] Put the amphiphilic rod-shaped nano-cerium oxide into No. 2 solution and ultrasonically stir f...

Embodiment 2

[0050] Weigh 15g of citric acid and add it into 20mL of deionized water, stir well until it is completely dissolved, and continue stirring at 25°C for 12min. Weigh 3g of cerium chloride heptahydrate and add it into 15mL of deionized water and stir until it is completely dissolved and mark it as No. 1, then weigh 1g of cerium chloride heptahydrate and dissolve it in 15mL of deionized water and mark it as No. 2. Use an acid burette to add the No. 1 solution dropwise at a rate of 1 d / s to the cooling and stirring citric acid solution, and continue stirring for 10 minutes after the addition is complete. Then the precipitation solution was aged at 25°C for 8h, filtered under reduced pressure, washed with deionized water, dried at 70°C for 3h, placed in a muffle furnace at 500°C for 4h, and then the amphiphilic rod-shaped nano oxide was obtained. cerium.

[0051] Put the amphiphilic rod-shaped nano-cerium oxide into the No. 2 solution and ultrasonically stir for 8 hours, filter and...

Embodiment 3

[0053] Weigh 1.5g of sodium citrate and add it into 20mL of deionized water, stir well until it is completely dissolved, and continue stirring at 0°C for 10min. Weigh 2.17g of cerium nitrate hexahydrate and add it into 15mL of deionized water and stir until it is completely dissolved and mark it as No. 1, then weigh 1.96g of cerium nitrate hexahydrate and dissolve it in 15mL of deionized water and mark it as No. 2. Use an acid burette to add the cerium nitrate solution dropwise at a speed of 0.5 d / s to the sodium citrate solution being cooled and stirred, and continue stirring for 10 minutes after the addition is completed. Then the precipitation solution was aged at 0°C for 6h, filtered under reduced pressure, washed with deionized water, dried at 80°C for 2h, placed in a muffle furnace at 500°C for 2h, and then the amphiphilic rod-shaped nano oxide cerium.

[0054] Put the rod-shaped nano-cerium oxide into the No. 2 solution and stir it ultrasonically for 2 hours, filter an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com