Sapphire substrate and polishing method and application thereof

A sapphire substrate, sapphire technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of reducing the quantum luminous efficiency of the device, affecting the performance of the device, and high cost, increasing the internal quantum luminous efficiency and reducing the dislocation density. , the effect of alleviating stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) cutting to obtain a sapphire single crystal substrate sheet with a thickness of 300 microns;

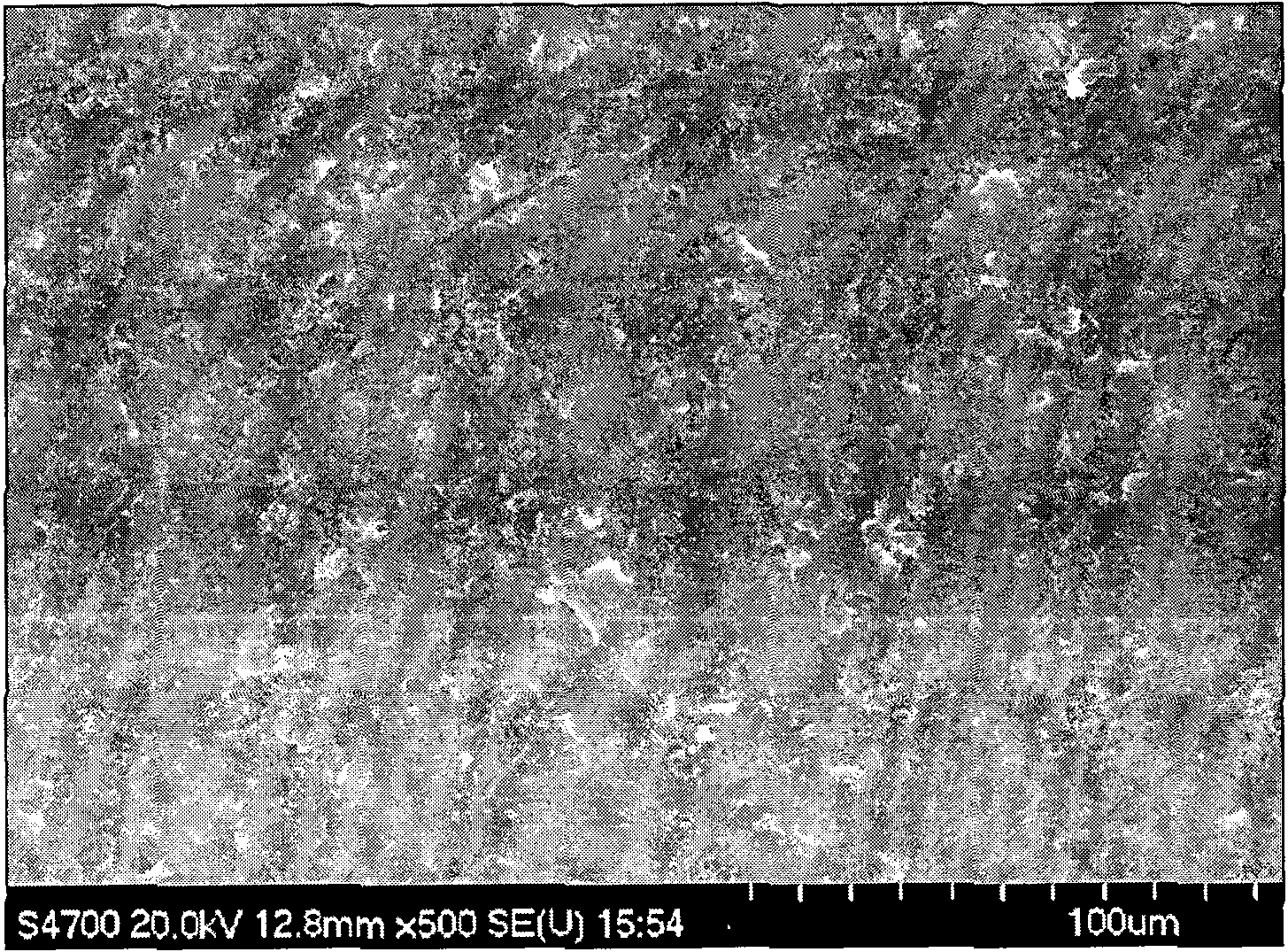

[0031] 2) Grinding with boron carbide with a particle size of about 1 micron until the thickness difference in the chip is reduced to less than 1 micron, and ultrasonically cleaning to obtain a sapphire substrate grinding chip with a rough structure on the surface, such as figure 1 shown;

[0032] 3) Etching the sapphire substrate grinding piece in the polishing agent to perform chemical polishing directly, the polishing temperature is 150 degrees Celsius, the polishing time is 24 hours, and the polishing pressure is about 0.5 MPa. The polishing agent is a mixture of NaOH and KOH, and their weight ratio is 1:1. The obtained substrate surface is as figure 2 and image 3 shown. The polished surface has a random and disordered concave pattern structure, the lateral dimension of the pattern depression is 10-30 microns, the vertical depth is 500 nanometers-2 microns, and th...

Embodiment 2

[0034] 1) cutting to obtain a sapphire single crystal substrate sheet with a thickness of 500 microns;

[0035] 2) Grinding with diamond with a particle size of about 0.5 micron until the thickness difference in the chip is reduced to less than 1 micron, and ultrasonically cleaning to obtain a sapphire substrate grinding chip with a rough structure on the surface;

[0036] 3) Etching the sapphire substrate grinding piece in the polishing agent to perform chemical polishing directly, the polishing temperature is 200 degrees Celsius, the polishing time is 18 hours, and the polishing pressure is about 1.0 MPa. The polishing agent contains NaOH, KOH, Na 2 SO 4 mixture, the weight fraction between them is 3:3:1. The obtained substrate surface has a random and disordered concave pattern structure, such as Figure 4 and Figure 5 shown. The lateral size of the depression in the pattern is 2-10 micrometers, the vertical depth is 100-500 nanometers, and the percentage of the surfa...

Embodiment 3

[0038] 1) cutting to obtain a sapphire single crystal substrate sheet with a thickness of 800 microns;

[0039] 2) Grinding with boron carbide with a particle size of about 3 microns until the thickness difference in the chip is reduced to less than 1 micron, and ultrasonically cleaning to obtain a sapphire substrate grinding chip with a rough structure on the surface;

[0040] 3) Etching the sapphire substrate grinding piece in the polishing agent to perform chemical polishing directly, the polishing temperature is 400 degrees Celsius, the polishing time is 4 hours, and the polishing pressure is about 10 MPa. The polishing agent is a mixture of NaOH, KOH and LiOH, and the weight ratio among them is 2:2:1. The surface of the obtained substrate has a random and disordered concave pattern structure, the lateral dimension of the pattern depression is 1-5 micrometers, the vertical depth is 50-100 nanometers, and the percentage of the surface area of the sapphire substrate is 50%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com