Preparation method of highly dispersive spindle-shaped nano titanium dioxide sol

A nano-titanium dioxide, high-dispersion technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of unsafe factors, obvious toxicity, etc., and achieve the effect of abundant sources, low cost and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

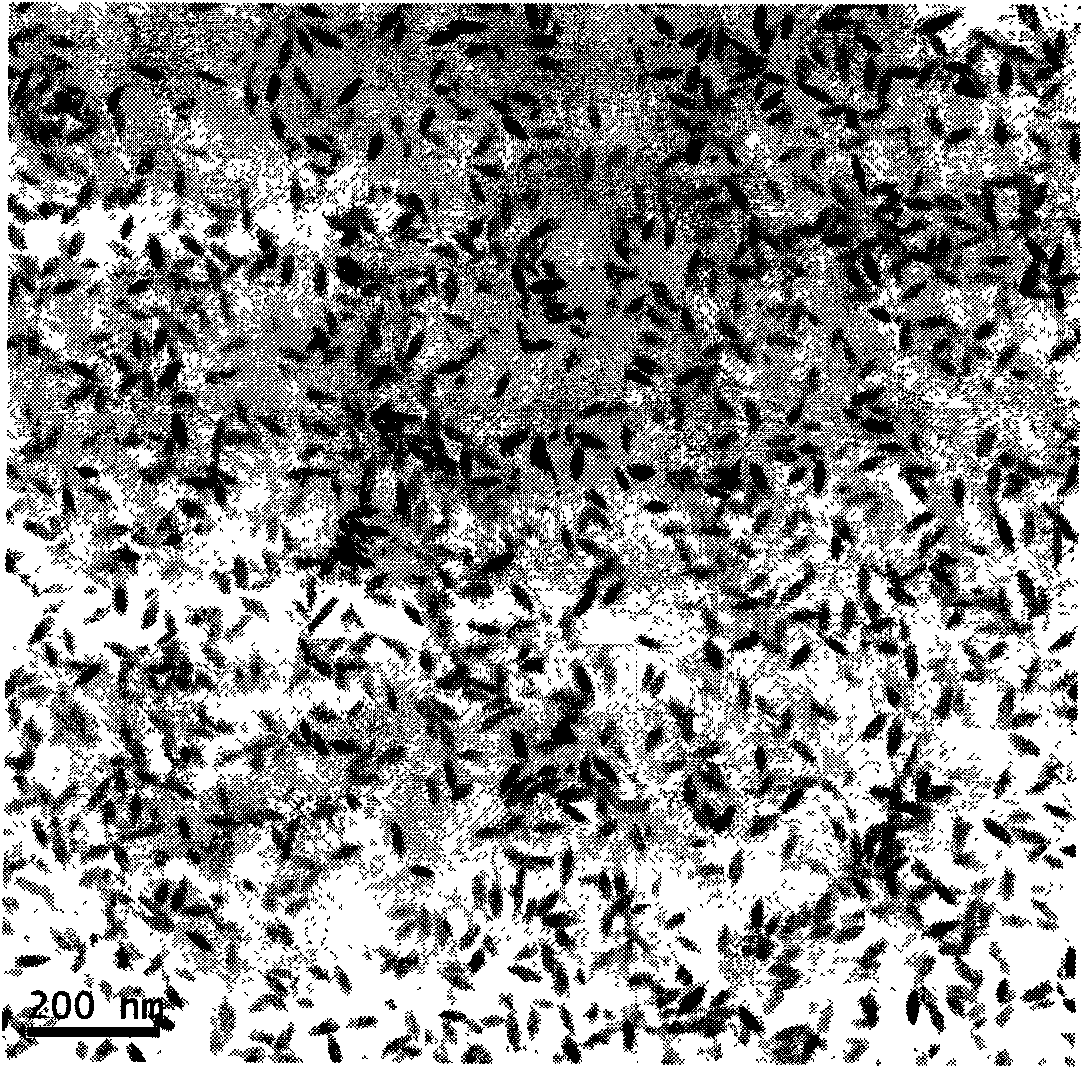

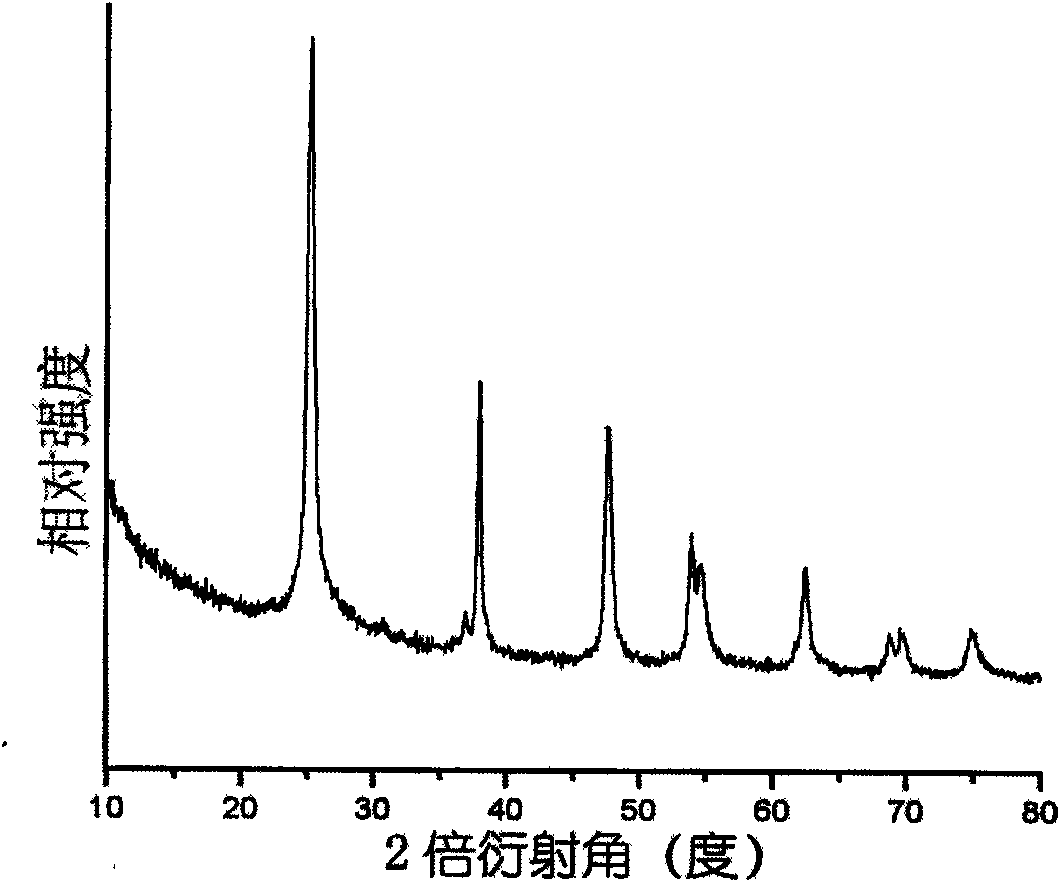

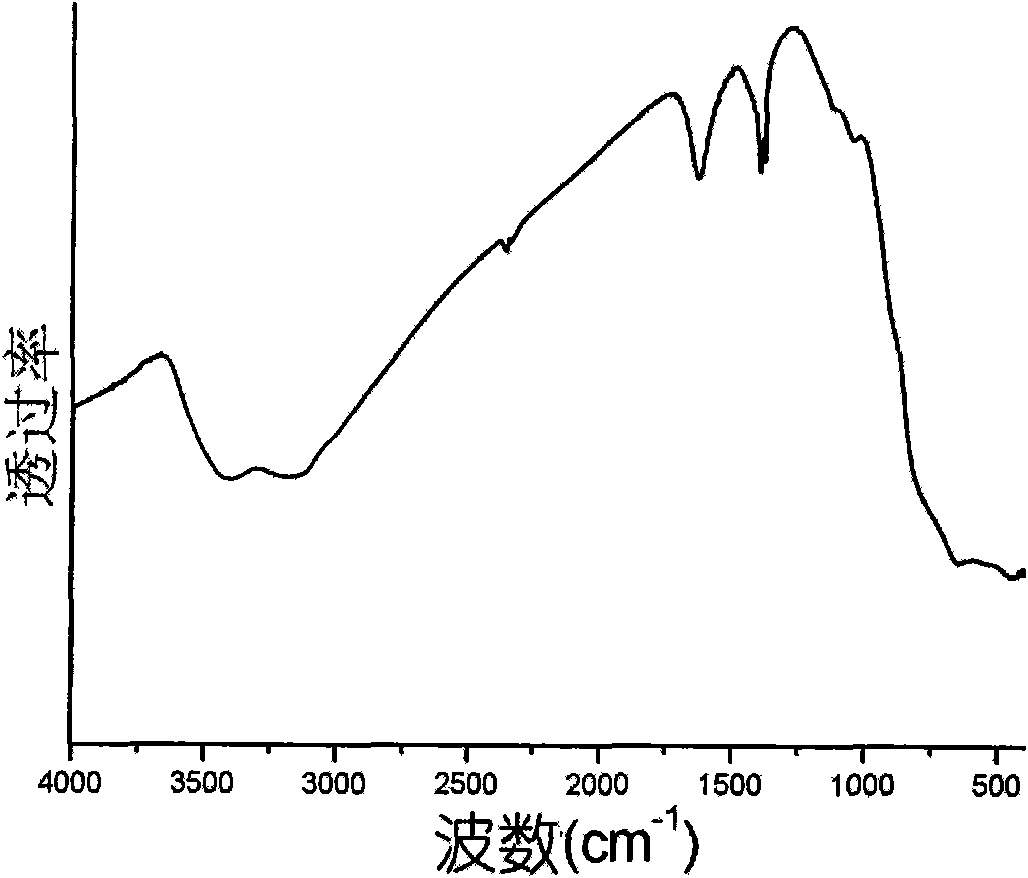

[0027] Weigh 3g of titanyl sulfate and dissolve it in 500ml of deionized water, stir at a speed of 800 rpm at room temperature, and add ammonia water with a mass concentration of 10% thereinto until the pH value is equal to 7.5. After 4 hours of continuous stirring, the resulting white precipitate was washed with deionized water and centrifuged 4 times at a speed of 8000. After mixing the centrifuged product with 600ml of deionized water, stir at a constant speed of 400 rpm, add hydrogen peroxide dropwise to adjust the pH value to 1, and continue stirring for 6 hours to obtain a highly dispersed fusiform nano-titanium dioxide sol. Such as figure 1 , TEM photos show clear highly dispersed spindle-shaped particles with a diameter of about 25nm and a length of about 50nm; as figure 2 , the XRD pattern of the xerogel corresponds to the JCPDS card numbered 73-1764, indicating that its crystal form is anatase; image 3 It is the Fourier transform infrared spectrogram of nano-tita...

Embodiment 2

[0029] Weigh 1 g of titanyl sulfate and dissolve it in 200 ml of deionized water, stir at a speed of 600 rpm at room temperature, and add ammonia water with a mass concentration of 30% dropwise until the pH value is equal to 11. After continuous stirring for 6 hours, the resulting white precipitate was washed with deionized water and centrifuged 4 times at a speed of 5000. Mix the centrifuged product with 400ml of deionized water, stir at a constant speed of 400 rpm, add hydrogen peroxide dropwise to adjust the pH to 5, and continue stirring for 5 hours to obtain a highly dispersed fusiform nano-titanium dioxide sol. The XRD pattern of the xerogel shows that its crystal form is anatase, and the TEM photo shows well-dispersed spindle-shaped particles with a diameter of about 20nm and a length of about 40nm.

Embodiment 3

[0031] Weigh 5g of titanyl sulfate and dissolve it in 500ml of deionized water, stir at a speed of 500 rpm at room temperature, and add ammonia water with a mass concentration of 50% dropwise until the pH value is equal to 8. After continuous stirring for 8 hours, the resulting white precipitate was washed with deionized water and centrifuged 4 times at a speed of 6000. After mixing the centrifuged product with 300ml of deionized water, stir at a constant speed of 400 rpm, adjust the pH value to 6, and continue stirring for 4 hours to obtain a highly dispersed fusiform nano-titanium dioxide sol. The XRD pattern of the xerogel shows that its crystal form is anatase, and the TEM photo shows clear and highly dispersed spindle-shaped particles with a diameter of 25nm and a length of 50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com