Method for protecting reforming catalyst of molten carbonate fuel cell and applications thereof

A reforming catalyst, molten carbonate technology, applied in molten electrolyte fuel cells, fuel cells, catalyst protection and other directions, can solve the problems of short running time, poor repeatability, poor alkali resistance effect, etc., to improve the running time , the effect of prolonging the operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

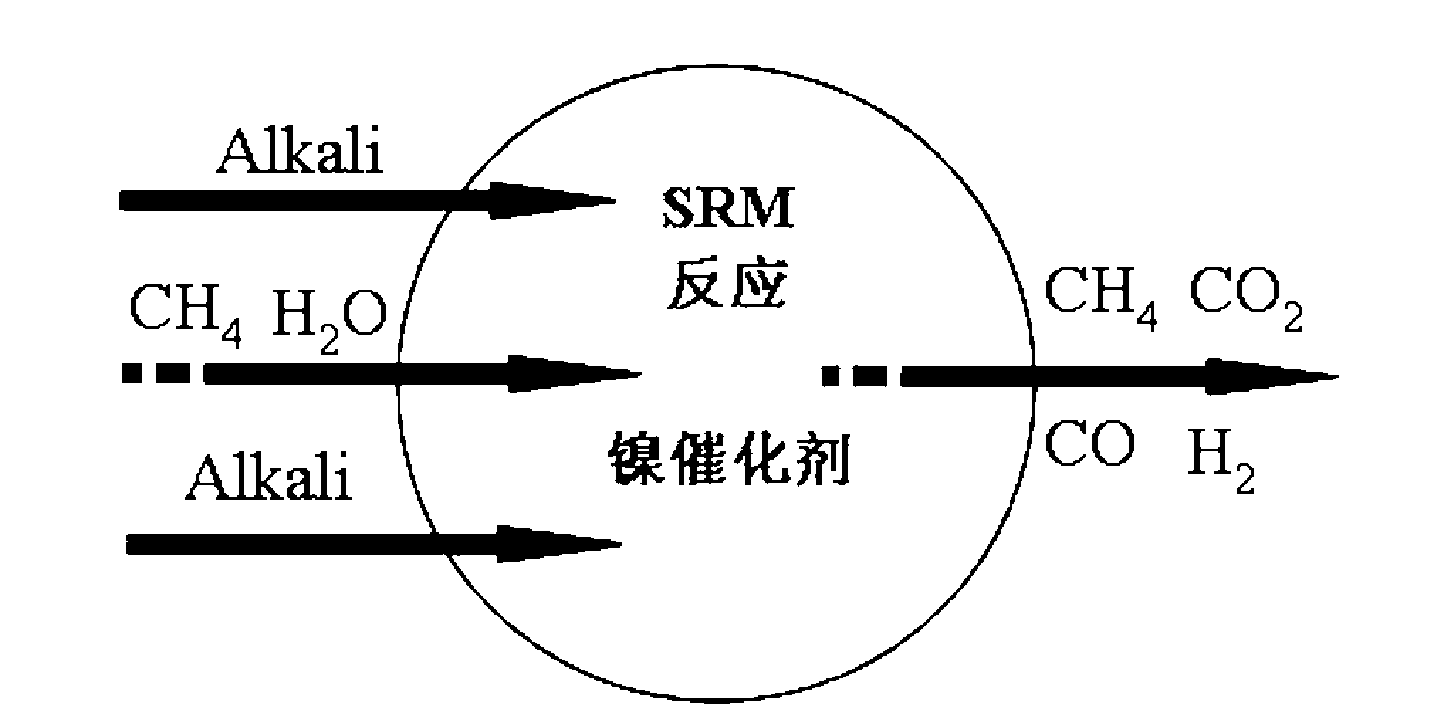

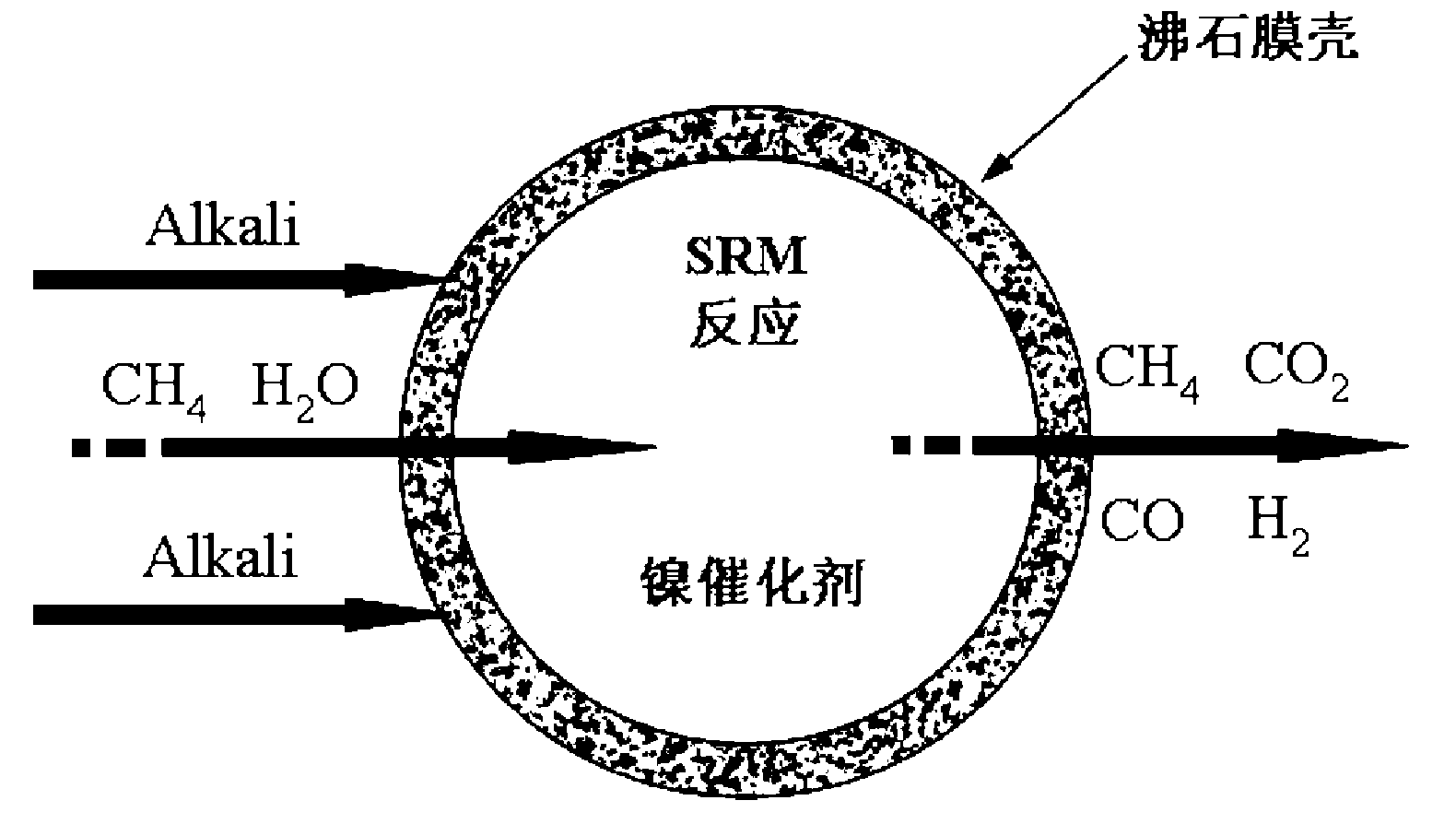

[0028] Embodiment 1: the preparation of core-shell type catalyst

[0029] Carrier pretreatment: porous γ-Al with a particle size of 3 mm 2 o 3 The carrier was washed with deionized water several times, ultrasonically oscillated, and dried at 100°C for later use.

[0030] Preparation of nickel-based catalyst by impregnation method: Quantitative γ-Al 2 o 3 The carrier is impregnated with 5-10wt% Ni(NO 3 ) 2 ·6H 2 O aqueous solution, fully stirred, dried at 80°C, and burned in a muffle furnace at 650°C with a heating rate of 5K / min.

[0031] Preparation of Sil-1 zeolite seeds and their covalent coupling to supports: according to TPAOH:SiO 2 :H 2 O=30:90:2800 molar ratio to prepare Sil-1 zeolite seed crystal precursor solution, wherein tetraethyl orthosilicate (TEOS) is the silicon source, tetrapropyl ammonium hydroxide (TPAOH) is the organic template, after fully mixing Stir at room temperature for 24 hours, pour into a stainless steel crystallization kettle with PTFE li...

Embodiment 2

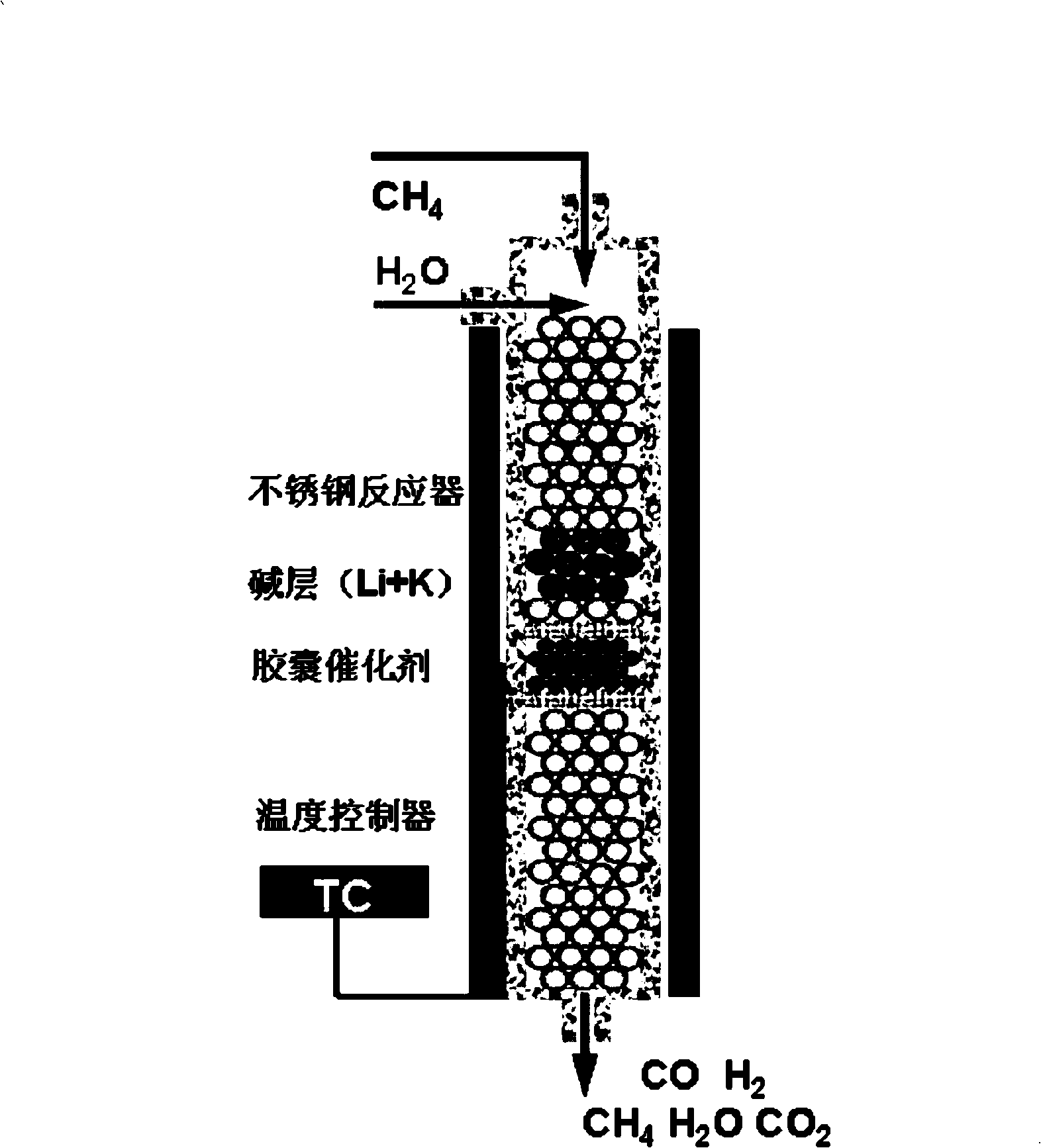

[0034] Embodiment 2: test of reforming reaction containing alkali outside the pool

[0035] The purpose of this test is to test the alkali poisoning resistance of the core-shell catalyst. The reactor adopts a stainless steel tube with an inner diameter of 6mm and a length of 400mm. The type catalyst is placed on the packing layer, and quartz wool is placed between the catalyst and the packing layer, so that the catalyst layer is in the constant temperature zone of the heating furnace, and 62mol% Li 2 CO 3 and 38 mol% K 2 CO 3 The 20%wt inert filler layer impregnated with alkali is placed on the catalyst bed; before the reaction, the system feeds 20ml / min of hydrogen to carry out catalyst reduction for 4h, press H 2 O / CH 4 Ratio 3:1 from the upper port of the reactor, the reaction temperature was controlled at 650°C, and gas chromatography (GC7890, TCD detector) was used to detect H 2 , CO, CO 2 and CH 4 Component content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com