Method of adding antifoaming agent to cationic electrodeposition paint and additive for use therein

A technology of cationic electrodeposition and defoamer, which is applied in electrolytic coatings, electrophoretic coatings, epoxy resin coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

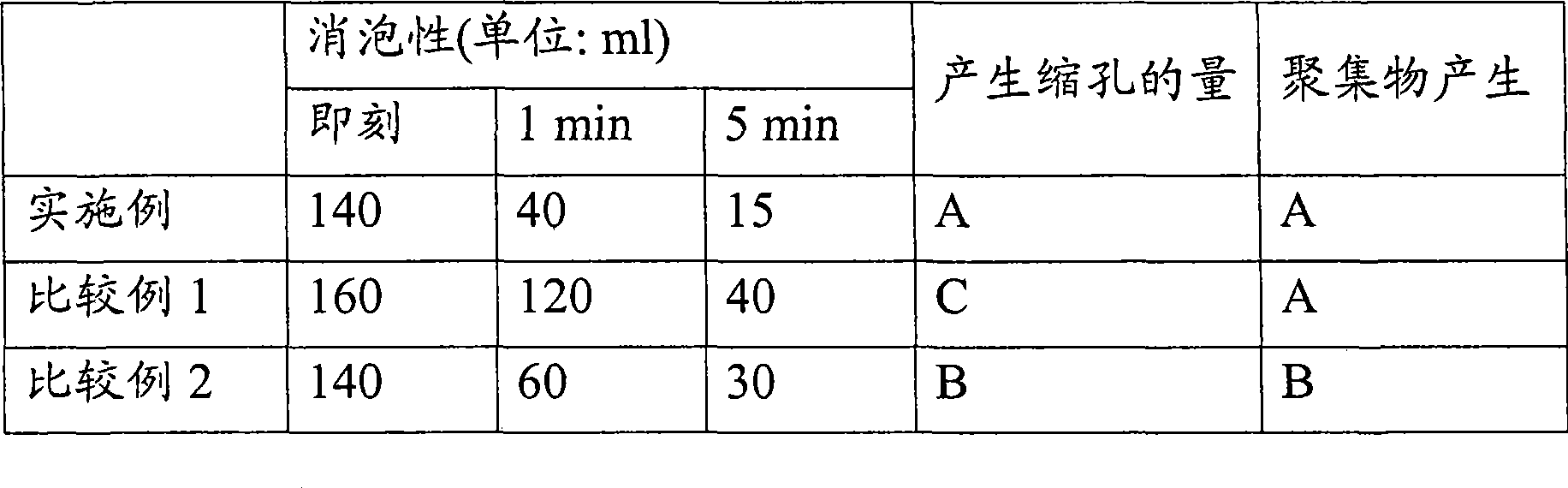

Examples

specific example

[0039] Specific examples include: butylamine, octylamine, diethylamine, dibutylamine, methylbutylamine, monoethanolamine, diethanolamine, N-methylethanolamine, triethylamine hydrochloride, N,N-dimethylethanolamine acetic acid salt, a mixture of diethyl sulfide and acetic acid, etc.; in addition, there are secondary amines that block primary amines such as ketimine of aminoethylethanolamine and diketimine of diethylenetriamine (jikechimin diketimine). Various amines may be used in combination.

[0040] Hardener

[0041] The curing agent used in the present invention is preferably blocked polyisocyanate, which is obtained by reacting polyisocyanate with a blocking agent. Herein, polyisocyanate means a compound having two or more isocyanate groups in a molecule. Examples of the polyisocyanate may be any of aliphatic, cycloaliphatic, aromatic, aromatic-cycloaliphatic, and the like.

[0042] Specific examples of the polyisocyanate include aromatic diisocyanates such as toluen...

preparation example 1

[0070] (Preparation of pigment dispersion resin paint with sulfonium base)

[0071] Add 222.0 parts of isophorone diisocyanate (hereinafter referred to as IPDI) into a reactor equipped with a stirrer, condenser, nitrogen conduit and thermometer, dilute with 39.1 parts of methyl isobutyl ketone (hereinafter referred to as MIBK), Then add 0.2 part of dibutyltin laurate. Then, after the temperature was raised to 50° C., 131.5 parts of 2-ethylhexanol were added dropwise in a dry nitrogen atmosphere over 2 hours while stirring. The reaction temperature was maintained at 50°C with appropriate cooling. IPDI half-blocked with 2-ethylhexanol was thus obtained.

[0072] Then, 382.2 parts of bisphenol A epoxy resin having an epoxy equivalent of 188 (manufactured by Dow Chemical Company) and 117.8 parts of bisphenol A were charged in a suitable reactor and heated to 150°C to 160°C under a nitrogen atmosphere. The reaction mixture was reacted at 150°C-160°C for about 1 hour, and then cool...

Embodiment 1

[0074] Preparation of mixture of defoamer and pigment dispersion resin

[0075] 100 g of an antifoamer (Surfynol 124; acetylene diol antifoamer, manufactured by Air Products and Chemicals, Inc.), the pigment dispersion resin varnish synthesized in Preparation Example 1 were mixed in such an amount that the nonvolatile component content was 30% by weight. (solid content of 100 g) and pure water were weighed into a beaker, and the mixture was stirred and dispersed by a stirrer to obtain a mixed additive in which an antifoaming agent was kneaded with a dispersion resin.

[0076] Preparation of Electrodeposition Coatings

[0077] Then, the above mixed additive (concentrate equivalent to 6 g of antifoaming agent) was added to 4 kg of electrodeposition paint prepared in advance (POWERNICS 140, manufactured by Nippon Paint Co., Ltd.), and stirred at 400 rpm with a magnetic stirrer The mixture was allowed to dissolve for 1 hour to dissolve the defoamer in the coating. At this ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com