Inlaid diamond-cemented carbide strong wear resistant pick and producing technique thereof

A technology of impregnated diamond and cemented carbide teeth, applied in the field of picks, can solve the problems of protruding cemented carbide teeth, easy to wear and break, etc., and achieve the effect of simple and fast manufacturing process and improved wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

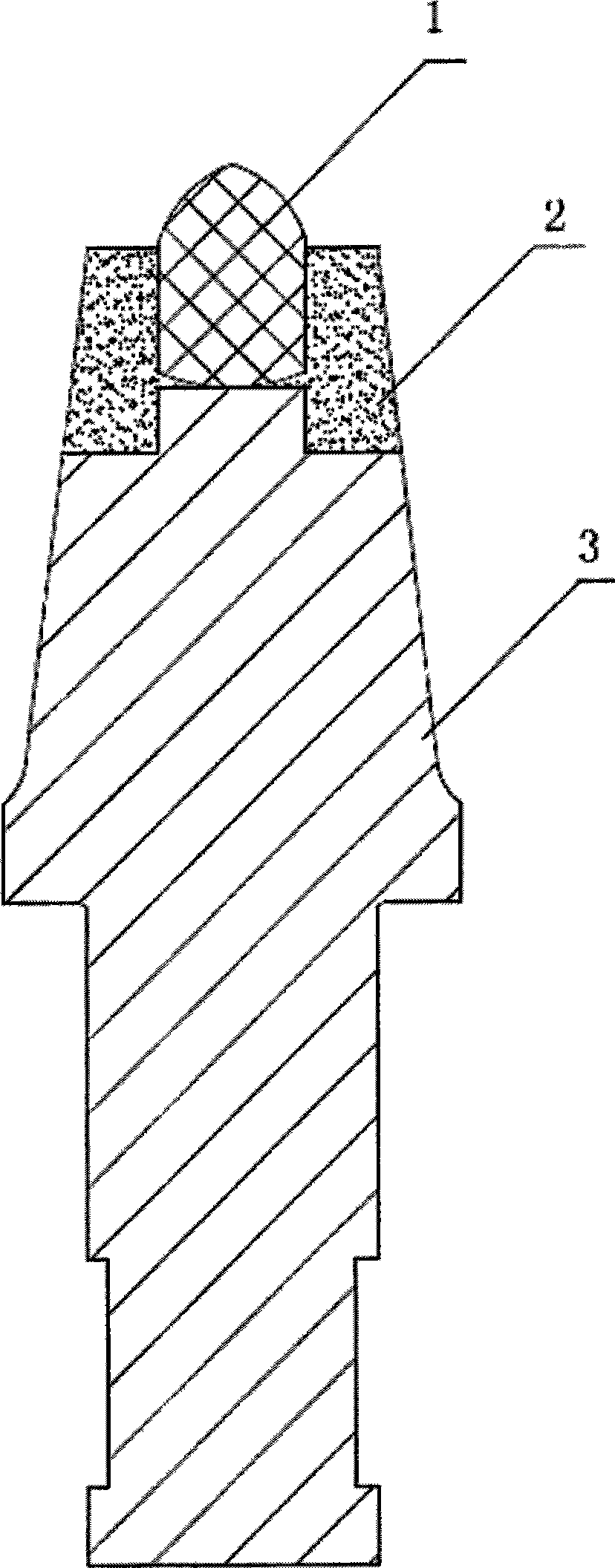

[0028] Such as figure 1 As shown, the steel tooth body 3, the tooth head 2 and the hard alloy tooth tip 1 are directly sintered into one body by powder metallurgy method and hot pressing process; the tooth head 2 contains ordinary carcass metal and non-metal powder , also added superabrasive diamond components, that is to say, the raw materials of the tooth head 2 include matrix powder and superabrasive, and the superabrasive uses diamond; the carcass powder contains cobalt powder, nickel powder, iron powder, copper powder, manganese Powder, tin powder, chromium powder and tungsten carbide powder, the particle diameter of the matrix powder is not more than 0.074mm, and the total weight of the five metal powders of cobalt powder, nickel powder, iron powder, manganese powder and chromium powder accounts for the total weight of the matrix powder. 10% to 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com