Method for absorption treatment of noxious exhaust gas by electrochemistry method

An electrochemical and harmful gas technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve problems such as poor effects and achieve the effect of increasing reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

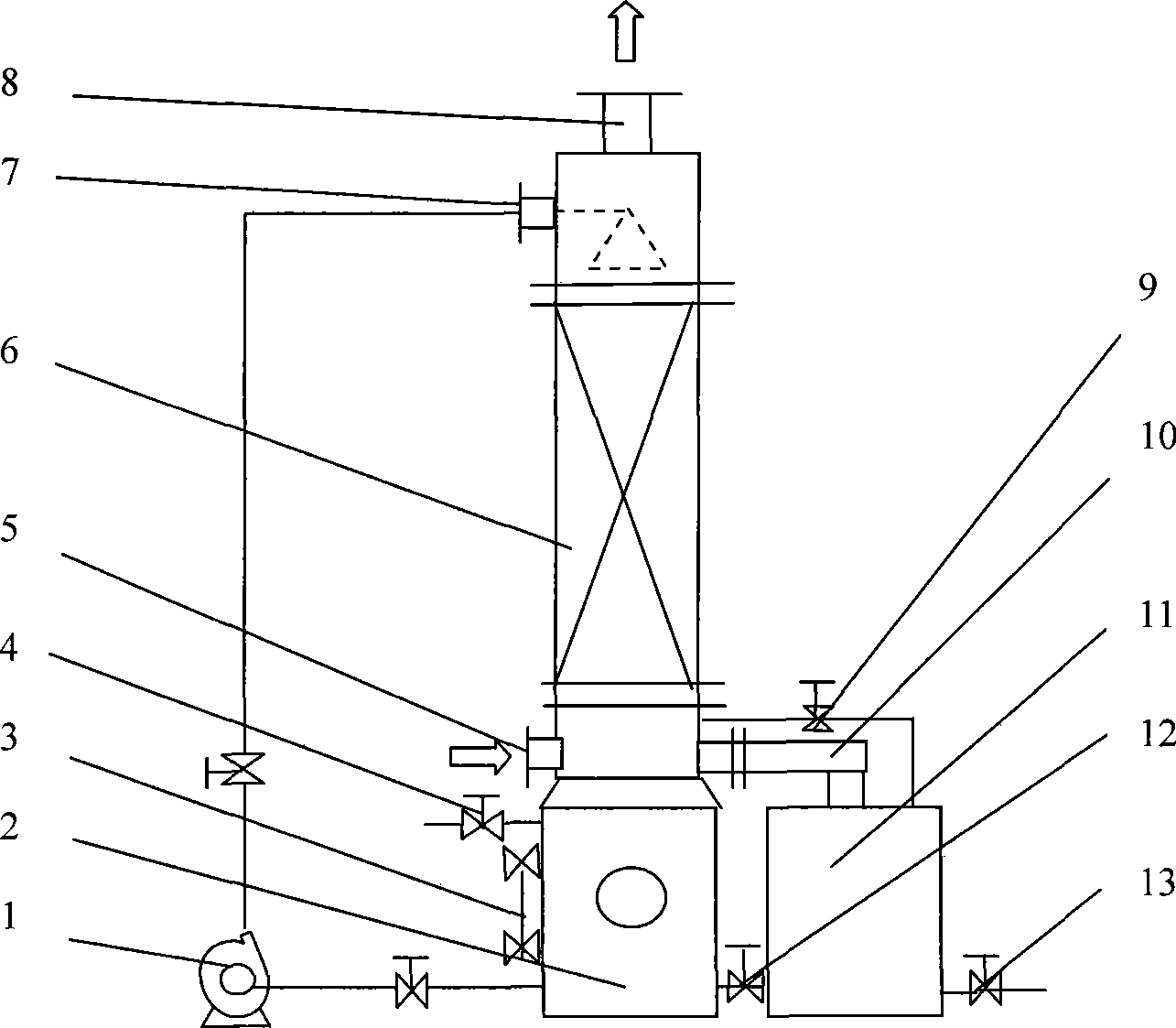

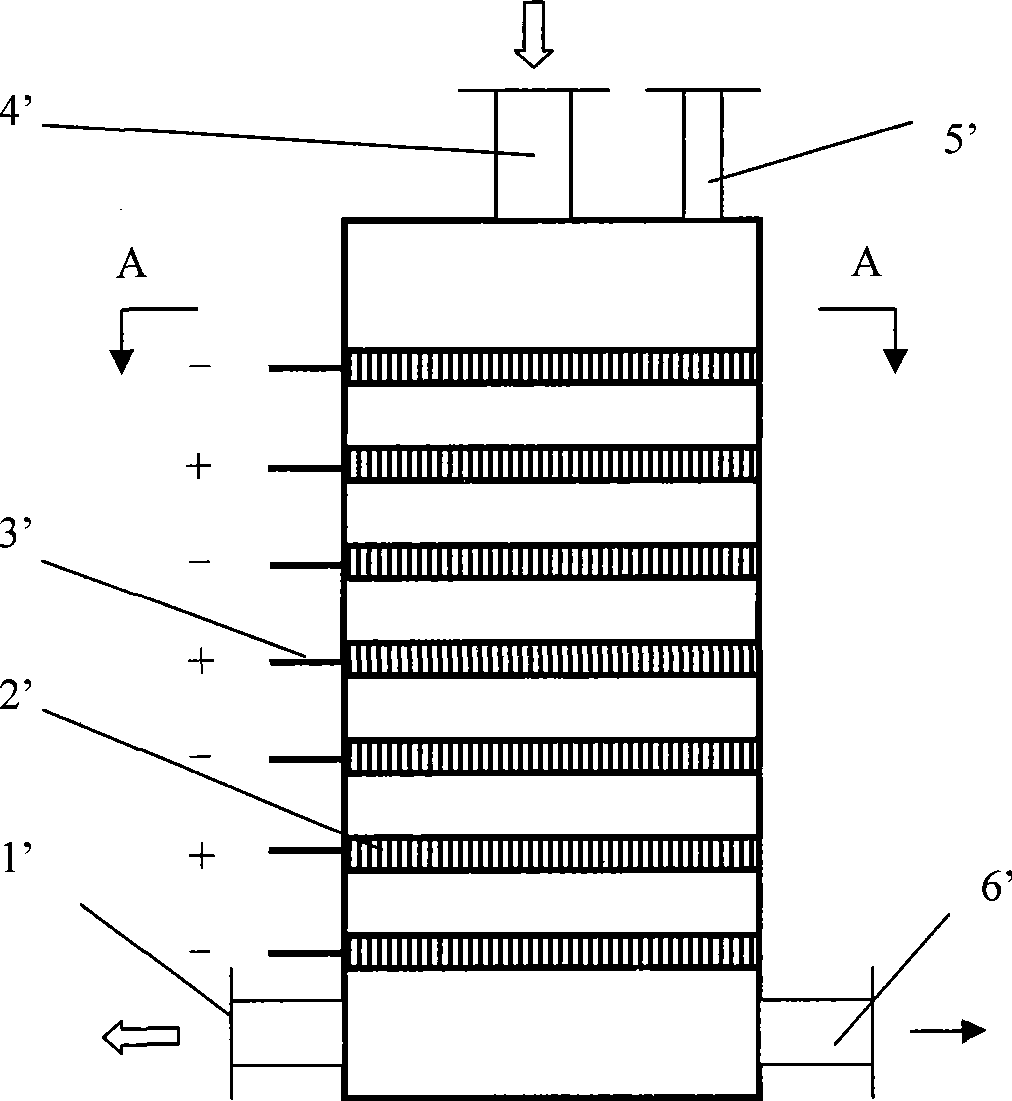

[0024] Embodiment 1: Experimental device system flow such as figure 1 As shown, the electrochemical reactor is shown in Figure 2. The structural size of the reactor is 400mm×400mm×1200mm, and it is composed of 6 sets of mesh electrode units superimposed, and the distance between the plates is 50mm. Mesh anode material is RuO 2 / Ti, the mesh cathode material is stainless steel. The size of the electrode mesh is 380mm×380mm, the thickness is 3mm, and the electrode mesh is 5mm×5mm. The absorption tower is a packed tower with a tower diameter of Φ500mm and a packing layer height of 2500mm. The simulated exhaust gas is air + gaseous harmful pollutants, which enters through the air inlet at the bottom of the absorption tower, passes through the absorption reaction zone, and is discharged from the upper part.

[0025] The experimental conditions are: power supply parameters: current 60A

[0026] Gas flow: 500m 3 / h, gas temperature: 25°C

[0027] Absorption circulation fluid f...

Embodiment 2

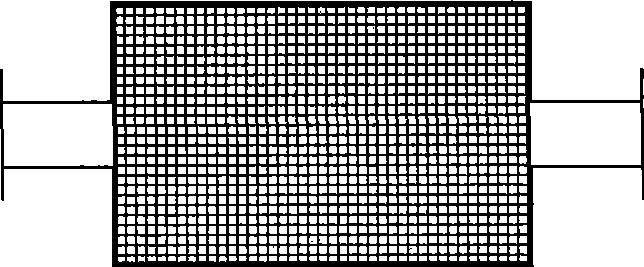

[0033] Embodiment 2: The electrochemical reactor is as shown in FIG. 3 . The structural size of the reactor is 400mm×400mm×1200mm, and it is composed of 2 sets of flat electrodes, each set of electrodes is composed of 6 pairs of units, separated by a fluid distributor between the two sets. The plate anode material is RuO 2 / Ti, the flat cathode material is stainless steel. The electrode size is 190mm×380mm, and the plate thickness is 3mm. The distance between the electrode plates is 50mm. Other conditions are the same as embodiment 1

[0034] The experimental conditions are: power supply parameters: pulse frequency 100Hz, current 100A

[0035] Gas flow: 500m 3 / h, gas temperature: 25°C

[0036] Circulation pump flow: 10m 3 / h.

[0037] Absorbing solution: 0.3% hydrochloric acid solution or a mixed solution of 0.5% sulfuric acid and 4% sodium sulfate or a mixed solution of 0.5% sulfuric acid and 0.1% hydrochloric acid.

[0038] The experimental results are shown in Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com