Copper foil with primer resin layer and laminate using the same

A technology of resin layer and primer, which is applied in the direction of synthetic resin layered products, primer, coating, etc., can solve the corrosion and oxidation of copper foil surface, the inability to improve the bonding strength, and the inability to improve the heat resistance and mechanical strength of the bonding strength. Satisfactory, etc., to achieve improved performance, reduced total etching costs, and no hardening shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] The present invention will be described more specifically by way of examples below, but the present invention is not limited to these examples.

[0060] The method of measuring the change of the surface of the copper foil in the copper foil with a primer resin layer and the adhesive strength of the copper clad laminate is as follows.

[0061] 1. Changes on the surface of copper foil

[0062] Regarding the change of the copper foil surface in the primer resin layer copper foil, the state of the copper foil surface immediately after forming the primer resin layer and the change of the copper foil surface one week later were visually observed.

[0063] 2. Adhesion strength between primer resin layer and copper foil in copper clad laminates

[0064] A 10 mm wide pattern was masked on the copper foil side of the copper clad laminate obtained in the example, and the copper foil except the masked part was dissolved to form a 10 mm wide copper foil pattern. Use an adhesive sh...

Synthetic example 1

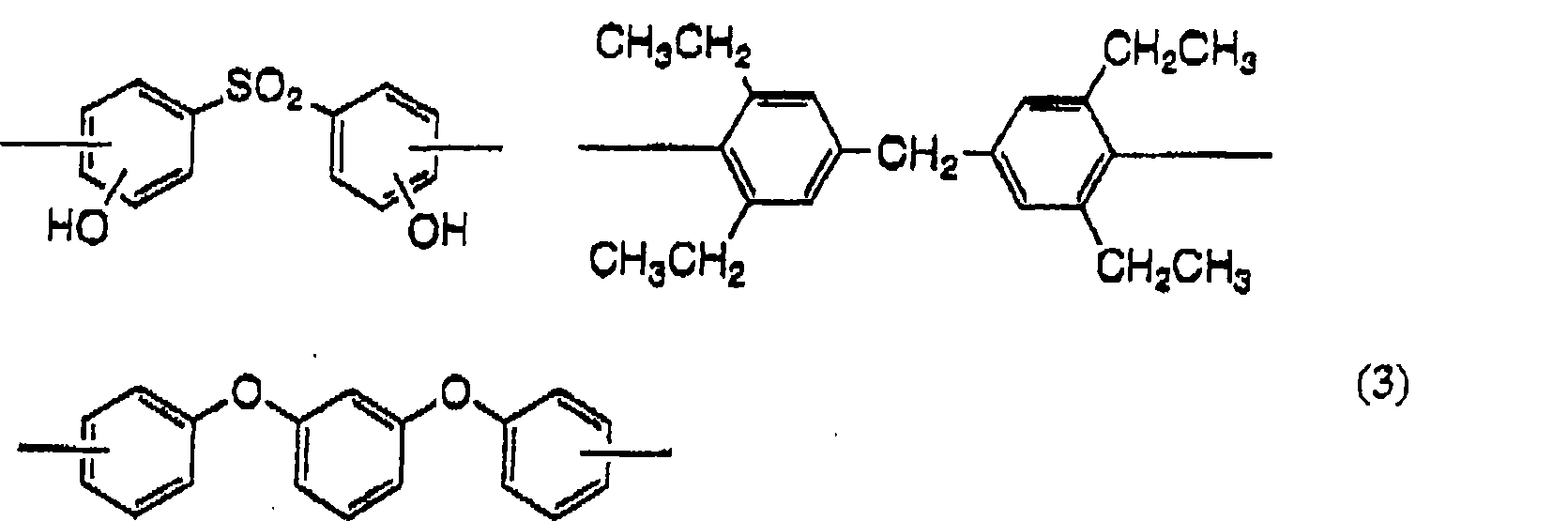

[0066] In a 300ml reactor equipped with a thermometer, reflux condenser, Dean-Stark device, powder inlet, nitrogen introduction device and stirring device, add 1,3-bis-(3-aminophenoxy)benzene as a diamine component (APB-N, manufactured by Mitsui Chemicals Co., Ltd., molecular weight 292.34, hereinafter only referred to as APB-N) 24.84g (0.085 moles), while feeding dry nitrogen, add 38.42g of methyl benzoate as a solvent, and at 60 °C and stirred for 30 minutes. Then, 26.88 g (0.087 mol) of 4,4'-oxydiphthalic anhydride (ODPA, manufactured by MANAC, molecular weight 310.22, hereinafter simply referred to as ODPA) as a tetracarboxylic dianhydride component was added as a solvent 57.63 g of γ-butyrolactone, 0.868 g of γ-valerolactone as a catalyst, 1.371 g of pyridine, and 22.2 g of toluene as a dehydrating agent. The inside of the reactor was heated to 180° C., and the heating ring closure reaction was performed for 6 hours while removing water generated in the fractionation tub...

Synthetic example 2

[0071]In a 500ml reactor equipped with a thermometer, reflux condenser, Dean-Stark device, powder inlet, nitrogen inlet and stirring device, add 1,3-bis-(3-aminophenoxy)benzene as a diamine component (APB-N) 14.67 g (0.050 mol), 3,3'-diamino-4,4'-dihydroxydiphenyl sulfone (ABPS, manufactured by Nippon Kayaku Co., Ltd., molecular weight 280.3) 26.13 g (0.093 mol) , while blowing dry nitrogen gas, 64.02 g of methyl benzoate was added as a solvent, and stirred at 60° C. for 30 minutes. Then, 45.38 g (0.146 mol) of 4,4'-oxydiphthalic anhydride (ODPA) as a tetracarboxylic dianhydride component, 96.03 g of γ-butyrolactone as a solvent, and γ-butyrolactone as a catalyst were added thereto. - 1.465 g of valerolactone, 2.314 g of pyridine, and 32.5 g of toluene as a dehydrating agent. The inside of the reactor was heated to 180° C., and the heating ring closure reaction was performed for 6 hours while removing water generated in the fractionation tube. After the imidization reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com