Process for preparing multiphase catalysts for ester exchange synthesizing diphenyl carbonate

A technology of diphenyl carbonate and heterogeneous catalysts, which is applied in the direction of organic carbonate preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of separation, recovery and environmental pollution, and achieve low cost and low raw material price The effect of being cheap and easy to obtain and the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First, 100-250 mesh SiO 2 Activation at 600°C for 6 hours, vacuum treatment for 8 hours, vacuum degree -0.095~-0.08MPa, weigh 2.4g of it in 80ml of anhydrous ethanol solution containing titanocene dichloride, TiO 2 with SiO 2 The molar ratio is 1:20, triethylamine is added under the protection of nitrogen, the molar ratio of triethylamine to titanocene dichloride is 1, reflux dipping for 8h, filtering, washing, drying overnight at 100-120°C, and then Calcined at 600°C for 6h to obtain the catalyst.

[0023] Embodiment 2 carries out the transesterification reaction of dimethyl carbonate and phenol with the catalyst prepared in embodiment 1

[0024] (1) in the there-necked flask that is connected with air guide tube and thermometer, constant pressure dropping funnel and rectifying column, add the catalyst 1.0 gram of embodiment 1;

[0025] (2) under feeding nitrogen, add 15 grams of phenol;

[0026] (3) When heated to 178° C., start to add dimethyl carbonate (DMC) dro...

Embodiment 3

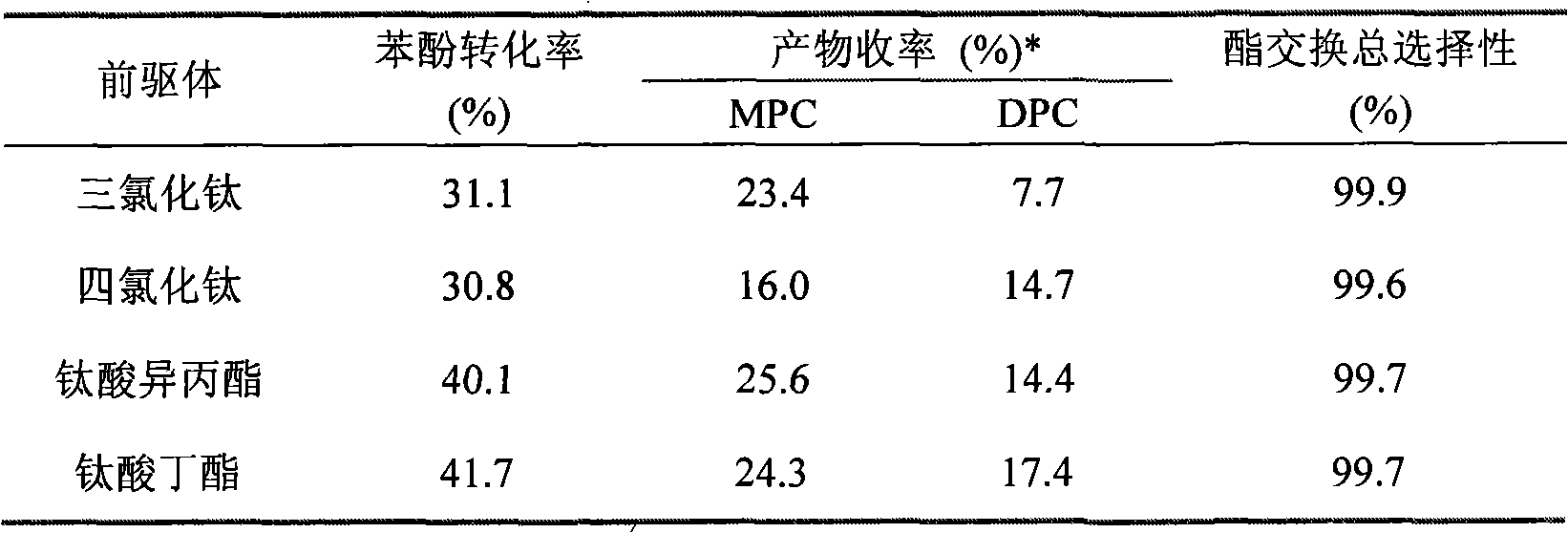

[0028] The preparation step of embodiment 3 catalyst is the same as embodiment 1, but changes TiO 2 Precursors, as shown in Table 1. Carry out the transesterification reaction of dimethyl carbonate and phenol with the prepared catalyst, the reaction conditions are the same as in Example 2, and the activity results are shown in Table 1.

[0029] Table 1 Different TiO 2 Effect of Precursors on Catalyst Activity

[0030]

[0031] * MPC-methylphenyl carbonate, DPC-diphenyl carbonate

Embodiment 4

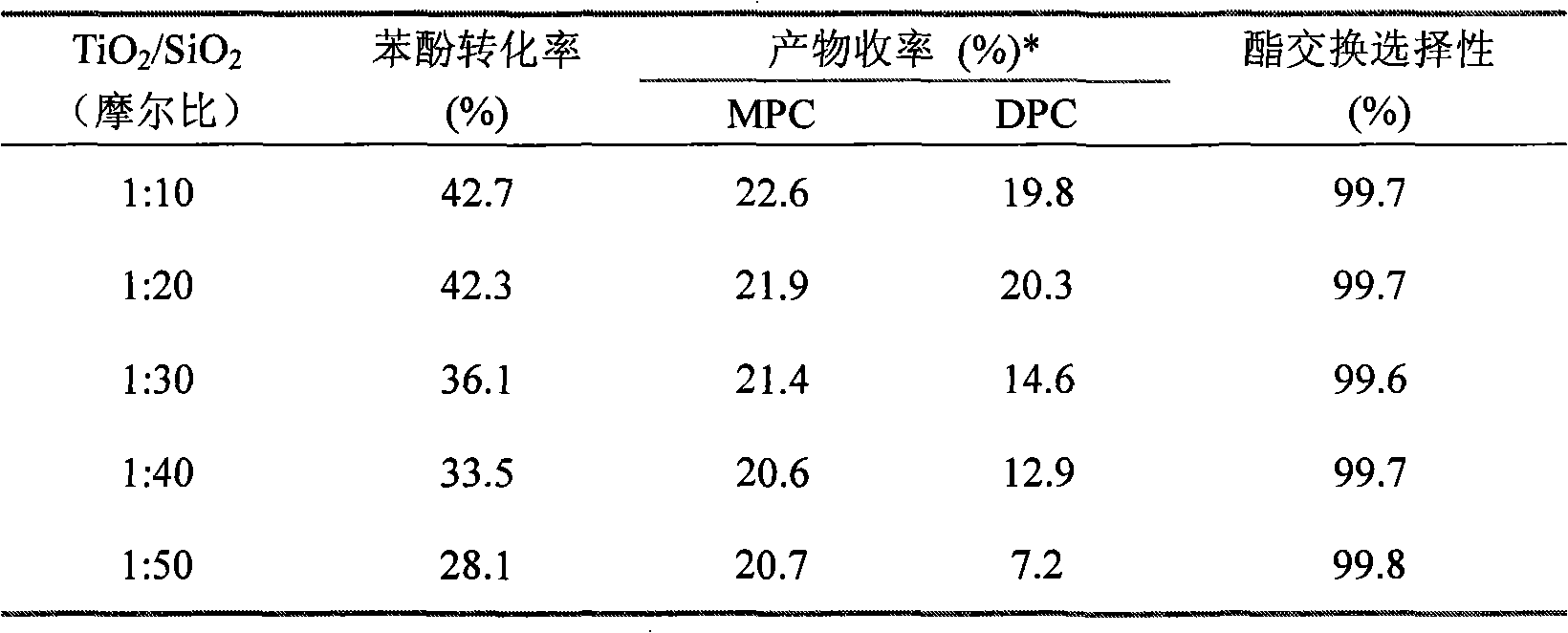

[0033] The preparation step of catalyst is the same as embodiment 1, but changes TiO 2 with SiO 2 The molar ratio is shown in Table 2. The prepared catalyst was used to carry out the transesterification reaction of dimethyl carbonate and phenol, the reaction conditions were the same as in Example 2, and the activity results were shown in Table 2.

[0034] Table 2 Different TiO 2 / SiO 2 The effect of molar ratio on catalyst activity

[0035]

[0036] * MPC-methylphenyl carbonate, DPC-diphenyl carbonate

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com