Method for preparing rare-earth ultra-steady Y molecular sieve

A technology of molecular sieves and rare earths, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor coke selectivity, serious damage to molecular sieve crystal integrity, and uncontrolled unit cell constants. Achieving high crystal integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 360ml water glass (SiO 2 =250g / L, modulus 3.2, Shandong Aluminum Plant) and 244ml high alkalinity sodium metaaluminate (Al 2 o 3 =40g / L, Na 2 (O=287g / L, same as above) and mix evenly, age at room temperature for 18 hours, add 100ml of deionized water, and use it as a guiding agent after stirring.

[0033] 3672ml water glass and 708ml above-mentioned directing agent, and 1164ml aluminum sulfate (Al 2 o 3 =90g / L, same as above) and 891ml low alkalinity sodium metaaluminate (Al 2 o 3 =100g / L, Na 2 (O=150g / L, same as above) mixed and stirred, adjust slurry pH to 13.0 with 10% by weight of dilute sulfuric acid (prepared by chemical reagents, Beijing Reagent Chemical Factory) and stir evenly, put into stainless steel reactor and crystallize at 100°C for 28 hours , filter and wash.

[0034] Take 100 grams of the above-mentioned molecular sieve dry basis, exchange it at 90° C. for 1 hour with 4% ammonium sulfate solution (prepared by chemical reagents, Beijing Reagent C...

Embodiment 2

[0049] 666ml of water glass and the directing agent in 109ml of embodiment 1, and 191ml of aluminum sulfate and 126ml of low alkalinity sodium metaaluminate are mixed and stirred, adjust slurry pH to 13.1 Stir evenly, put into a stainless steel reactor and crystallize at 95°C for 30 hours, filter and wash.

[0050] Take 100 grams of the above-mentioned molecular sieve dry basis, exchange it at 90° C. for 1 hour with 5% ammonium chloride solution (prepared by chemical reagents, Beijing Reagent Chemical Factory) at a liquid / solid ratio of 20:1, and dry it at 580° C. 1.5 hours -1 Calcined under the water vapor atmosphere for 2 hours, then exchanged with 5% ammonium chloride for 1 hour under the same conditions.

[0051] Molecular sieve calculated on a dry basis: Rare earth carbonate (Beijing Reagent Chemical Factory) 1: 0.02 feed ratio Molecular sieve and rare earth carbonate were mixed in a stirring mill with 2 mm diameter zirconium beads of 5 times the weight and ground for 2 ...

Embodiment 3

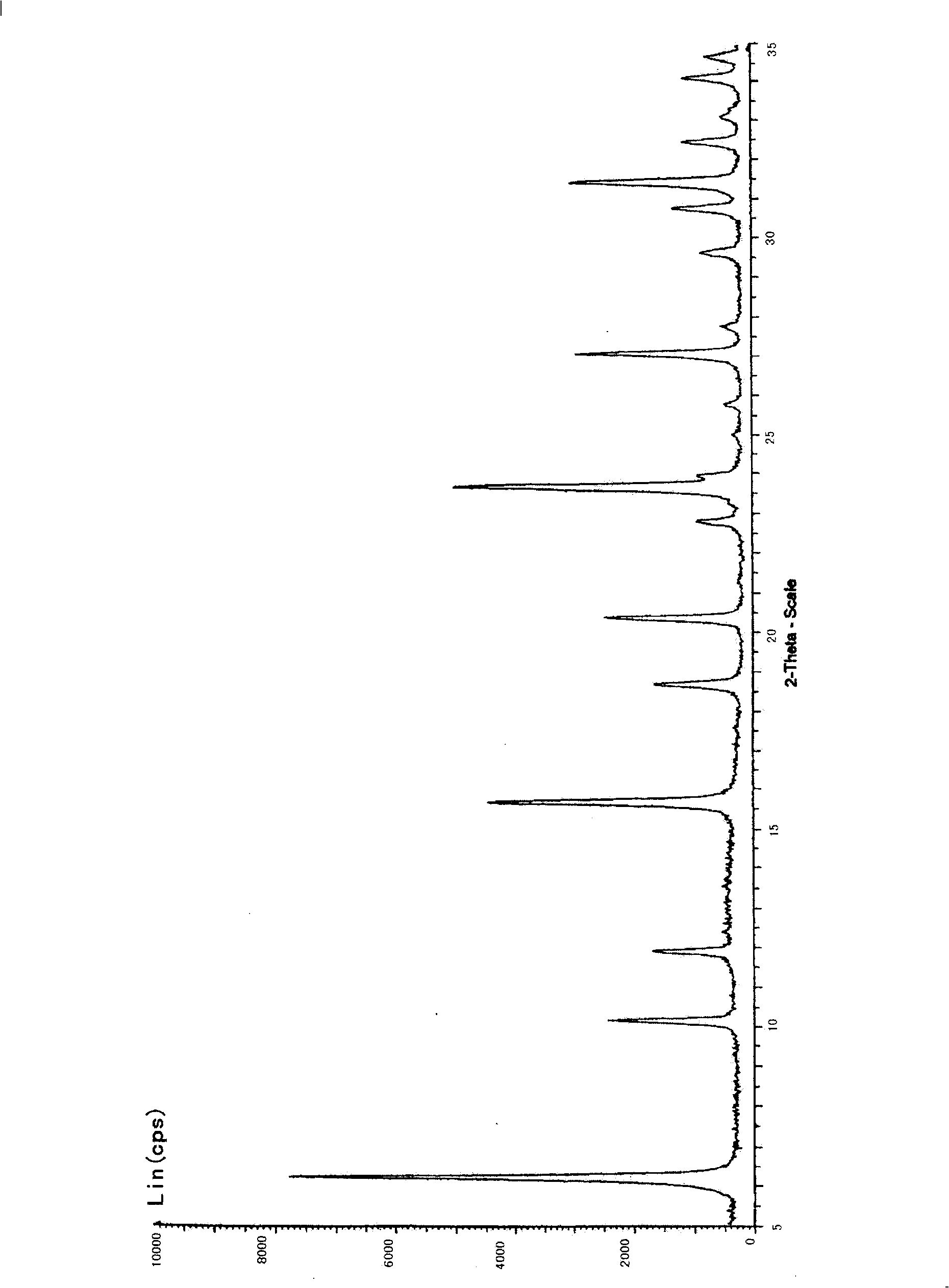

[0062] Take 100 grams of NaY molecular sieve synthesized in Example 1, mix in a beaker according to molecular sieve:ammonium nitrate:water=1:0.8:20 and react at 90°C for 1 hour. Filter and dry at 550°C for 1 hour at space velocity -1 Roasting under water vapor under the water vapor atmosphere for 2 hours, then exchange and roast under the same conditions to form a two-cross-two-baking molecular sieve, molecular sieve calculated on a dry basis: rare earth phosphate (same as Example 1) 1: 0.03 feed ratio of molecular sieve Mix 5 times the weight of zirconium beads with a diameter of 1.5mm in a stirring mill with rare earth phosphate and grind for 1.5 hours at a speed of 80 rpm, and sieve the zirconium beads. The X-ray diffraction phase diagram of the product and figure 1Similar, unit cell constant 2.455nm, BET surface area 630m 2 / g.

[0063] Catalyst microspheres were prepared in the same manner as in Example 1, and the coke / conversion ratio was 0.105 in the micro-reaction e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell constant | aaaaa | aaaaa |

| Bet surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com