A kind of iron-based powder catalyst for synthesizing ultrafine particle diamond

A technology of ultra-fine particles and iron-based powders, applied in the application of ultra-high pressure process, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of high cost and achieve low cost , low temperature, and the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

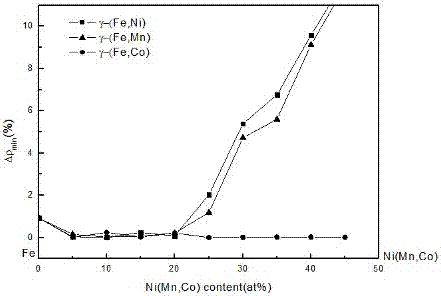

Image

Examples

Embodiment 1

[0020] In this embodiment, an iron-based powder catalyst for synthesizing ultrafine-grained diamonds comprises 25% by weight of Mn, 15% of Ni, 10% of Zn, and the balance is Fe.

[0021] During preparation, the raw materials are prepared according to the formula, and the prepared raw materials are put into an argon-protected intermediate frequency furnace for melting and refining. The powdered alloy was prepared by high-pressure gas atomization process. The powdered alloy is sieved, and the powdered alloy with a particle size of 400 meshes is selected as a product. The screened powdered alloy is placed in a hydrogen reduction furnace for reduction. The catalyst alloy powder and graphite powder are evenly mixed in a certain proportion, and after high temperature treatment, the diamond is synthesized. The proportion of synthetic diamond particles with a particle size of ≤400 mesh accounts for about 82%, with high crystal integrity and good transparency.

Embodiment 2

[0023] The composition and preparation method of the catalytic alloy are basically the same as those in Example 1, except that the powdered alloy with a particle size of 500 meshes is selected as the product to synthesize diamond by sieving. The proportion of synthetic diamond particles with a particle size of ≤400 mesh accounts for about 85.3%, with high crystal integrity and good transparency.

Embodiment 3

[0025] Its preparation method is basically the same as Example 1, the difference is that, by weight percentage, the catalyst alloy ingredients are: Mn 30%, Ni 10%, Zn 8%, the balance is Fe, and the particle size selected by sieving is 600 mesh powder Shaped alloy is the product of synthetic diamond. The proportion of synthetic diamond particles with a particle size of ≤400 mesh accounts for about 87.6%, with high crystal integrity and good transparency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com