Bamboo wood dissolving pulp manufacturing process

A manufacturing process and technology for dissolving pulp, applied in papermaking, textile and papermaking, pulping with inorganic alkali, etc. The effect of reduced liquid volume and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

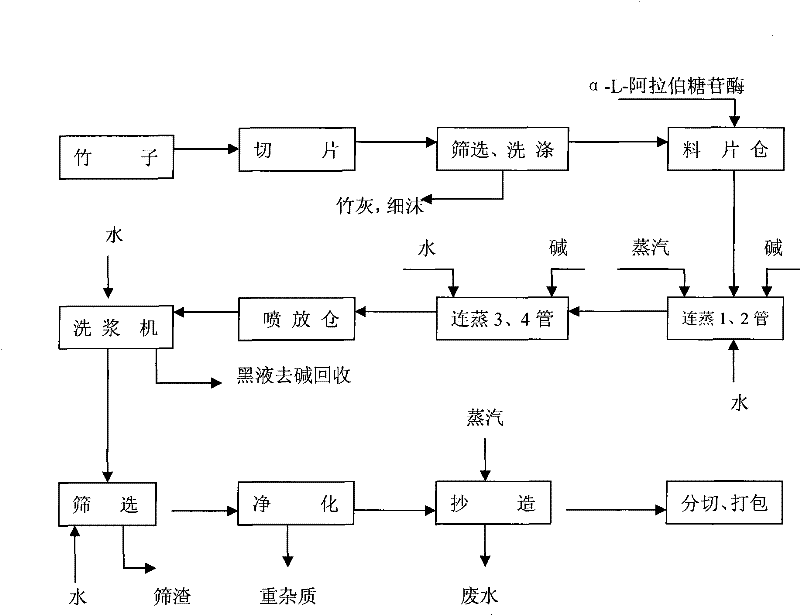

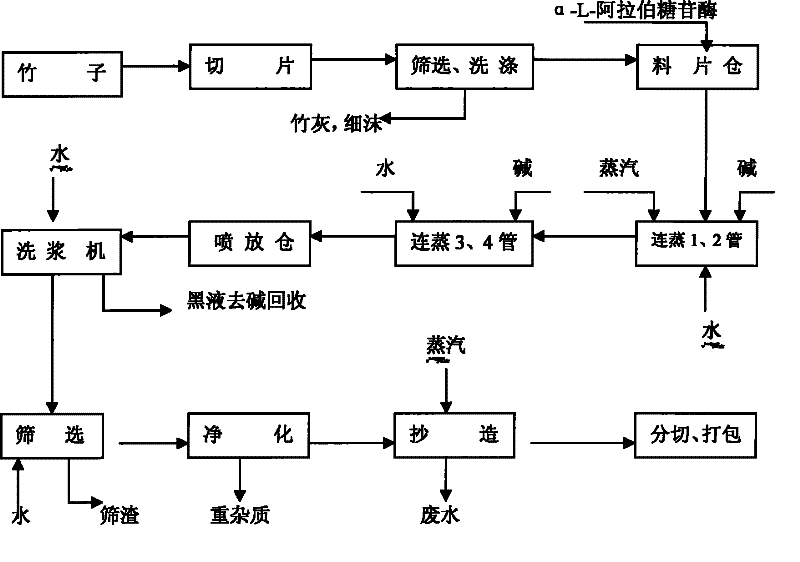

[0018] Such as figure 1 Shown, a kind of manufacture technique of bamboo dissolving pulp specifically comprises the following processing steps:

[0019] A. The original bamboo is cut into 2.5-4cm long bamboo slices by a disc slicer (or a roller slicer), and the cutting length rate is above 95, and the super long bamboo slices are selected. The qualified bamboo slices after cutting are washed with water to remove the fine impurities on the bamboo slices. At the same time, it can also adjust the moisture content of the bamboo slices evenly.

[0020] B. The washed bamboo slices are transported to the silo by the belt conveyor, and the aqueous solution containing α-L-arabinosidase is sprayed with a spray pipe before falling into the silo to pre-soak the bamboo slices in the silo to reduce the Decomposition of arabinose in bamboo chips. The conditions are as follows: enzyme preparation 180-200IU / g; addition amount 200 grams per ton of bamboo chips; pH value less than 4.6; temper...

Embodiment 2

[0034] A kind of manufacturing process of bamboo dissolving pulp, this process is to make natural color pulp board or pulp after bamboo is cut short, washed, pre-soaked, continuous cooking, and described pre-soaking is under 60 ℃, adopts pH value 200IU / g of the α-L-arabinosidase preparation of 4.0 is used as a presoaking agent, and the bamboo chips are presoaked for 20 minutes, and the addition of the α-L-arabinosidase preparation is 200 per ton of bamboo chips gram, the continuous cooking is to adopt the horizontal tube type continuous cooking device, adding the sulfate cooking liquid with large liquid ratio and large alkali amount in time intervals to continuously cook the pre-soaked bamboo for 300 minutes, once into pulp, the sulfate cooking liquid Contains NaOH and Na 2 S, the total amount of alkali used is 30% in terms of NaOH, and the degree of sulfide is 20%.

Embodiment 3

[0036] A kind of manufacturing process of bamboo dissolving pulp, this process is to make natural color pulp board or pulp after bamboo is cut short, washed, pre-soaked, continuous steaming, and described pre-soaking is under 40 ℃, adopts pH value Make presoaking agent for 3.8 α-L-arabinosidase preparation 180IU / g, carry out presoaking treatment to bamboo chip, treatment time is 60 minutes, the addition amount of α-L-arabinosidase is 200 grams per ton of bamboo chip , the continuous cooking is to use a horizontal tube type continuous cooking device, adding a large liquid ratio and a large amount of sulfate cooking liquid in different periods of time to continuously cook the pre-soaked bamboo for 400 minutes, once into pulp, the sulfate cooking liquid contains NaOH and Na 2 S, the total amount of alkali used is 42% in terms of NaOH, and the degree of sulfidation is 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com