Method for preparing porous alumina ceramic supporting body with sol as additive

A porous alumina and support technology is applied in the field of preparing porous Al2O3 ceramic supports, which can solve the problems of reduced acid and alkali resistance and high temperature resistance, easy to form agglomeration, difficult to disperse uniformly, etc., so as to shorten the production cycle and solve the problem of cracking. problem, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] One, the preparation method of aluminum sol:

[0030] Aluminum sol A: The raw material is aluminum chloride hexahydrate AlCl 3 ·6H 2 O, aluminum powder, hydrochloric acid. AlCl 3 ·6H 2 O is mixed with hydrochloric acid, and then gradually add aluminum powder to the above mixed solution, keep the temperature at 70-80°C, stir in a magnetic stirrer for 6 hours, and obtain a transparent colloidal liquid, that is, Al(OH) 4 The sol has a mass percent concentration of alumina of 20% and a particle diameter of 20-25 nanometers. The ratio of each reactant is that the molar ratio of hydrochloric acid to water is 0.21, and the pH value in the reaction process is 3-5, which can be adjusted with hydrochloric acid and ammonia water. The molar ratio of aluminum powder to aluminum chloride hexahydrate is 1.76.

[0031] Aluminum sol B: The raw materials are aluminum powder, nitric acid, and ammonia water. For the preparation of aluminum treatment solution, add 8g / L pure aluminum ...

Embodiment 1

[0041] Embodiment 1——aluminum sol A is used as auxiliary agent to prepare porous alumina support body:

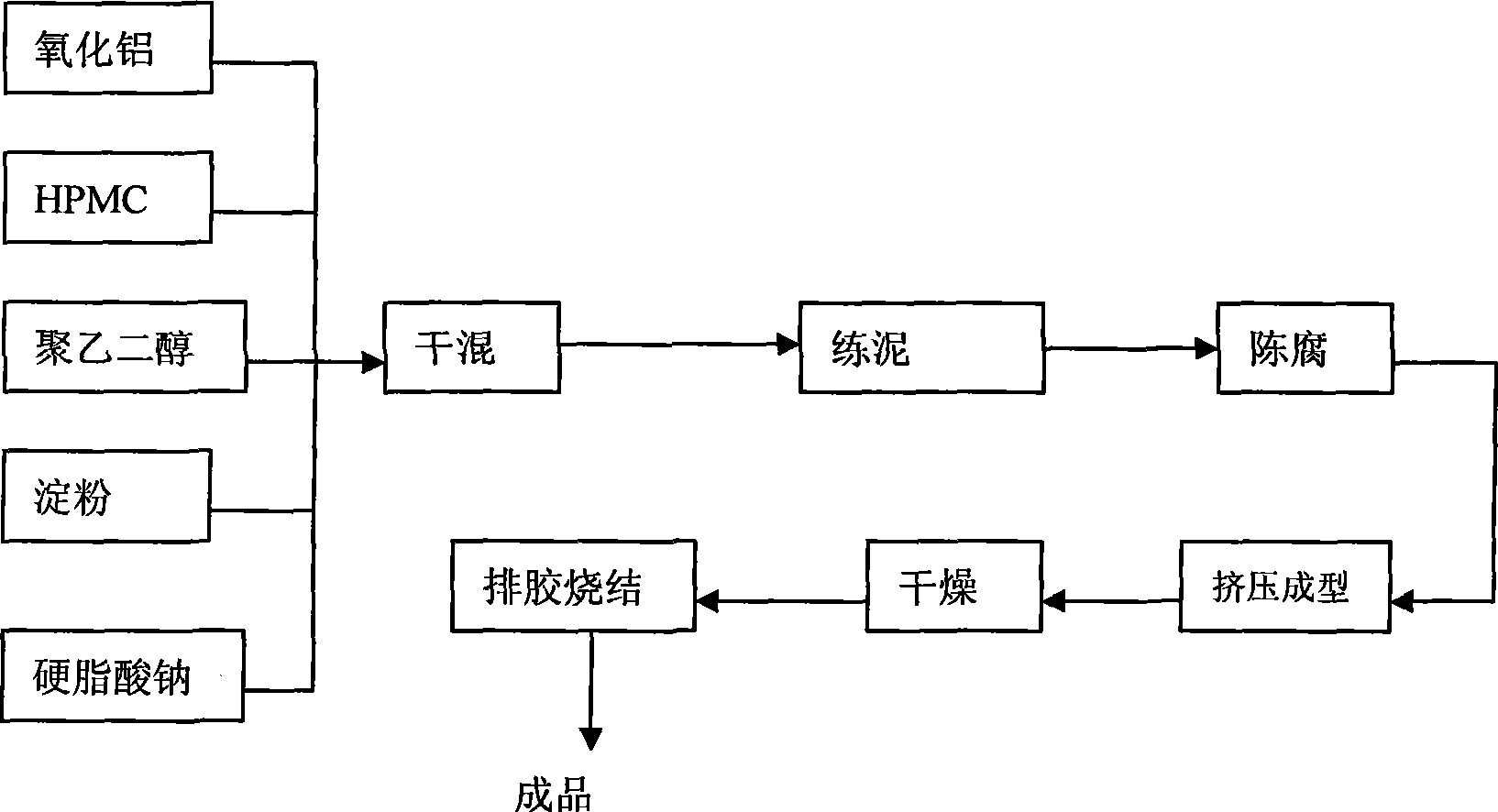

[0042] (1) 30 micron α-Al 2 o 3 The micropowder was weighed as an aggregate, and the α-Al 2 o 3 Based on the quality of micropowder, add binder HPMC6%, plasticizer polyethylene glycol (6000) 8%, dispersant sodium stearate 2%, pore-forming agent cornstarch 4%, do not add ball with planetary ball mill Dry mix for 3 hours.

[0043] (2) With aggregate α-Al 2 o 3 Based on the quality of the fine powder, add 10% aluminum sol A and water into the dry-mixed uniform mixture to make mud.

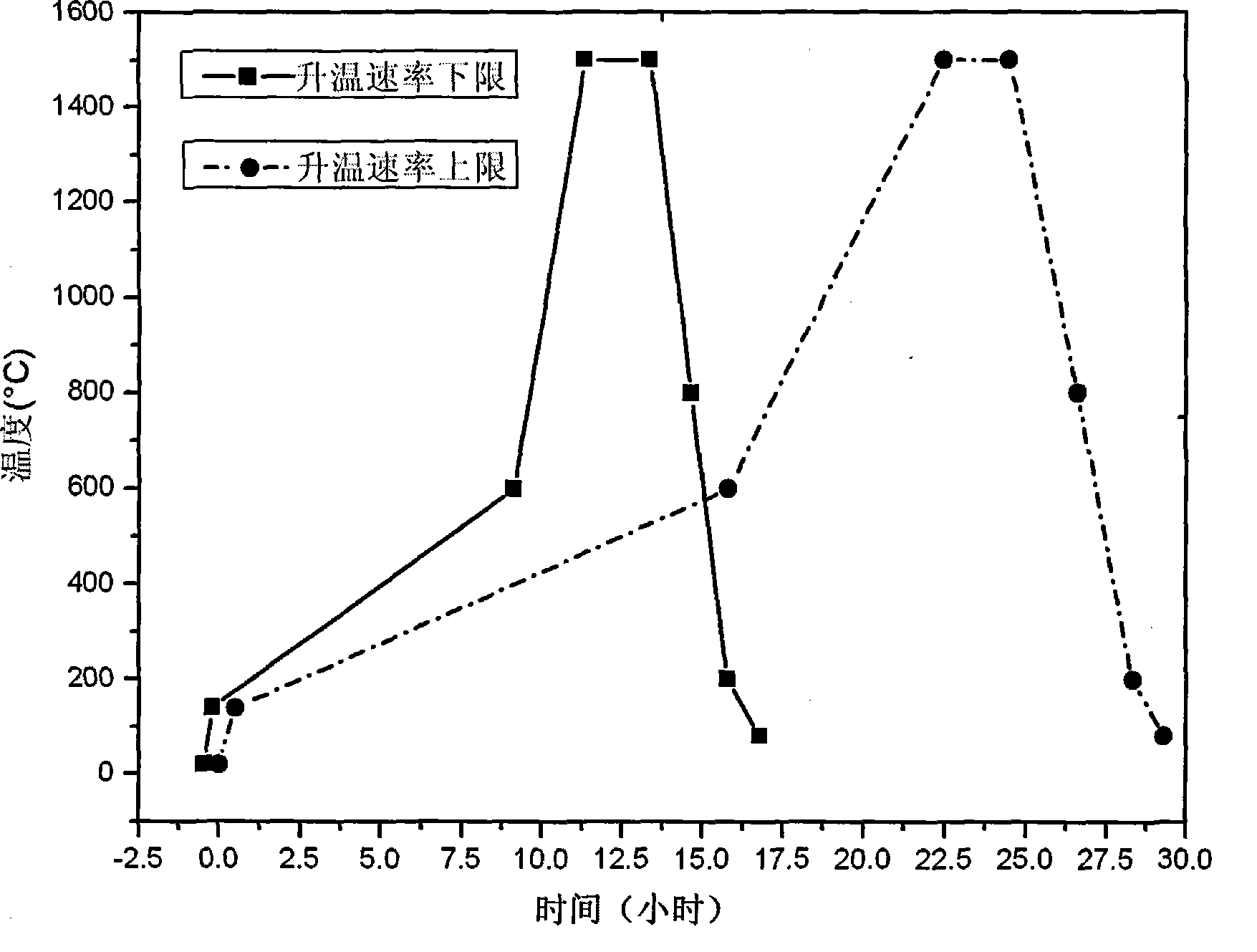

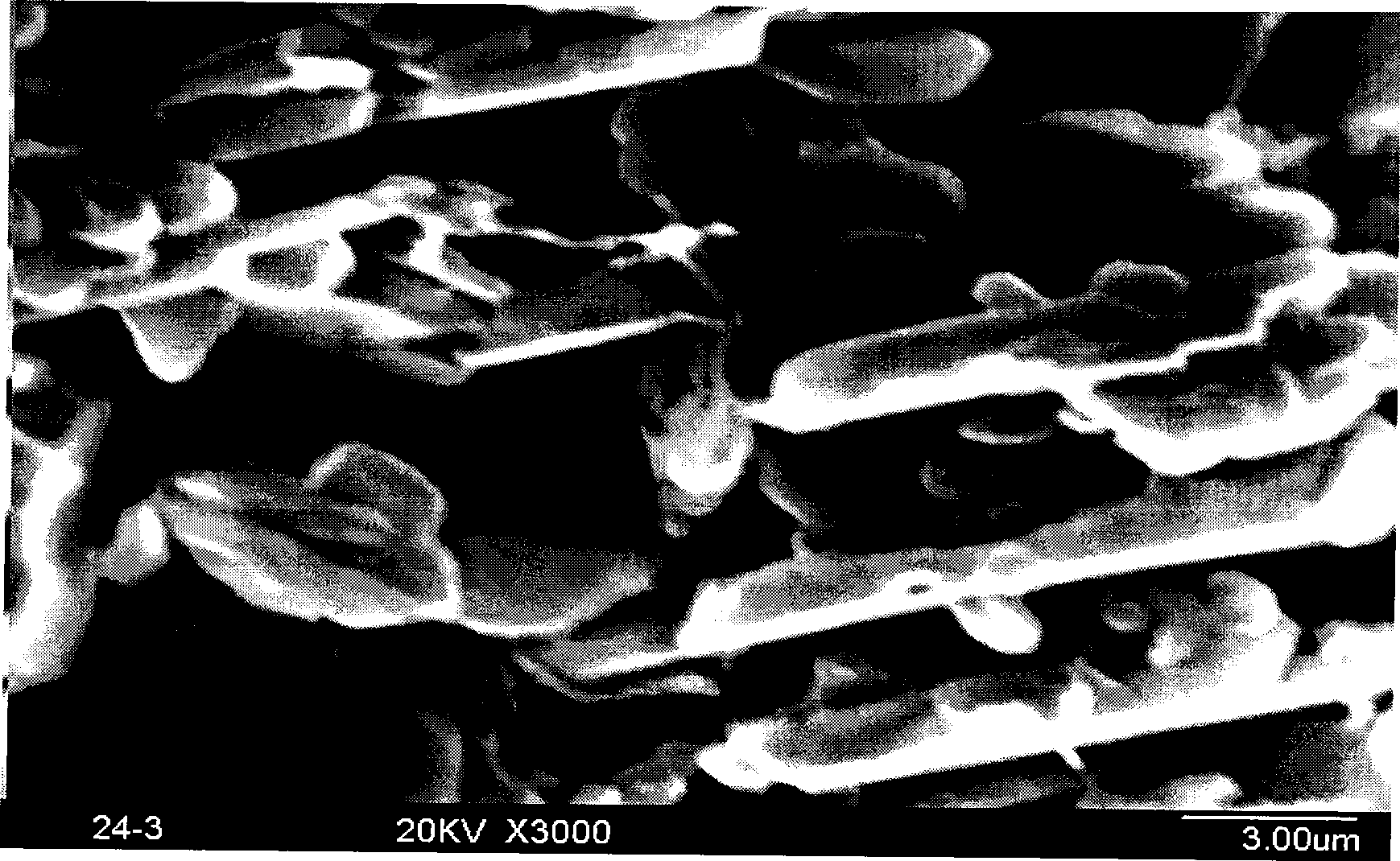

[0044] (3) Practicing the mud 5-10 times in a vacuum mud refining machine; encapsulating the mud material of the practiced mud in a package bag with a relative humidity of 80-90% and aging for 24 hours. Extrude 19 channels with a length of 100 cm (outer diameter 28-32 cm, channel diameter 3.5-4.0 cm, channel wall aperture 5-15 microns) and 50 cm 37 channels (outer diameter 40 cm, Channel di...

Embodiment 2

[0047] Embodiment 2——aluminum sol B is used as auxiliary agent to prepare porous alumina support body:

[0048] (1) 20 micron α-Al 2 o 3 The micropowder was weighed as an aggregate, and the α-Al 2 o 3 Based on the quality of micropowder, add binder HPMC8%, plasticizer polyethylene glycol (6000) 6%, dispersant sodium stearate 4%, pore-forming agent cornstarch 6%, do not add ball with planetary ball mill Dry mix for 2 hours.

[0049] (2) With aggregate α-Al 2 o 3Based on the quality of the fine powder, add 20% aluminum sol A and water into the dry-mixed uniform mixture to make mud.

[0050] (3) Practicing the mud 5-10 times in a vacuum mud refining machine; encapsulating the mud material of the practiced mud in a package bag with a relative humidity of 80-90% and aging for 24 hours. Extrude 19 channels with a length of 100 cm (outer diameter 28-32 cm, channel diameter 3.5-4.0 cm, channel wall aperture 5-15 microns) and 50 cm 37 channels (outer diameter 40 cm, Channel dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com