Sodium alanate and rare earth-nickel base alloy composite hydrogen storage material and preparation thereof

A technology of nickel-based alloy and sodium aluminum hydride, which is applied in the field of hydrogen storage materials, can solve the problems of being unable to adapt to large-scale application in industrial production, having no hydrogen storage capacity, and a complex preparation process, and achieves good low-temperature reversible hydrogen storage performance, suitable for Large-scale development and application, simple and practical effect of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

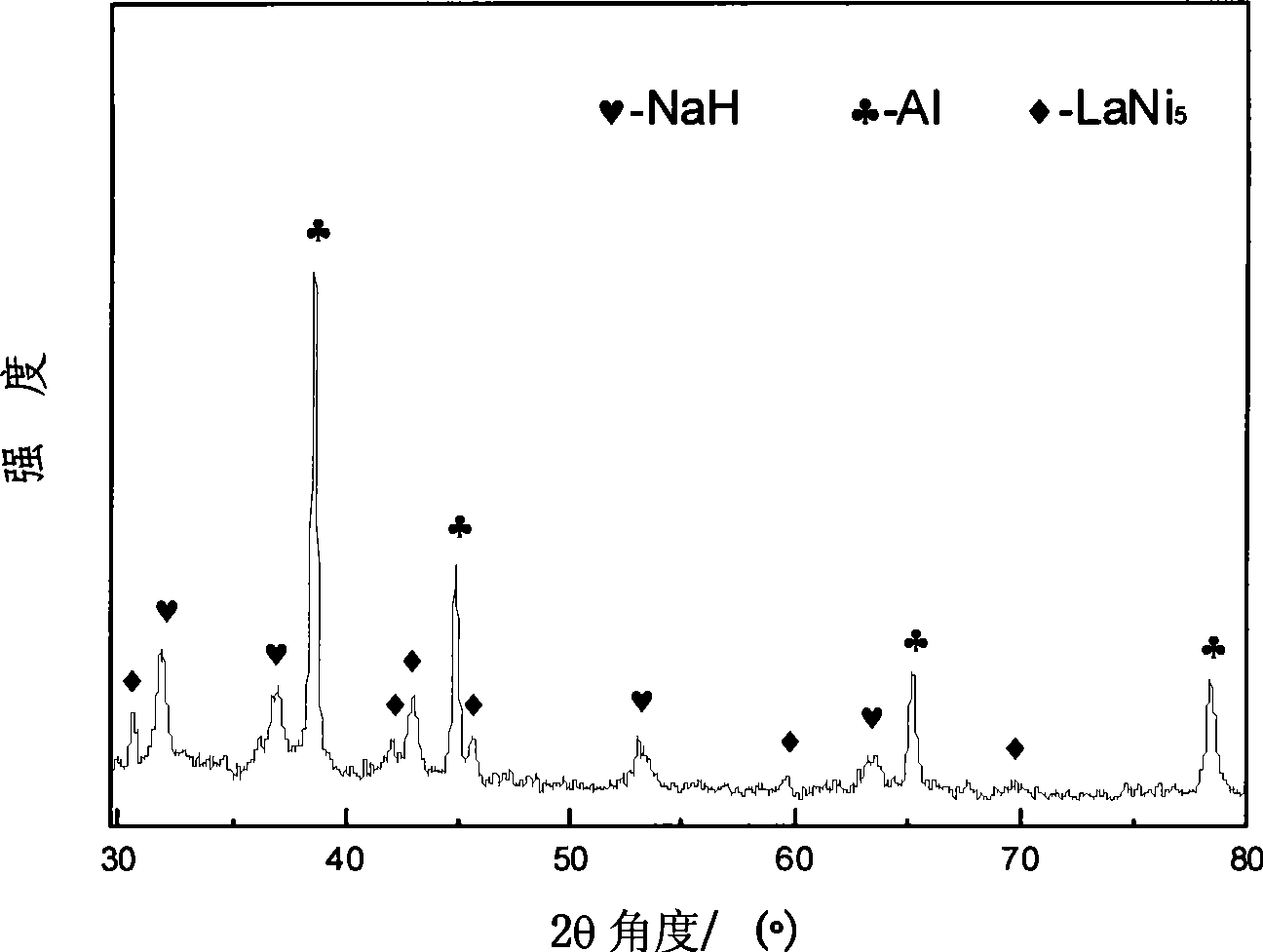

[0023] The NaH and Al raw materials used are commercial materials, the particle size of NaH powder is 74 μm, and the particle size of Al powder is 74 μm; according to the general chemical formula RENi of rare earth-nickel-based alloy 5 , select RE as La, which constitutes LaNi 5 Alloys according to LaNi 5 The chemical formula weighs La and Ni with a purity of more than 99%, and takes 40 grams of samples and repeatedly melts them in a high-frequency vacuum magnetic levitation furnace for 3 times to ensure that the alloy composition is uniform. 5 After the alloy is mechanically crushed to 74 μm, it is put into a ball mill tank filled with 0.5MPa hydrogen (purity ≥ 99.99%) for pre-ball milling for 10 hours to obtain LaNi 5 Alloy powder; then NaH and Al (NaH and Al molar ratio is 1:1, the same below) powder and the LaNi of above-mentioned pre-ball milling process 5 The powders were evenly mixed according to the mass percentage of 0.9:0.1, and then ball-milled for 5 hours under 0...

Embodiment 2

[0026] Raw materials used NaH, Al and cast LaNi 5 The parameters of the alloy are the same as in Example 1. The as-cast LaNi obtained by smelting 5 After the alloy is mechanically crushed to 74 μm, it is put into a ball mill tank filled with 1MPa hydrogen (purity ≥99.99%) and argon (purity ≥99.99%) for pre-ball milling for 15 hours to obtain LaNi 5 Alloy powder; then the NaH / Al powder was mixed with the above-mentioned LaNi pre-milled in different atmospheres 5 The powders were evenly mixed according to the mass percentage of 0.85:0.15, and then ball milled for 10 hours under 0.5MPa hydrogen (purity ≥ 99.99%) to finally prepare 85wt.% (Na / Al) + 15wt.% LaNi 5 Composite hydrogen storage materials.

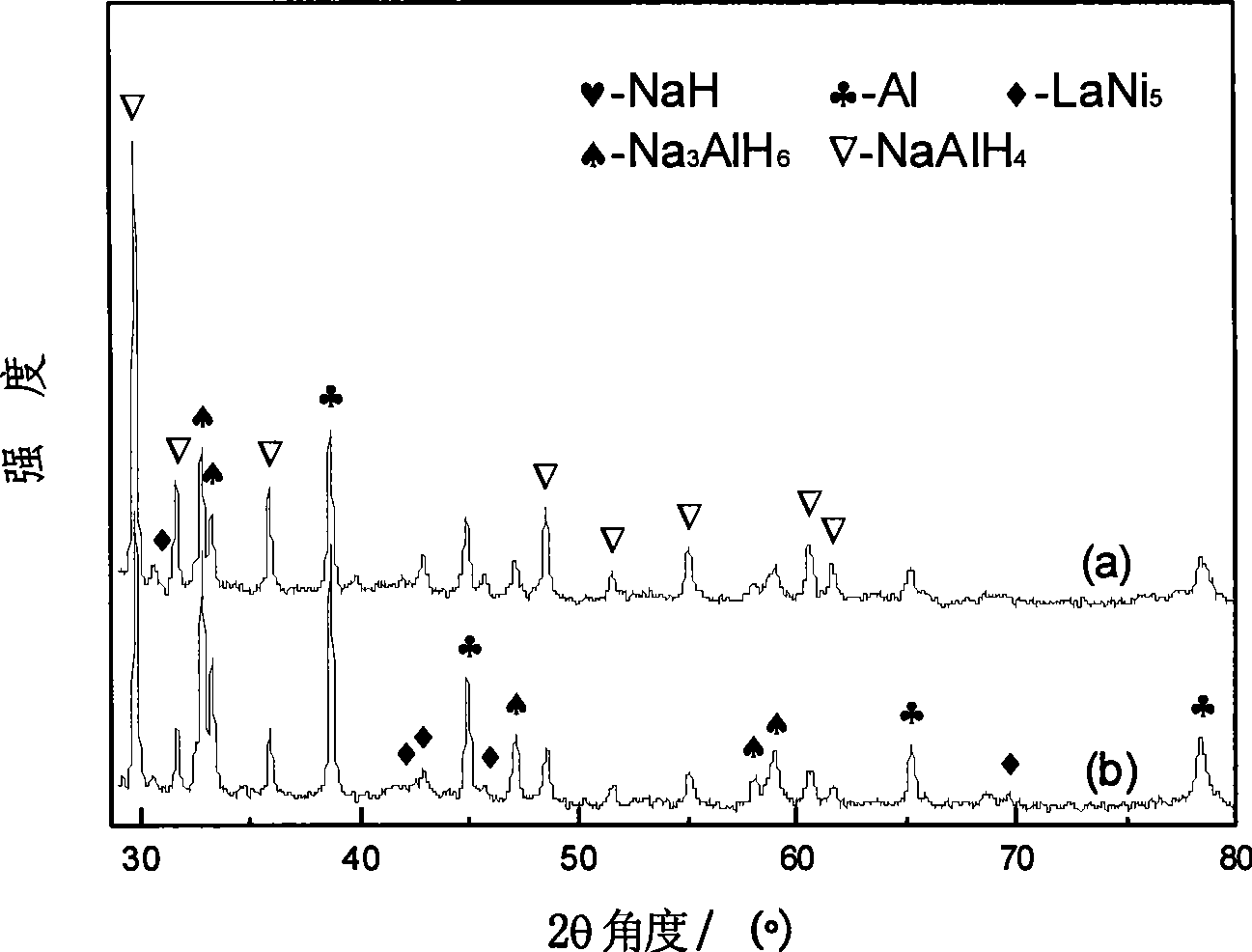

[0027] The hydrogen absorption and desorption properties of the prepared composite hydrogen storage materials were measured by "constant volume-pressure difference method". The hydrogen absorption and desorption cycle conditions are: hydrogen absorption at 100°C and 10MPa, hydrog...

Embodiment 3

[0030] Raw materials used NaH, Al and LaNi 5 The pre-milling parameters of the powder are the same as in Example 1. Mix NaH / Al powder with pre-milled LaNi 5 The powders were evenly mixed according to the mass percentage of 0.65:0.35, and then ball-milled for 1 hour under 0.5MPa hydrogen (purity ≥ 99.99%) to finally prepare 65wt.% (Na / Al) + 35wt.% LaNi 5 Composite hydrogen storage materials.

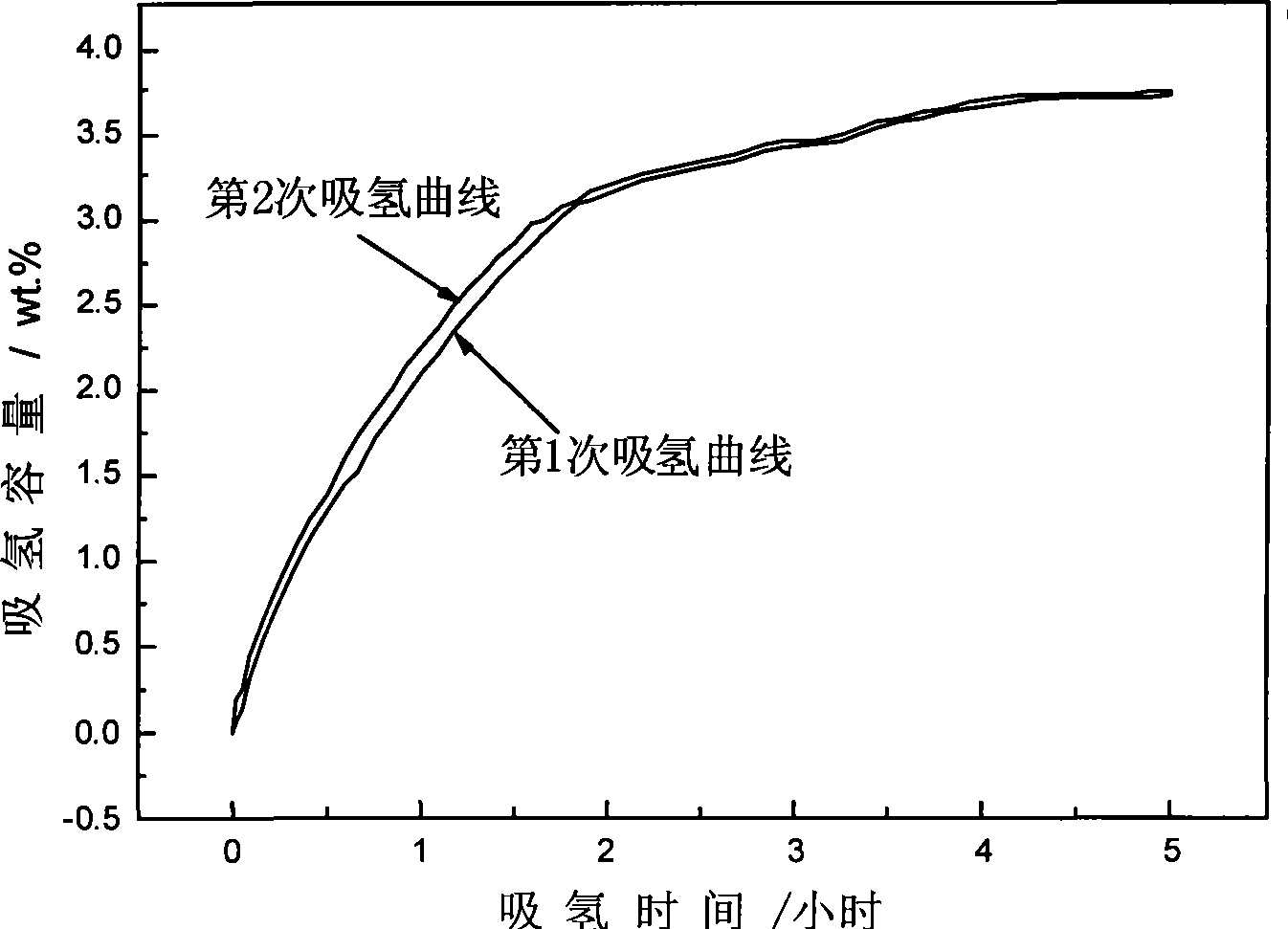

[0031] image 3 Is 65wt.% (Na / Al) + 35wt.% LaNi 5 Hydrogen absorption kinetics of the composites milled for 1 h at 100 °C. It can be seen that the hydrogen absorption capacity of the prepared composite hydrogen storage material at 100°C can reach more than 3.7wt.%, and the material can reach the maximum value in the first cycle, showing good activity performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com