Preparation method for high-specific-capacitance graphene/high-surface-activated carbon composite material

A composite material and high specific capacitance technology, which is applied in the manufacture of hybrid/electric double layer capacitors, chemical instruments and methods, hybrid capacitor electrodes, etc., can solve the problems of large-scale production, low specific surface area utilization, and poor product quality. Advanced problems, to overcome the effect of high production cost, low cost and high utilization rate of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

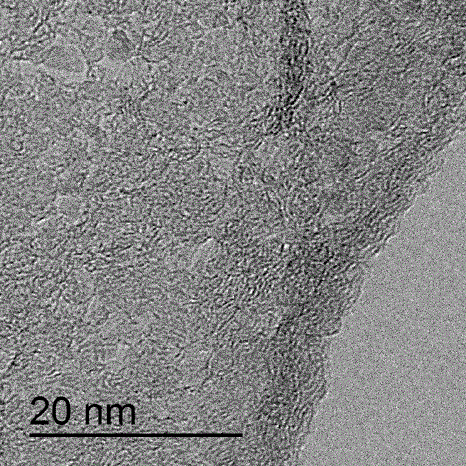

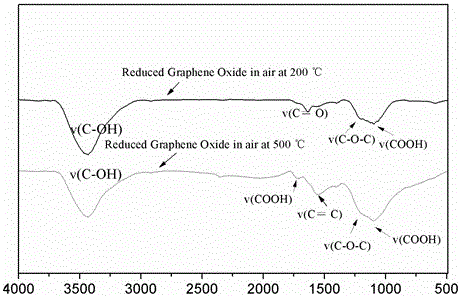

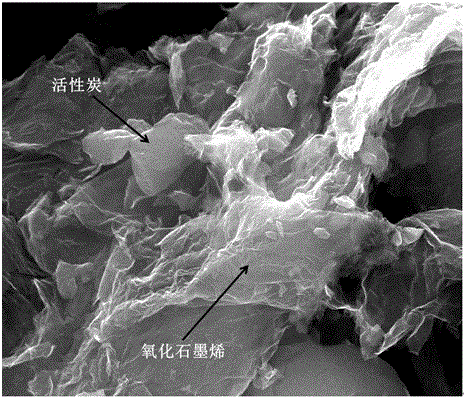

[0030] According to the present invention, the expanded graphite and potassium permanganate are ground and mixed evenly, and then stirred and reacted together with concentrated sulfuric acid and sodium nitrate in an ice bath at 0° C. for 24 hours, so that the oxidizing agent fully penetrates into the expanded graphite sheet. After the reaction is over, heat to 35°C in a water bath and keep for 2h, add deionized water to dilute, then gradually add 30wt% hydrogen peroxide according to the mass percentage of the total weight, and stir at 90-95°C for 15min. At this time, the solution was golden yellow, filtered while it was hot, added 5wt% HCl solution to wash several times, then repeatedly washed with deionized water until neutral, and continued to filter until no free SO was detected in the filtrate. 4 2- . Take the above-mentioned exfoliated graphite oxide in secondary deionized water, prepare the exfoliated graphite oxide slurry for subsequent use, then add high-surface activ...

Embodiment 2

[0033] According to the present invention, the expanded graphite and potassium permanganate are ground and mixed evenly, and then stirred and reacted together with concentrated sulfuric acid and sodium nitrate in an ice bath at 0° C. for 24 hours, so that the oxidizing agent fully penetrates into the expanded graphite sheet. After the reaction is over, heat to 35°C in a water bath and keep for 2h, add deionized water to dilute, then gradually add 30% hydrogen peroxide, and stir at 90-95°C for 15min. At this time, the solution was golden yellow, filtered while hot, added 5% HCl solution to wash several times, then repeatedly washed with deionized water until neutral, and continued to filter until no free SO was detected in the filtrate. 4 2- . Take the above-mentioned exfoliated graphite oxide in secondary deionized water to prepare an exfoliated graphite oxide slurry for future use. Then add high surface activated carbon (mass ratio of high surface activated carbon to exfoli...

Embodiment 3

[0036] According to the present invention, the expanded graphite and potassium permanganate are ground and mixed evenly, and then stirred and reacted together with concentrated sulfuric acid and sodium nitrate in an ice bath at 0° C. for 24 hours, so that the oxidizing agent fully penetrates into the expanded graphite sheet. After the reaction is over, heat to 35°C in a water bath and keep for 2h, add deionized water to dilute, then gradually add 30% hydrogen peroxide, and stir at 90-95°C for 15min. At this time, the solution was golden yellow, filtered while hot, added 5% HCl solution to wash several times, then repeatedly washed with deionized water until neutral, and continued to filter until no free SO was detected in the filtrate. 4 2- . Take the above-mentioned exfoliated graphite oxide in secondary deionized water to prepare an exfoliated graphite oxide slurry for future use. Then add high surface activated carbon (the mass ratio of high surface activated carbon to ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com