Electrochemical insertion/deinsertion magnesium ion electrode with high capacity and stable circulation and preparation method

An ionic electrode and electrochemical technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., to achieve high electrical and thermal conductivity, enhanced electrochemical performance, and strong mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of an electrochemical intercalation and extraction magnesium ion electrode with high capacity and stable cycle: 1) Preparation of graphite oxide nanosheets: disperse 1.25mmol (0.015g) of graphite powder into 20mL of concentrated sulfuric acid in an ice bath at 0°C , add 0.03g KMnO with stirring 4 , the added KMnO 4 The mass of graphite is 3 times that of graphite, stir for 30 minutes, the temperature rises to about 30°C, add 45ml of deionized water, stir for 20 minutes, add 10ml of 30% H 2 o 2 , stirred for 5 minutes, centrifuged, and repeatedly washed with a mass concentration of 5% HCl solution, deionized water and acetone to obtain graphite oxide nanosheets;

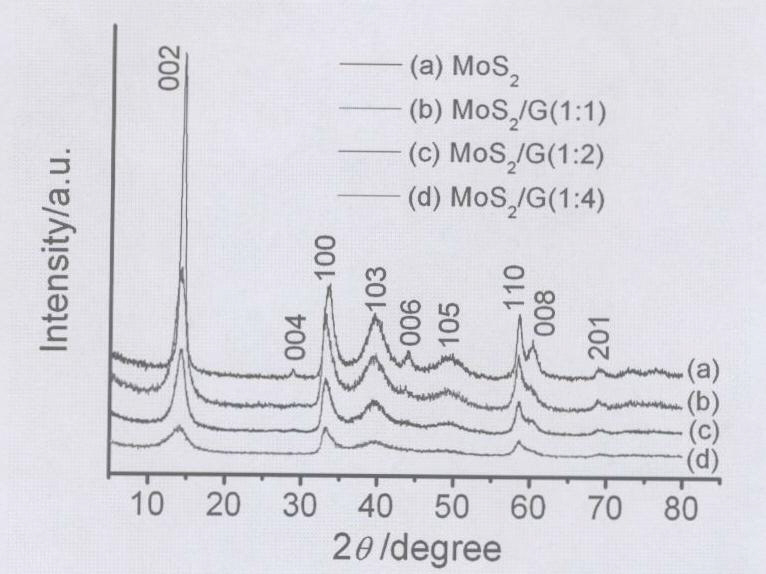

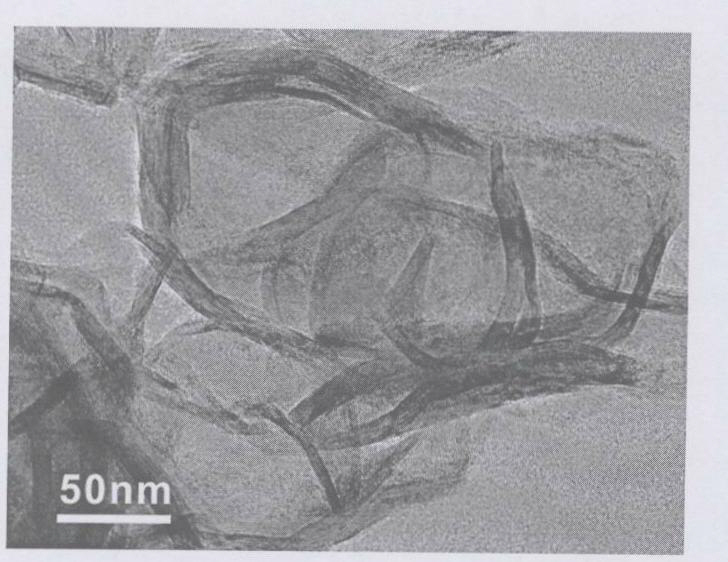

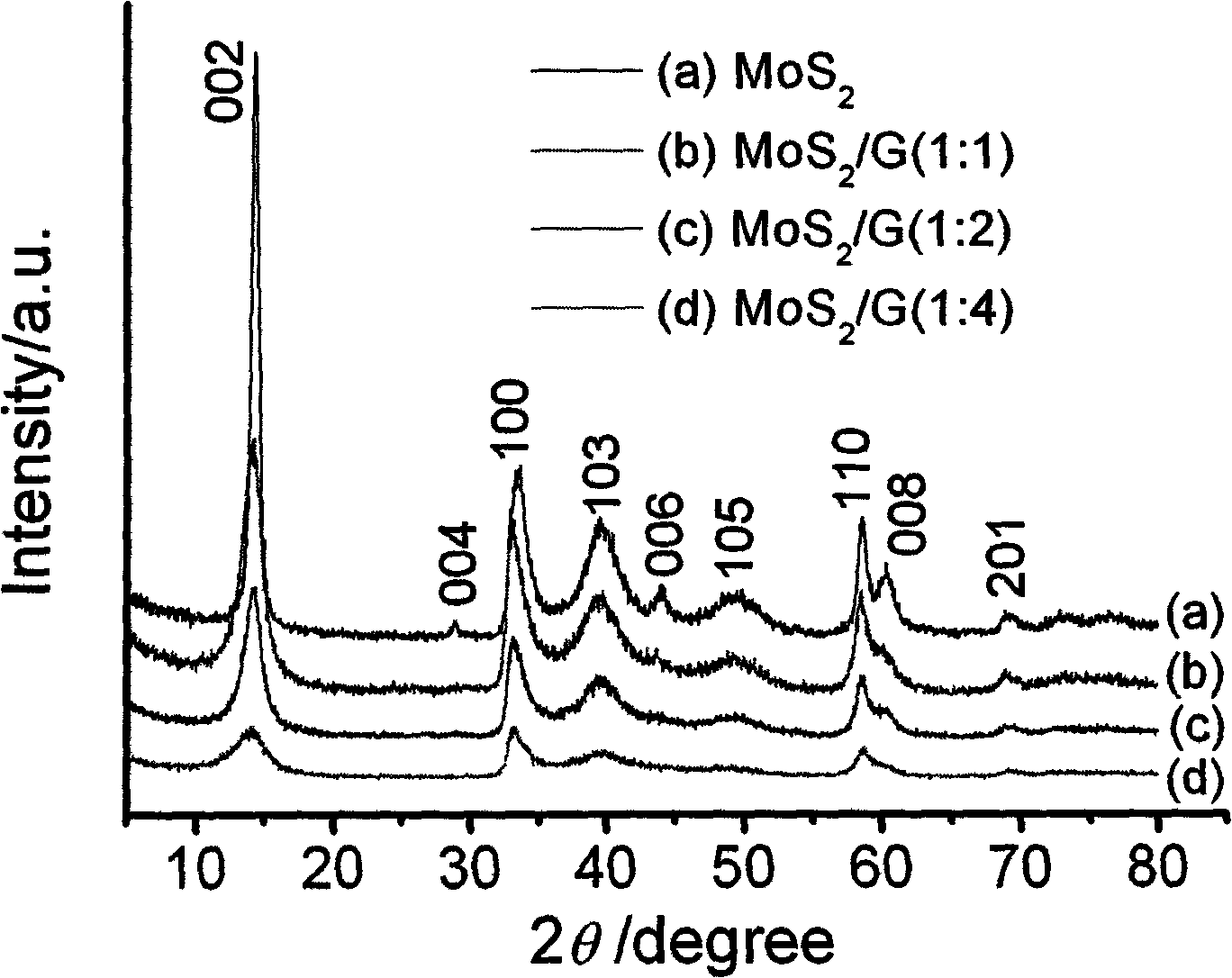

[0029] 2) Dissolve 1.25mmol (0.303g) sodium molybdate in 63ml of deionized water to form a 0.02M solution, add 6.25mmol of L-cysteine and stir evenly, the mixture of L-cysteine and sodium molybdate The ratio of mass is 5.0: 1, then the 1st) step is added in this solution with the pre...

Embodiment 2

[0033] A preparation method of electrochemical intercalation and extraction magnesium ion electrode with high capacity and stable cycle: 1) Preparation of graphite oxide nanosheets: disperse 2.5mmol (0.03g) of graphite powder into 25mL of concentrated sulfuric acid in an ice bath at 0°C , add KMnO with stirring 4 , the added KMnO 4 The mass of graphite is 4 times that of graphite, stir for 40 minutes, the temperature rises to about 33 ° C, add 50ml of deionized water, stir for 25 minutes, add 12ml of H2O with a mass concentration of 30% 2 o 2 , stirred for 5-10 minutes, centrifuged, and repeatedly washed with a mass concentration of 5% HCl solution, deionized water and acetone to obtain graphite oxide nanosheets;

[0034] 2) Dissolve 1.25mmol (0.303g) of sodium molybdate in 63ml of deionized water to form a 0.02M solution, add 7.5mmol of L-cysteine and stir evenly, wherein the amount of L-cysteine and sodium molybdate The ratio of the amount of substance is 6: 1, then t...

Embodiment 3

[0038]A preparation method for electrochemical intercalation and extraction of magnesium ion electrodes with high capacity and stable cycle: 1) Preparation of graphite oxide nanosheets: disperse 5.0 mmol (0.06 g) of graphite powder into 25 mL of concentrated sulfuric acid in an ice bath at 0 °C , add KMnO with stirring 4 , the added KMnO 4 The mass of graphite is 4 times that of graphite, stir for 50 minutes, the temperature rises to about 35°C, add 50ml of deionized water, stir for 30 minutes, add 20ml of H2O with a mass concentration of 30% 2 o 2 , stirred for 15 minutes, centrifuged, and repeatedly washed with a mass concentration of 5% HCl solution, deionized water and acetone to obtain graphite oxide nanosheets;

[0039] 2) Dissolve 1.25mmol (0.303g) sodium molybdate in 63ml deionized water to form a 0.02M solution, add 15mmol of L-cysteine and stir evenly, the amount of L-cysteine and sodium molybdate The ratio is 12: 1, then the 1st) step adds in this solution th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com