Flexible laminate having thermoplastic polyimide layer and method for manufacturing the same

The technology of a polyimide layer and a manufacturing method, which is applied to a flexible laminate having a thermoplastic polyimide layer and the manufacturing field thereof, can solve the problems of high dielectric constant and reduced heat resistance, and achieve adhesion Effects of excellent strength, excellent migration resistance, and excellent solder heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0148] A thermoplastic polyimide (AURUM (registered trademark) PD500A manufactured by Mitsui Chemicals Co., Ltd.) containing chemical structural formulas (6) and (7) in a ratio of 90:10 was used, Tg258[°C], melting point 380[°C] , to 500sec -1 The melt viscosity 700 [Pa·S] measured by the shear rate), the chemical structural formula is the thermoplastic polyimide (AURUM (registered trademark) PD450C of Mitsui Chemicals (KK) system of the above-mentioned formula (6); Tg250 [°C ], melting point 388[℃], in 500sec -1 The melt viscosity measured at the shear rate of 500 [Pa·S]) resin pellets, and the melt viscosity [Pa·S] of the thermoplastic polyimide resin used for extrusion molding is based on JIS K-7199 , Measured with Shimadzu Rheometer CFT-500.

[0149] After drying the above-mentioned resin particles at 180°C for 10 hours in a hot-air type high-temperature tank, use a single-screw extruder with a screw diameter of 50mm and a T-die installed at its front end to extrude the ...

manufacture example 2

[0151] The thermoplastic polyimide (AURUM (registered trademark) PD500A manufactured by Mitsui Chemicals Co., Ltd.) containing the chemical structure formula (6) and (7) in a ratio of 90:10; Tg258[°C], melting point 380[°C ], in 500sec -1 Melt viscosity measured at a shear rate of 700 [Pa·S]), the chemical structural formula is the resin particles of polyetherimide (ULTEM 1000P manufactured by General Electric Company) of the above-mentioned formula (13), and the above-mentioned Production Example 1 of Thermoplastic Polyimide Resin Film A thermoplastic polyimide resin film with a thickness of 50 μm (hereinafter referred to as thermoplastic PI film b) was obtained by the same method and corona discharge treatment.

[0152] Polyimide resin film:

[0153] The polyimide whose chemical structural formula is the above-mentioned formula (7) is generally sold as a polyimide resin film (Kapton 200H manufactured by DuPont-Toray Co., Ltd.), so this commercially available polyimide resin...

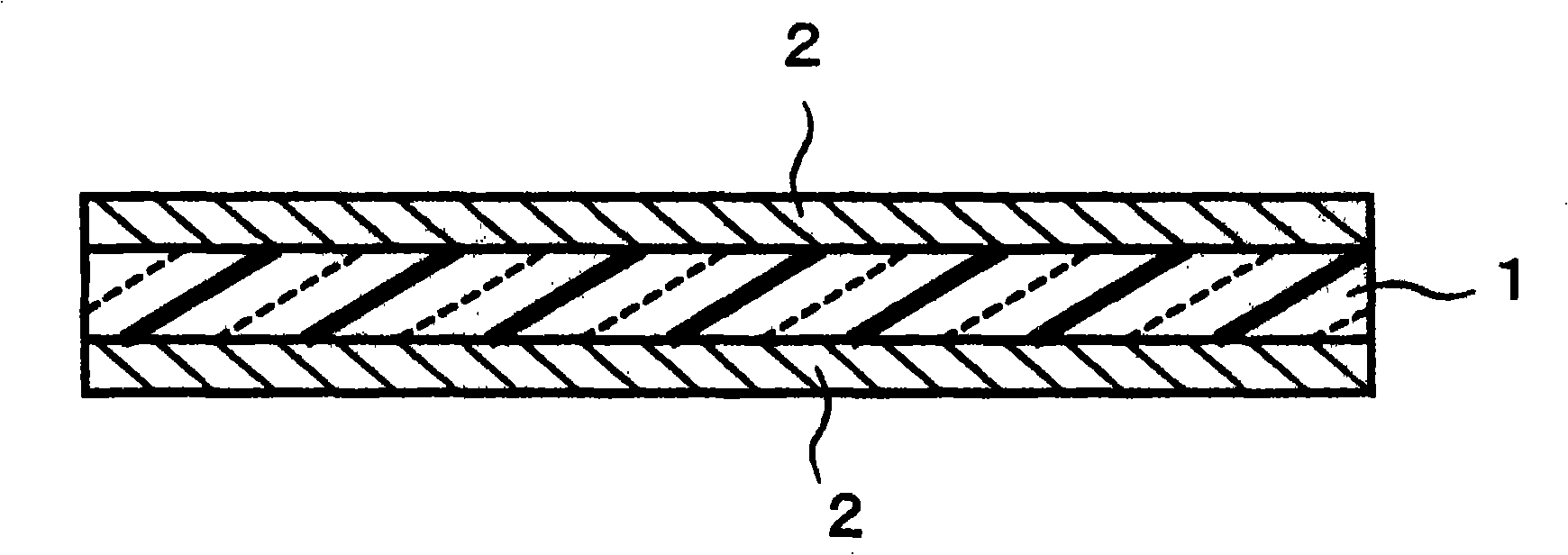

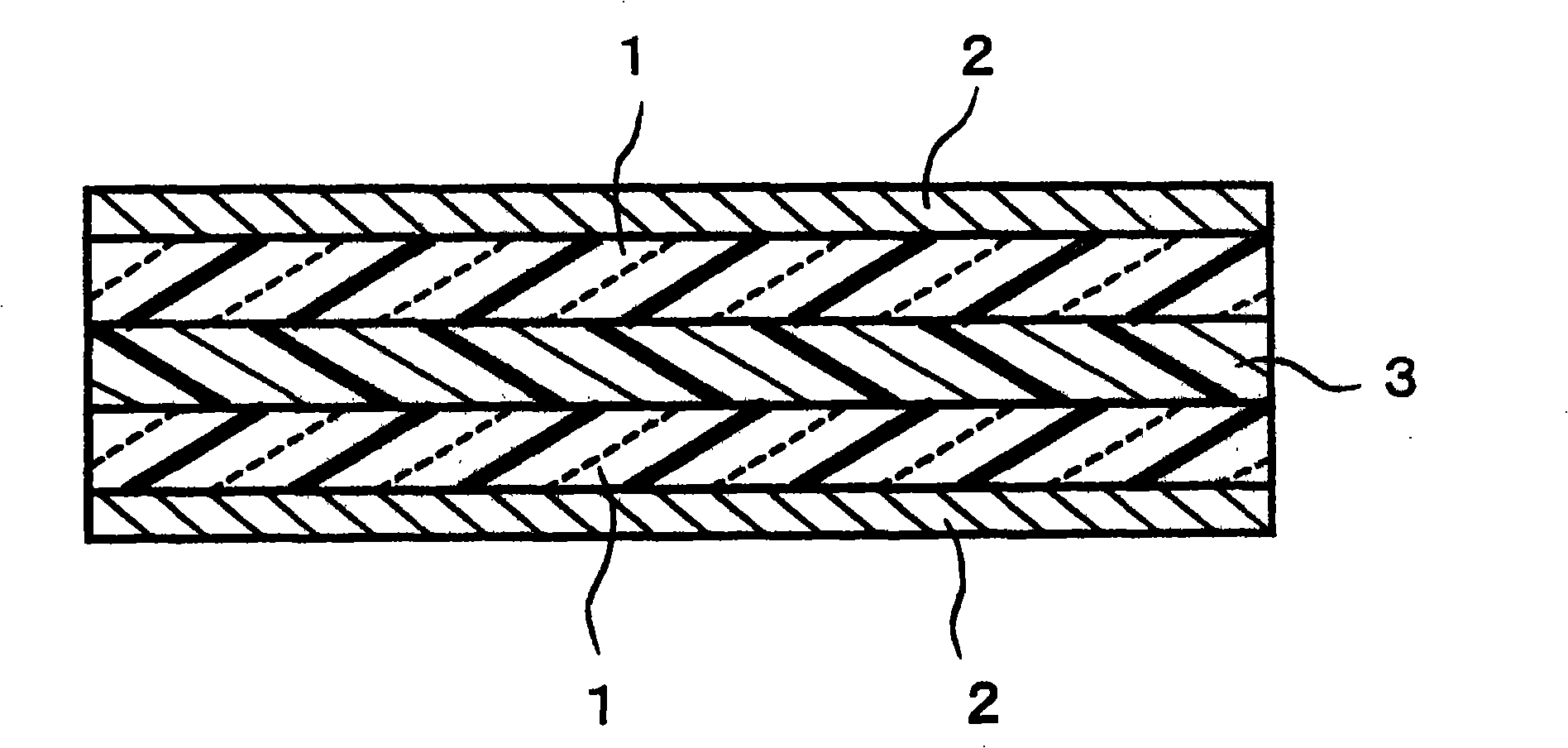

Embodiment 1

[0155] Copper foil with a thickness of 18 μm was laminated on both sides of a 50 μm thermoplastic PI film a. This was sandwiched from both sides by stainless steel plates (referred to as SUS plates). Further, FUJIRON STM manufactured by FUJICO Co., Ltd., which is a polybenzoxazole felt-like cushioning material laminated on both sides of the SUS plate, was installed in a vacuum high-temperature press machine manufactured by Kitagawa Seiki Co., Ltd. Then, reduce the pressure to 1.0kPa, at the initial pressure of 10kgf / cm 2 Under the pressure, after raising the temperature to 300°C at 5°C / min, increase the pressure to the secondary forming pressure of 25kgf / cm 2 , keep in this state for 10 minutes. Then, slowly cooled to room temperature, to obtain figure 2 The flexible double-sided copper-clad laminate substrate shown. The properties shown in Table 1 were evaluated using the obtained copper-clad laminate, and the results are shown in Table 1 together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com