Solvent-free conductive adhesive and preparation method thereof

A solvent-free, conductive adhesive technology, applied in the field of conductive adhesives, can solve the problems of easy aging, strong odor, and easy leakage of printing, etc., and achieve good electrical and thermal conductivity, broad application prospects, and low-cost practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

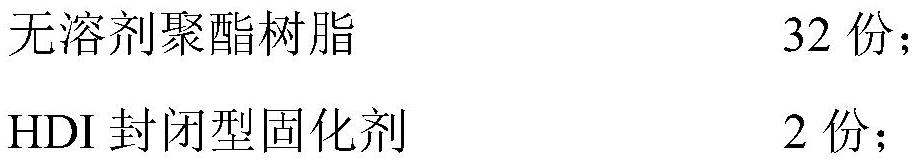

[0058] The solvent-free conductive adhesive in this example is composed of the following components by mass:

[0059]

[0060]

[0061] The preparation method of this solvent-free conductive adhesive in this example is as follows:

[0062] 1) Mix solvent-free polyester resin and dispersant BYK168 according to the proportion, and disperse evenly;

[0063] 2) Add single-walled carbon nanotube slurry MATRIX 201, and disperse at a high speed of 3000r / min for 1 hour until the fineness is ≤5μm;

[0064] 3) Add defoamer TEGO900 to disperse evenly;

[0065] 4) Add nano-silver powder and disperse evenly;

[0066] 5) Add HDI closed-type curing agent, disperse evenly, and obtain the finished product.

Embodiment 2

[0068] The solvent-free conductive adhesive in this example is composed of the following components by mass:

[0069]

[0070] The specific preparation method of this example is the same as that of Example 1.

Embodiment 3

[0072] The solvent-free conductive adhesive in this example is composed of the following components by mass:

[0073]

[0074] The specific preparation method of this example is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com