Process for producing shell powder supported solid acid biodiesel catalyst

A technology of biodiesel and shell powder, applied in catalyst activation/preparation, preparation of liquid hydrocarbon mixture, physical/chemical process catalyst, etc., can solve problems such as environmental pollution, expensive lipase, large amount of alcohol, etc., to improve catalytic performance Effects of activity and service life, elimination of sewage discharge problems, and ease of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

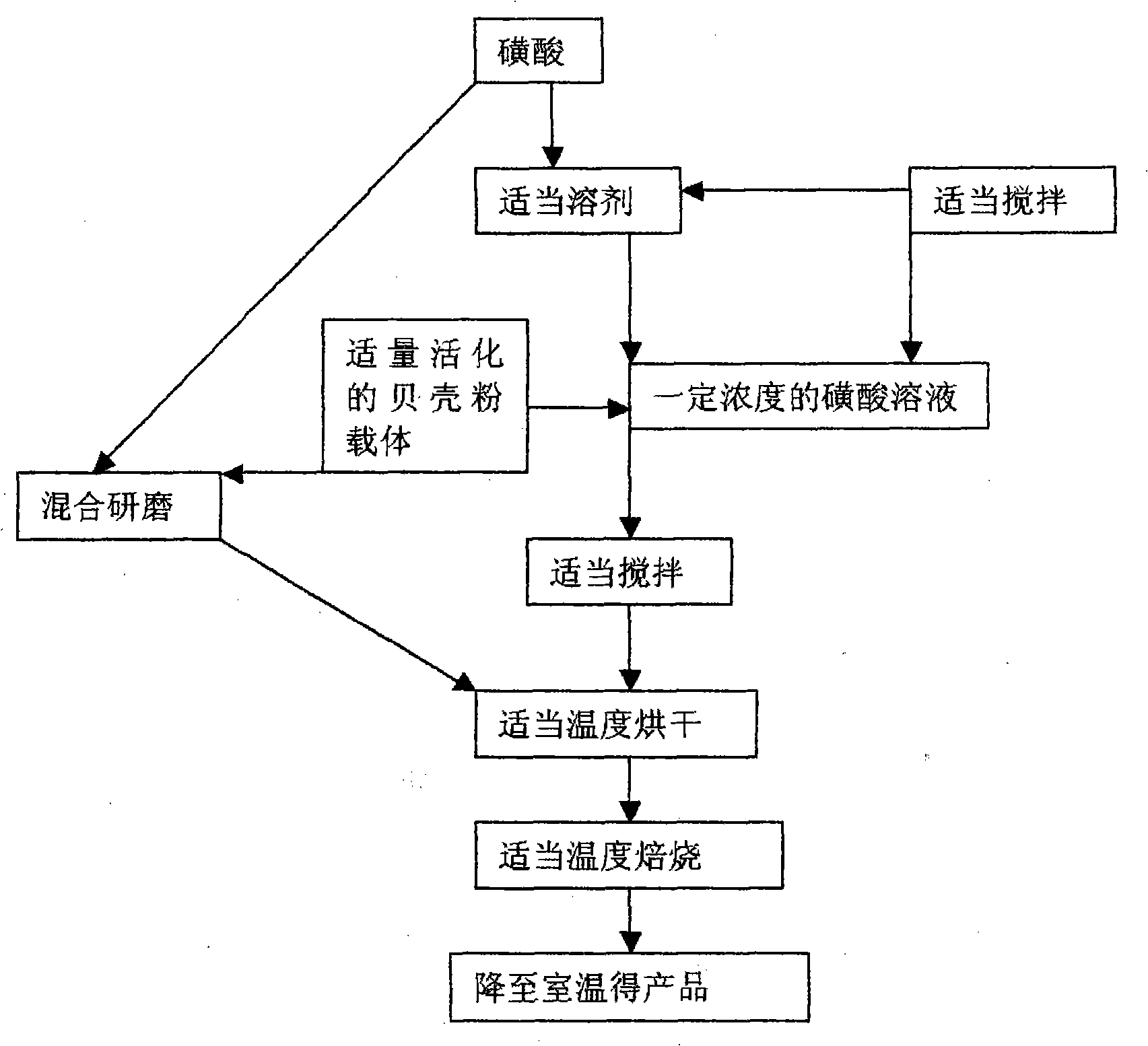

Method used

Image

Examples

Embodiment 1

[0024] At room temperature, dissolve 1 mmol of ethyl naphthalenesulfonic acid in 100ml of water, stir for 15 minutes, add 5 g of activated oyster shell powder to the sulfonic acid solution, load the sulfonic acid under stirring, dry at 60°C, and use the remaining sulfonic acid solution Rinse repeatedly to remove weakly bonded sulfonic acid, then dry at 60°C, bake in an oven, control the heating rate of 4K / min, heat up to 150°C, keep the temperature for 2 hours, then raise the temperature to 200°C, and keep the temperature for 10 hours. That is, the solid acid biodiesel catalyst immobilized by shell powder is obtained. In order to increase the load capacity, multiple loads can be carried out.

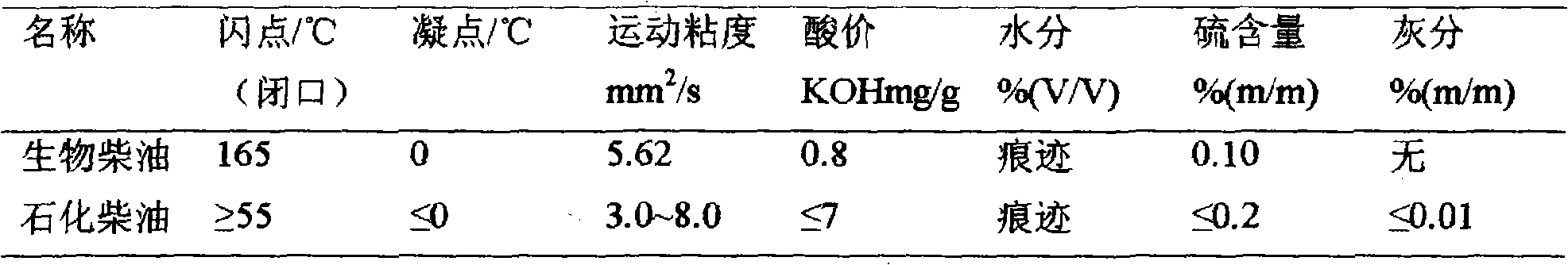

[0025] Catalyst activity test, in a 100ml three-neck flask equipped with electromagnetic stirring, a thermometer, and a reflux condenser, add 5g castor oil, 1.5g methanol, and 0.2g of the above-mentioned solid catalyst, heat and reflux and stir for 3h, distill methanol under reduced pres...

Embodiment 2

[0029] At room temperature, dissolve 1.5mmol of ethylnaphthalenesulfonic acid in 100ml of methanol, stir for 10min, add 5g of activated oyster shell powder to the sulfonic acid solution, load the sulfonic acid under stirring, dry at 70°C, and use the remaining sulfonic acid Rinse repeatedly with acid solution to remove weakly bonded sulfonic acid, then dry at 70°C, bake in an oven, control the heating rate of 5K / min, after heating to 150°C, keep the temperature constant for 3 hours, then raise the temperature to 180°C, and then keep the temperature constant After 15 hours, the solid acid biodiesel catalyst immobilized by shell powder was obtained. In order to increase the load capacity, multiple loads can be carried out.

[0030] The catalyst activity test was the same as in Example 1, and the yield of biodiesel reached 99.2%. The catalyst was recycled 12 times, and the yield of biodiesel was between 96-99.2%, and the catalytic activity did not decrease.

Embodiment 3

[0032] At room temperature, dissolve 2 mmol of p-ethylbenzenesulfonic acid in 100ml of methanol, stir for 10 minutes, add 5 g of activated oyster shell powder to the sulfonic acid solution, load the sulfonic acid under stirring, dry at 80°C, and use the remaining Rinse the sulfonic acid solution repeatedly to remove the weakly bonded sulfonic acid, then dry it at 80°C, bake it in an oven, control the heating rate of 6K / min, raise the temperature to 150°C, keep the temperature for 5h, then raise the temperature to 200°C, and then After constant temperature for 24 hours, the solid acid biodiesel catalyst immobilized by shell powder is obtained. In order to increase the load capacity, multiple loads can be carried out.

[0033] The catalyst activity test was the same as in Example 1, and the yield of biodiesel reached 99%. The catalyst was recycled 15 times, and the yield of biodiesel was between 96.5% and 99%, and the catalytic activity did not decrease.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com