Macromolecule modified flax and plastic alloy plate processing process and macromolecule modified flax and plastic alloy plate

A processing technology and polymer technology, which is applied to the processing technology field of automobile decorative materials, can solve the problems of difficult processing, no mention of the processing method of the corners of the hemp felt board, and pollution of the surrounding environment, and achieves the effect of improving performance indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

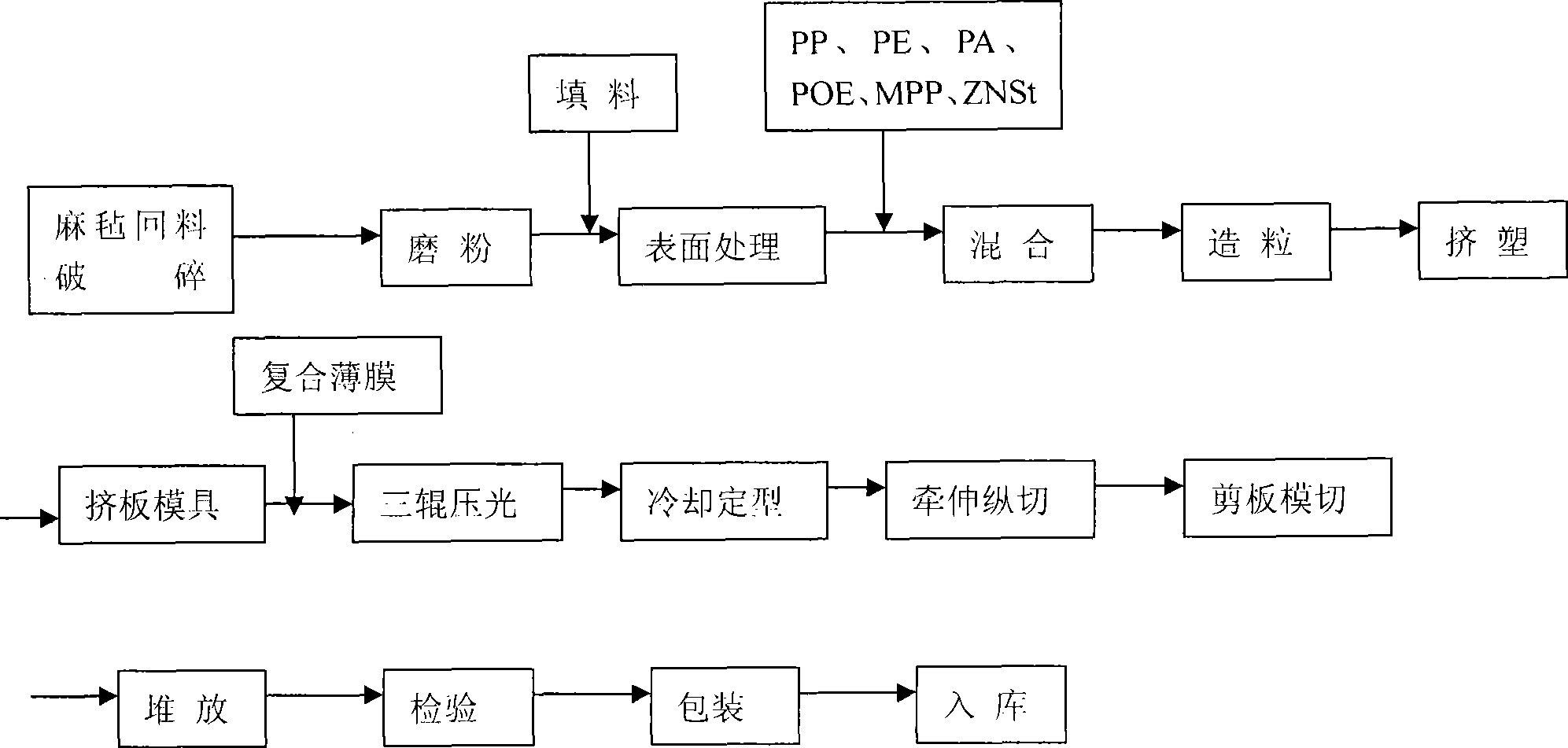

[0022] Such as Figure 1 Shown, the process flowchart of a kind of macromolecule modified hemp-plastic alloy plate of the present invention is specifically described as follows:

[0023] ①. Crushing process of hemp felt board waste recycling: cut the dry recycling into small pieces (about 100mm×100mm in size) with a saw blade machine, and put them into the crusher one by one. Do not pour in a large amount to avoid blade jamming die;

[0024] ②, Grinding process: After the crushed hemp felt board is recycled, the grinding process (80 mesh) is carried out to ensure uniform plasticization and smooth surface of the produced board;

[0025] ③, surface treatment process: the milled hemp felt powder, and the added filler (such as talcum powder and CaCO 3 ) after stirring and mixing, add coupling agent dropwise as required to carry out surface activation treatment;

[0026] ④ High-speed mixing process: according to the formula requirements, add all the ingredients, add them to the ...

Embodiment 2

[0044] A kind of polymer modified hemp-plastic alloy plate with embodiment 1, and its difference is: the weight percent of each component is:

[0045] Composite hemp felt board edge recycling 45%

[0046] Polypropylene 35%

[0047] Polyethylene 6.3%

[0048] Compatibilizer 3%

[0049] Toughener 5%

[0050] Lubricant 0.7%

[0051] Filler 5%

Embodiment 3

[0053] A kind of polymer modified hemp-plastic alloy plate with embodiment 1, and its difference is: the weight percent of each component is:

[0054] Composite hemp felt board edge recycling 60%

[0055]Polypropylene 30%

[0056] Polyethylene 2%

[0057] Compatibilizer 5%

[0058] Toughener 1%

[0059] Lubricant 1%

[0060] Filler 1%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com