Furniture sheet material film-pasting machine

A film laminating machine and plate technology, applied in the field of furniture manufacturing, can solve the problems of excessive glue, quality impact, uneven glue spraying, etc., and achieve the effect of avoiding accumulation and applying glue evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

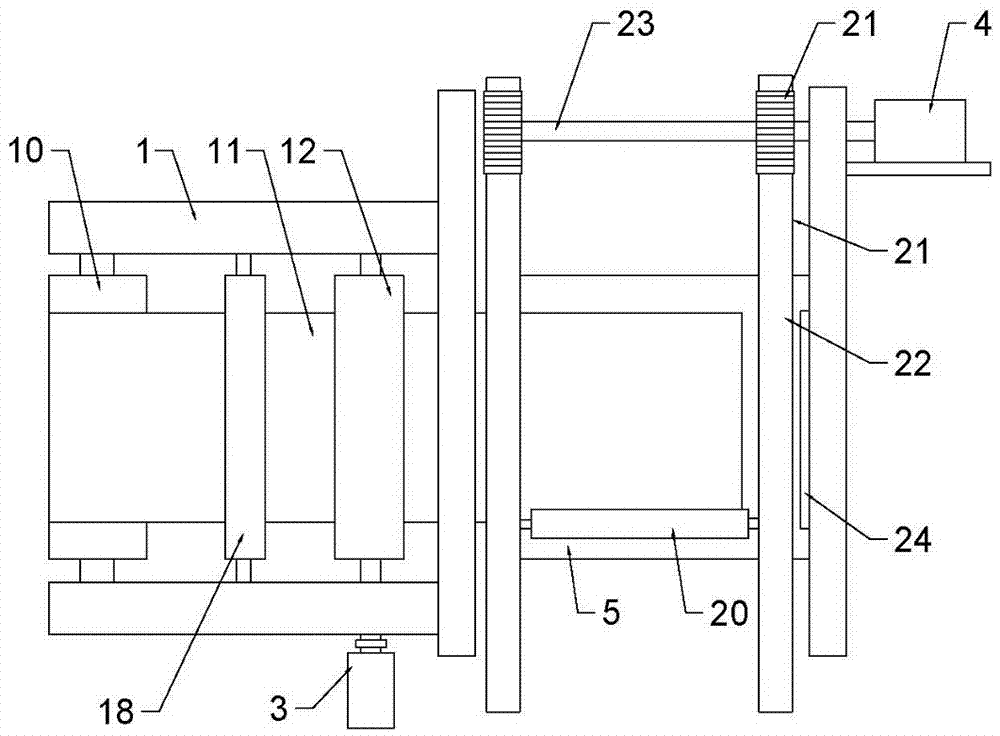

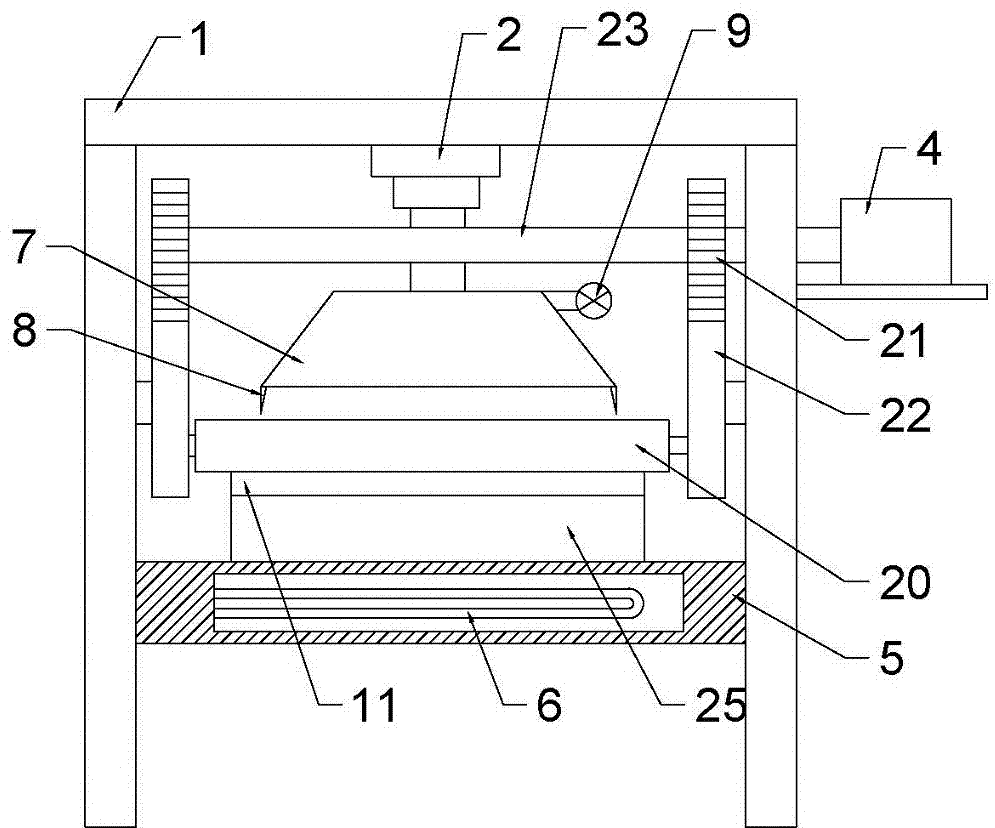

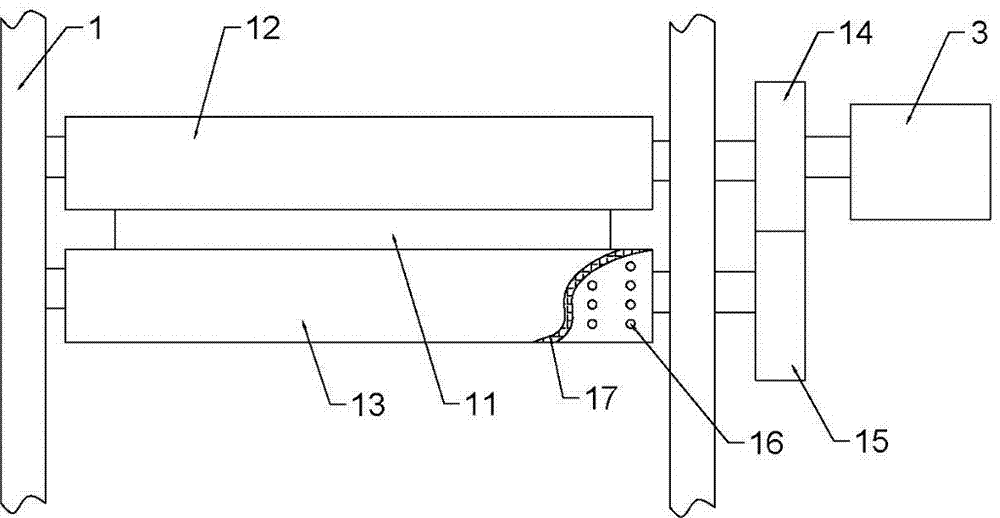

[0019] The reference signs in the drawings of the description include: frame 1, cylinder 2, first motor 3, second motor 4, support plate 5, heating resistor 6, vacuum box 7, blade 8, vacuum gauge 9, reel 10. Film 11, upper roller 12, lower roller 13, first gear 14, second gear 15, through hole 16, sponge layer 17, horizontal plate 18, through groove 19, pressure roller 20, third gear 21, rack 22, rotating shaft 23, strain gauge 24, plate 25.

[0020] Example basic reference Figure 1-Figure 4Shown: a film laminating machine for furniture boards, including a frame 1, on which a cylinder 2, a first motor 3, a second motor 4 and a support plate 5 are installed through bolts, the support plate 5 is a hollow structure, and the support plate 5 is set inside There is a heating resistor 6, a vacuum box 7 is installed on the frame 1 above the support plate 5, the cylinder 2 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com