Production method of ball valve core

A manufacturing method and a valve core technology, which are applied to valve devices, cocks including cutting devices, engine components, etc., can solve the problems of unreliable processing technology, thick metal pipes, and high defective rate, and achieve material saving, strength improvement, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the manufacture method of this ball valve spool, the metal plate 4 of the outer spherical shell 1 that selects to make the ball valve spool 1 of the present invention is stainless steel plate 4, and the thickness of stainless steel plate is about 1mm~1.5mm, according to the size of ball valve spool with cutting machine Cut it to the required length and its structure diagram is as follows figure 1 As shown, the installation hole 11 is punched out by a punching machine in the middle of the stainless steel plate, and its structural schematic diagram is shown in figure 2 shown.

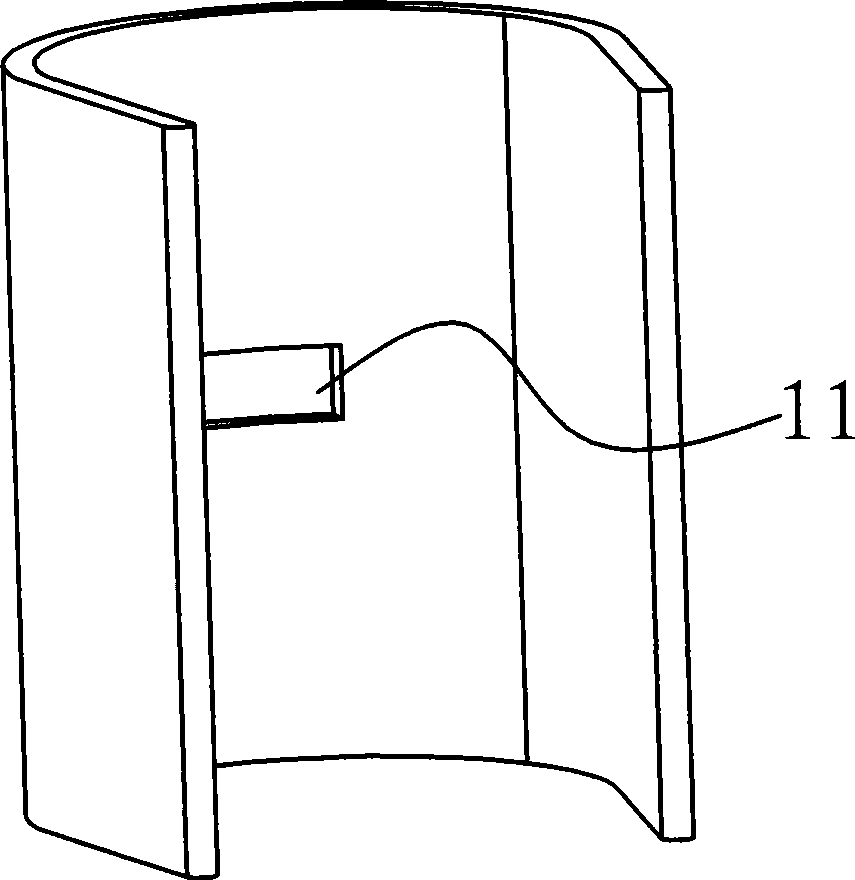

[0035] Select a suitable mold for making the metal round tube 5, put the stainless steel plate on the mold to bend it into a U shape, and then use a punch or punching machine on the mold to punch the U-shaped plate into a stainless steel round tube 5. Its structural diagram is as follows image 3 and Figure 4Shown; weld the pipe seam of the stainless steel round pipe 5 with a welding machine...

Embodiment 2

[0041] The selected stainless steel plate 4 did not punch out the installation hole 11 through a punching machine, and did not make the valve stem connecting seat 2 separately, but cut a straight seam with a saw blade milling cutter at the middle position of the two through holes of the outer spherical shell blank, and then used a deformation mold to cut a straight seam. Stamping makes valve stem groove 21, and it matches with the valve stem of ball valve. Other manufacturing processes are the same as in Embodiment 1, and will not be described in detail.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com