Cavity electrode

An electrode and cavity technology, applied in the field of medical devices, to simplify the production process, eliminate false welding failures, and reduce the rate of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

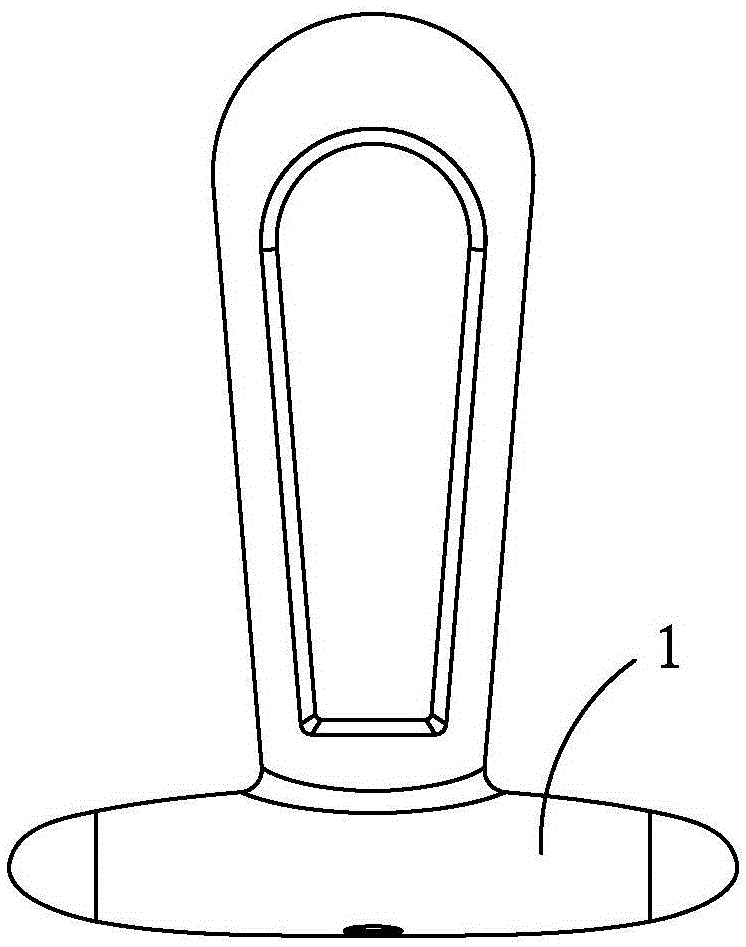

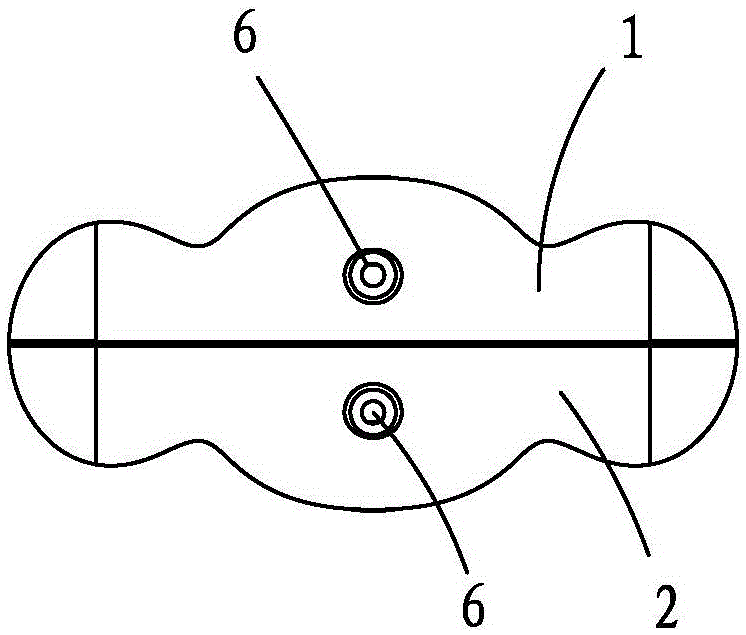

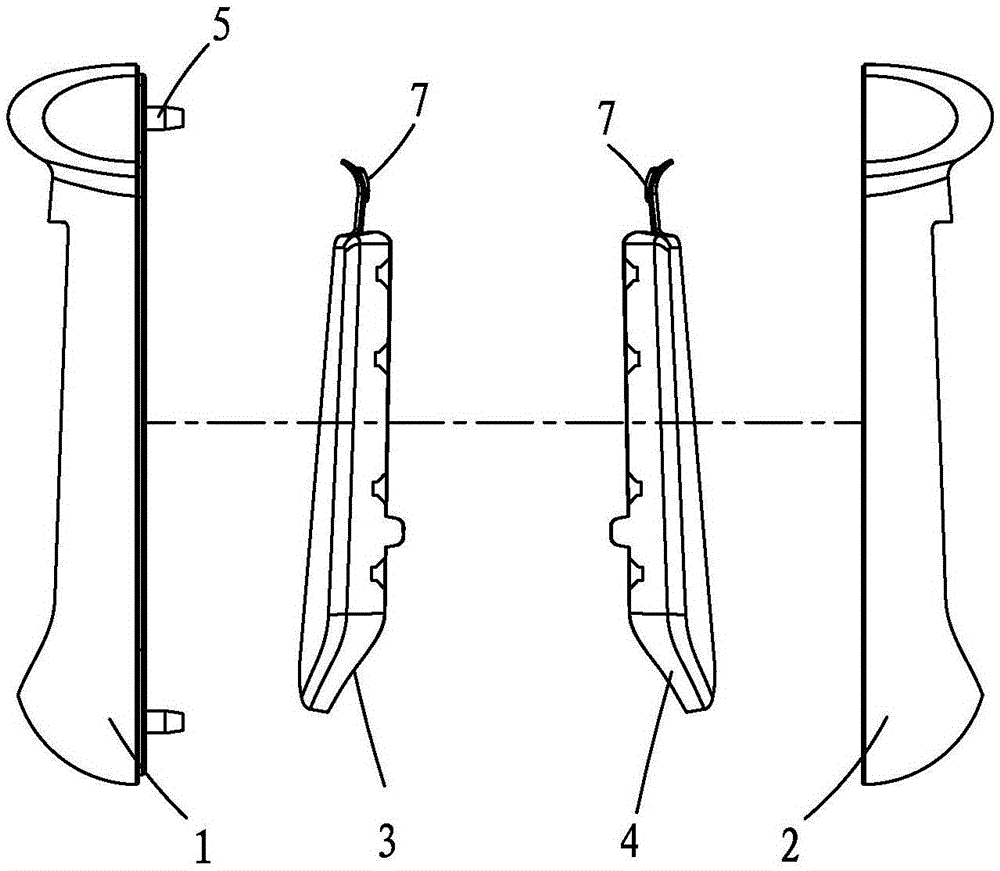

[0019] Please also see Figure 1 to Figure 4 As shown, a channel electrode includes an upper shell 1 and a lower shell 2 made of plastic thermoplastic molding, an upper electrode 3 and a lower electrode 4 made of conductive materials; the upper electrode 3 and the lower electrode The conductive material of 4 is made of stainless steel sheet stamping and forming; the upper shell 1 and the lower shell 2 are fixed and assembled into a hollow T-shaped structure with a smooth arc surface at the front end through the positioning device 5; the upper electrode 3 and the lower electrode 4 are respectively embedded in the upper case 1 and the lower case 2, and part of the surface is exposed through the windows of the upper case 1 and the lower case 2 to achieve the purpose of contacting the cavity. 1 and the end faces of the lower housing 2 are respectively provided with through holes 6, and the tail end faces of the upper electrode 3 and the lower electrode 4 are provided with bosses 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com