Preparation of ferric phosphate lithium composite material

A composite material, lithium iron phosphate technology, used in phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of slow solid-phase diffusion rate of reducing agents, high hydrothermal reaction temperature, and high production costs, and achieves conductive agent. The effect of uniform distribution, stable electrochemical performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

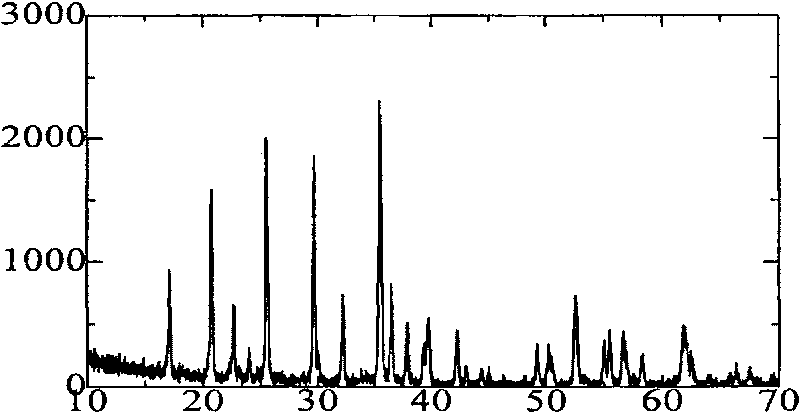

[0023] Lithium hydroxide: ferric hydrogen phosphate was mixed at a molar ratio of 1.2:1, and 5% carbon black was added according to the weight ratio of the reaction product, and placed in a vibrating ball mill for mixing and grinding for 1 hour; the grinding product was taken out, put into a porcelain boat, and placed In an electric furnace, under the protection of nitrogen at a flow rate of 5 liters / min, the temperature was raised to 500°C at a rate of 20°C / min, kept at a temperature of 20 hours, and then cooled to room temperature with the furnace, and the obtained product was product A. attached figure 1 It is the XRD pattern of product A, and the result shows that the product is LiFePO 4 , the crystal structure is complete.

[0024] Weigh 0.75 grams of product A, add 0.15 grams of carbon black and 0.1 grams of polytetrafluoroethylene, grind evenly, and prepare electrodes by coating method. Select a suitable positive electrode sheet, use the lithium sheet as the counter e...

Embodiment 2

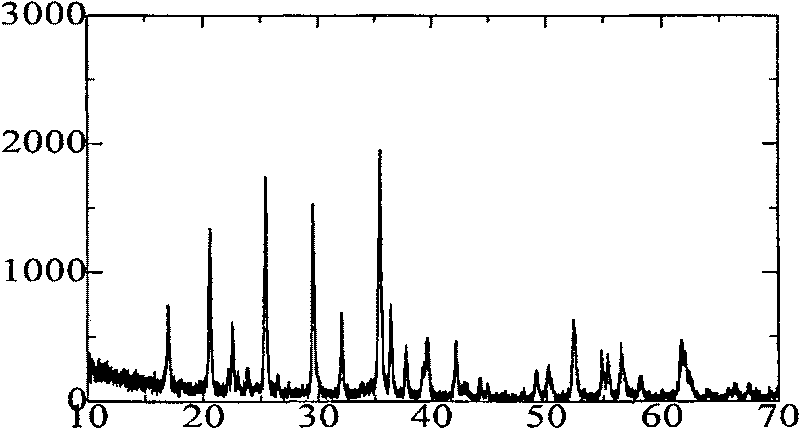

[0026] Lithium hydroxide: ferric hydrogen phosphate was mixed at a molar ratio of 1:1, and 5% sucrose was added according to the weight ratio of the reaction product, and placed in a roller mill for mixing and grinding for 10 hours; the ground product was taken out, put into a porcelain boat, and placed In an electric furnace, under the protection of argon with a flow rate of 1 liter / min, the temperature is raised to 800°C at a rate of 15°C / min, kept at this temperature for 2 hours, and then cooled to room temperature with the furnace, and the obtained product is product B . attached figure 2 It is the XRD pattern of product B, and the result shows that the product is olivine-type LiFePO 4 ;

[0027] According to the method of Example 1, the battery comprising the electrode made of product B was assembled and tested, and the results showed that its first discharge specific capacity was 147.4mAh / g, and the specific capacity after 10 cycles was 142.8mAh / g.

Embodiment 3

[0029] Lithium carbonate: ferric hydrogen phosphate was mixed at a molar ratio of 0.5:1, and 10% glucose was added in the weight ratio of the reaction product, and placed in a planetary ball mill for mixing and grinding for 2 hours; Under the protection of nitrogen, the temperature was raised to 600°C at a rate of 20°C / min, kept for 12 hours, and then cooled to room temperature at a cooling rate of 3°C / min. The obtained product was product C, and the results showed that the product was LiFePO 4 .

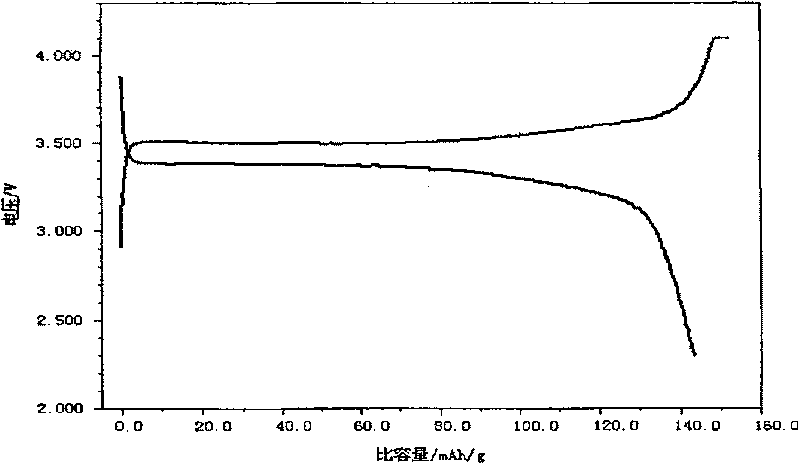

[0030] According to the method of Example 1, the battery comprising the electrode made by product C was assembled, tested at room temperature and 1C current density, the results showed that its initial discharge specific capacity was 143.6mAh / g, and the specific capacity after 20 cycles was 142.8mAh / g. g; the first charge and discharge curve and cycle performance chart are as attached image 3 , attached Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com