Acidic coating super two-phase stainless steel electrode

A technology of duplex stainless steel and coating, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of difficult ferrite-austenite phase structure ratio, high manufacturing difficulty and high strength. Achieve the effect of excellent pitting resistance, excellent mechanical properties and excellent operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The mass percentages of electrode coating composition and content are: rutile 35, potassium feldspar 20, marble 6, phlogopite 1.5, titanium dioxide 5, molybdenum iron 2, metal manganese 2, metal chromium 18, cryolite 2, fluoride rare earth 1.5 , Soda Ash 1.0, Chrome Green 6.

Embodiment 2

[0022] The mass percentages of electrode coating composition and content are: rutile 37, potassium feldspar 17, marble 5, phlogopite 3, titanium dioxide 7, molybdenum iron 3.5, metal manganese 3, metal chromium 13, cryolite 2.5, fluoride rare earth 0.5 , soda ash 0.5, chrome green 8.

Embodiment 3

[0024] The mass percentages of electrode coating composition and content are: rutile 40, potassium feldspar 15, marble 10, phlogopite 1, titanium dioxide 3, molybdenum iron 1.5, metal manganese 3.5, metal chromium 16.5, cryolite 3, fluoride rare earth 1 , soda ash 0.5, chrome green 5.

[0025] Example 2 Effect

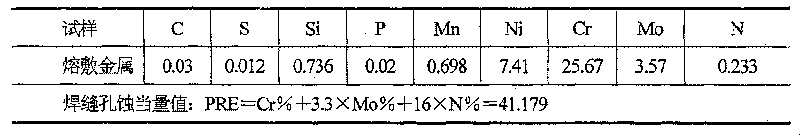

[0026] Chemical composition of deposited metal %

[0027]

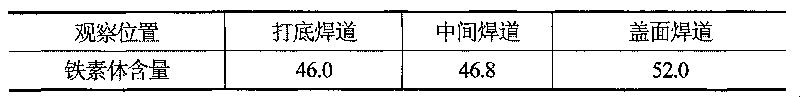

[0028] Ferrite content in weld metal %

[0029]

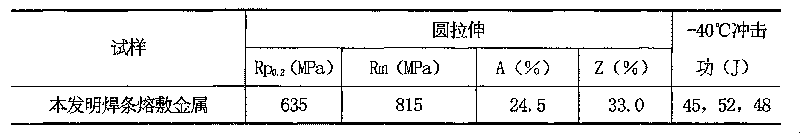

[0030] Deposited Metal Mechanical Properties

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com