Positive electrode material of multi-component composite lithium ion cell and its preparation method

A lithium-ion battery and cathode material technology, applied in the field of lithium-ion battery cathode materials and its preparation, can solve the problems of gas swelling, explosion, and difficulty in uniform mixing of various elements, etc., and achieve the effect of low preparation cost and controllable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

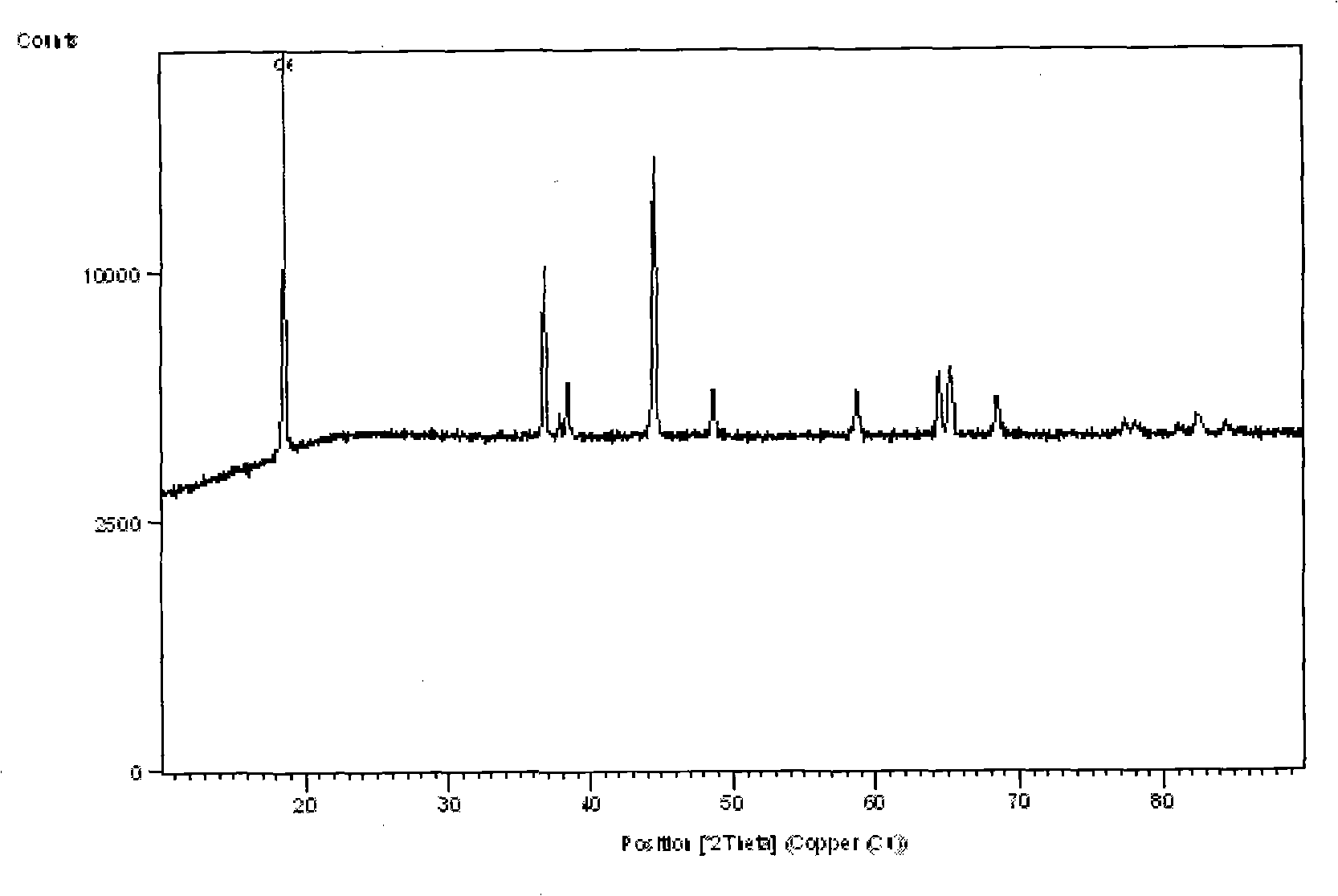

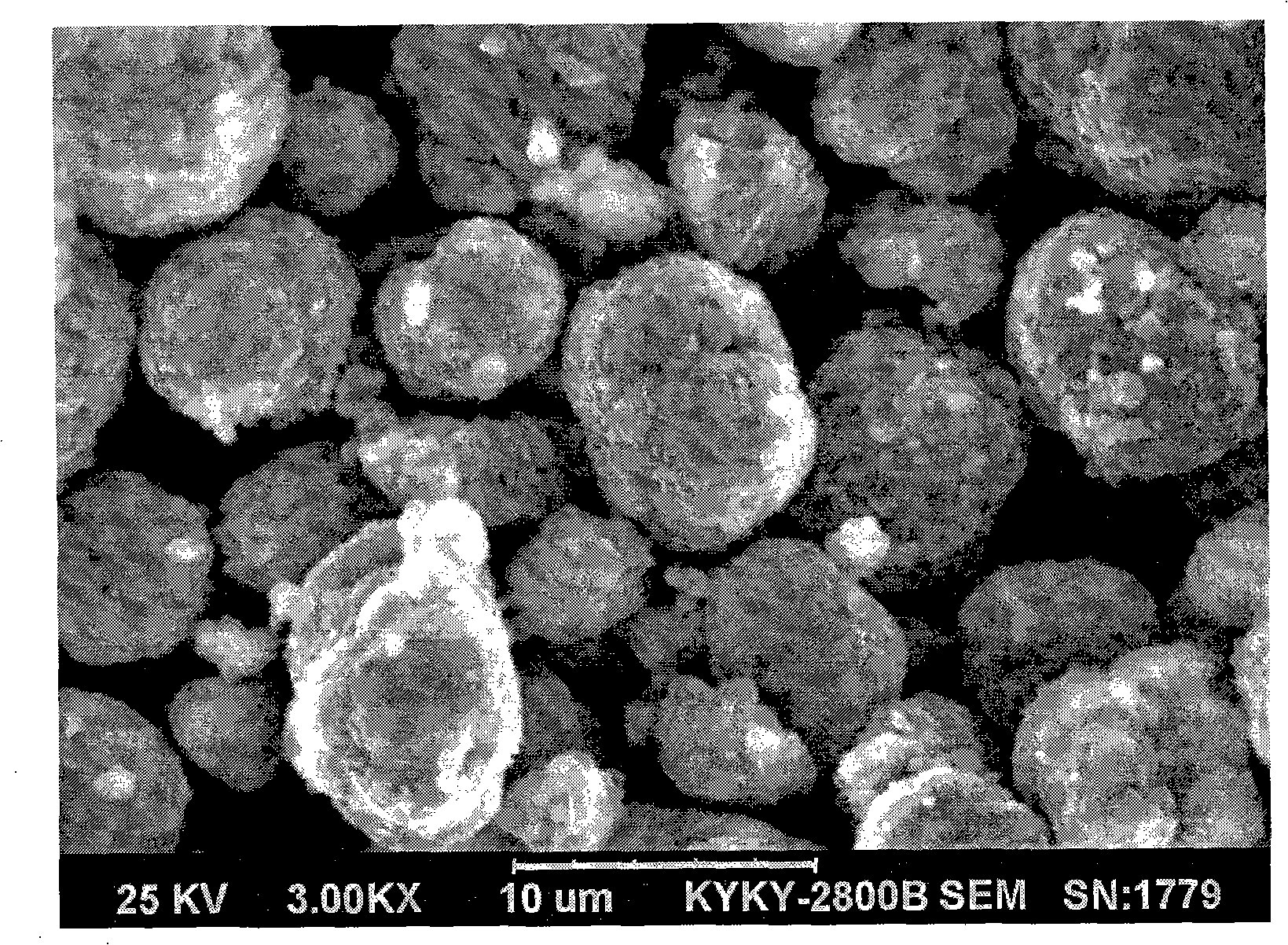

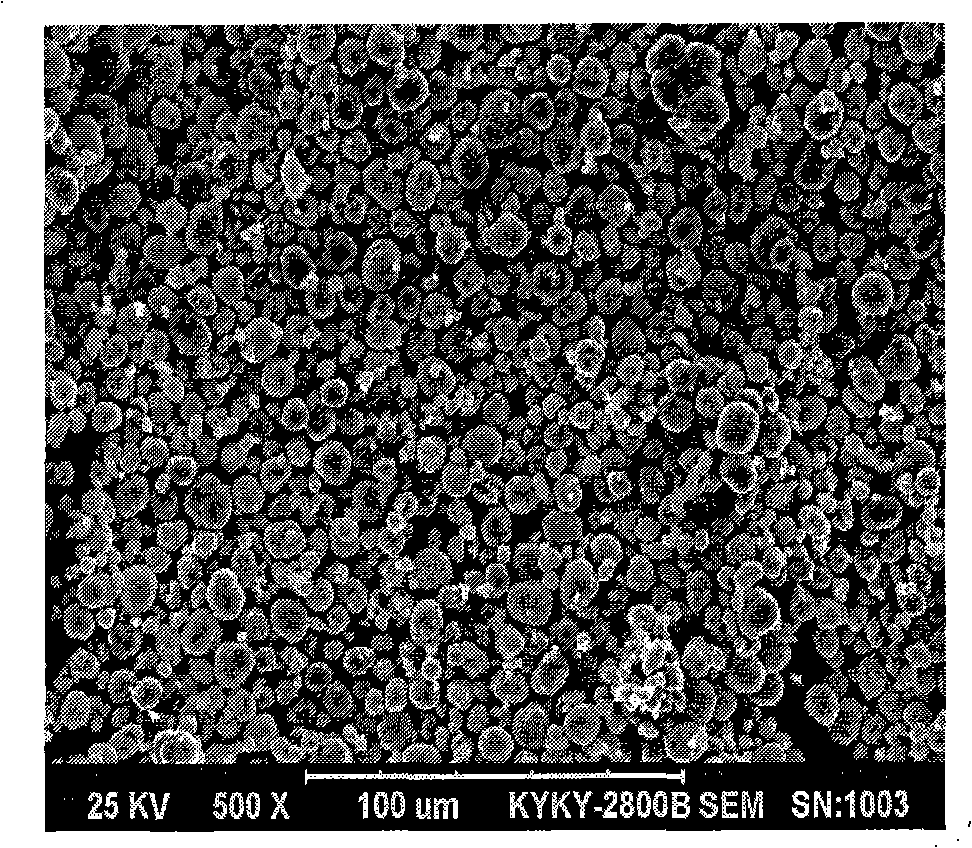

Image

Examples

preparation example Construction

[0023] The multi-element composite lithium-ion battery cathode material of the present invention and preparation method thereof, adopt the following steps:

[0024] 1. Synthesis of matrix materials, respectively prepare alkali solution lithium hydroxide or sodium hydroxide with a concentration of 0.5-8 mol / L, Ni salt solution, Co salt solution and Mn / Al salt solution with a concentration of 0.5-8 mol / L, in In the prepared Ni salt solution, Co salt solution and Mn / Al salt solution, add 0-2% additives by mass respectively, the additives are ammonia water, ethylene glycol, ethylenediamine, sodium dodecyl-hexadecylsulfonate and more than one of polyethylene glycol. At the same time, add it into the reaction kettle at the same flow rate, the flow rate is 10-100L / h, and stir continuously to make it form a uniform precipitate. At the same time, control the dropping speed of the alkali solution to adjust the pH value of the solution between 8 and 11.5.

[0025] 2. Matrix lattice dopi...

Embodiment 1

[0032] Embodiment 1, prepare the sodium hydroxide alkali solution of 2mol / L concentration earlier, prepare the nickel nitrate, cobalt, manganese salt solution that the molar ratio of 1mol / L is 5:3:2, preparation concentration is the whole solution quality 2% simultaneously For the mixed solution of ammonia water and ethylene glycol, the prepared solutions are simultaneously added to the reaction kettle at a flow rate of 60L / h, and continuously stirred to form a uniform precipitate, and the pH value of the solution is adjusted at 10.8 by controlling the dropping speed of the alkali solution .

[0033] When the ion concentration of Ni, Co, and Mn is 600pmm, add 0.6mol / L aluminum nitrate solution to the solution at a certain rate of 30L / h, and stop the reaction when the ion concentration is lower than 200pmm.

[0034] Filter the precipitated powder in a vacuum filter, measure the pH value of the filtrate to 5, and titrate the filtrate with barium nitrate. When there is no obvious...

Embodiment 2

[0037] Embodiment 2, prepare the lithium hydroxide alkaline solution of 0.5mol / L concentration earlier, prepare the nickel nitrate, cobalt, manganese salt solution that the molar ratio of 0.5mol / L is 5:3:2, preparation concentration is the whole solution quality 0.5 simultaneously % mixed solution of ammonia water and ethylenediamine, each prepared solution is added to the reaction kettle at the same time at a flow rate of 10L / h, and continuously stirred to form a uniform precipitate, and the pH value of the solution is adjusted by controlling the dropping speed of the alkali solution at 8.

[0038] When the concentration of Ni, Co and Mn ions is 200pmm, add 0.6mol / L titanium nitrate and aluminum nitrate solution to the solution at a certain rate of 10L / h, and stop the reaction when the ion concentration is lower than 200pmm.

[0039] Filter and wash the precipitated powder in a vacuum filter, measure the pH value of the filtrate to be around 5, and titrate the filtrate with b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com