Pattern exposure method and pattern exposure apparatus

An exposure method and pattern technology, which are applied in microlithography exposure equipment, photolithography exposure devices, optics, etc., can solve the problem of processing capacity (low productivity, long positioning, gap adjustment and exposure time, and inability to expose periodic patterns) And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] Best Mode for Carrying Out the Invention

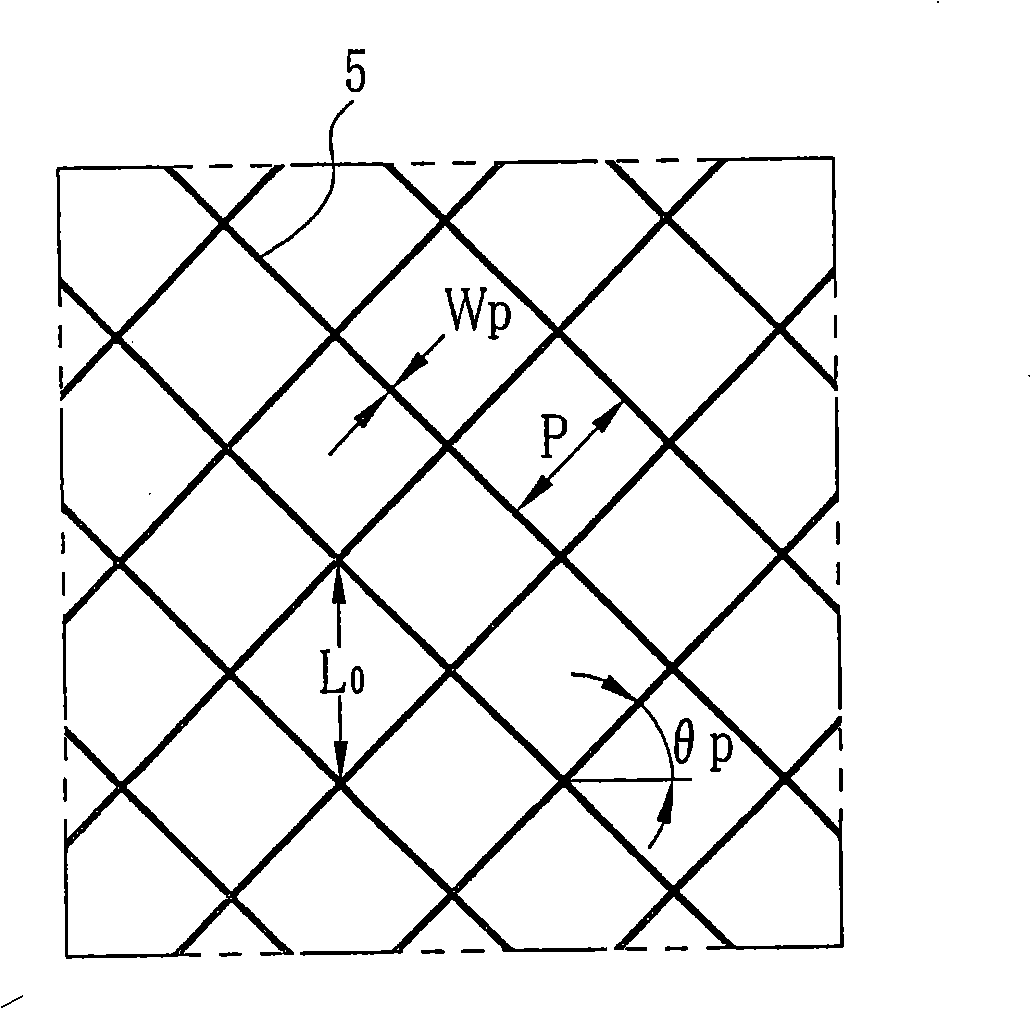

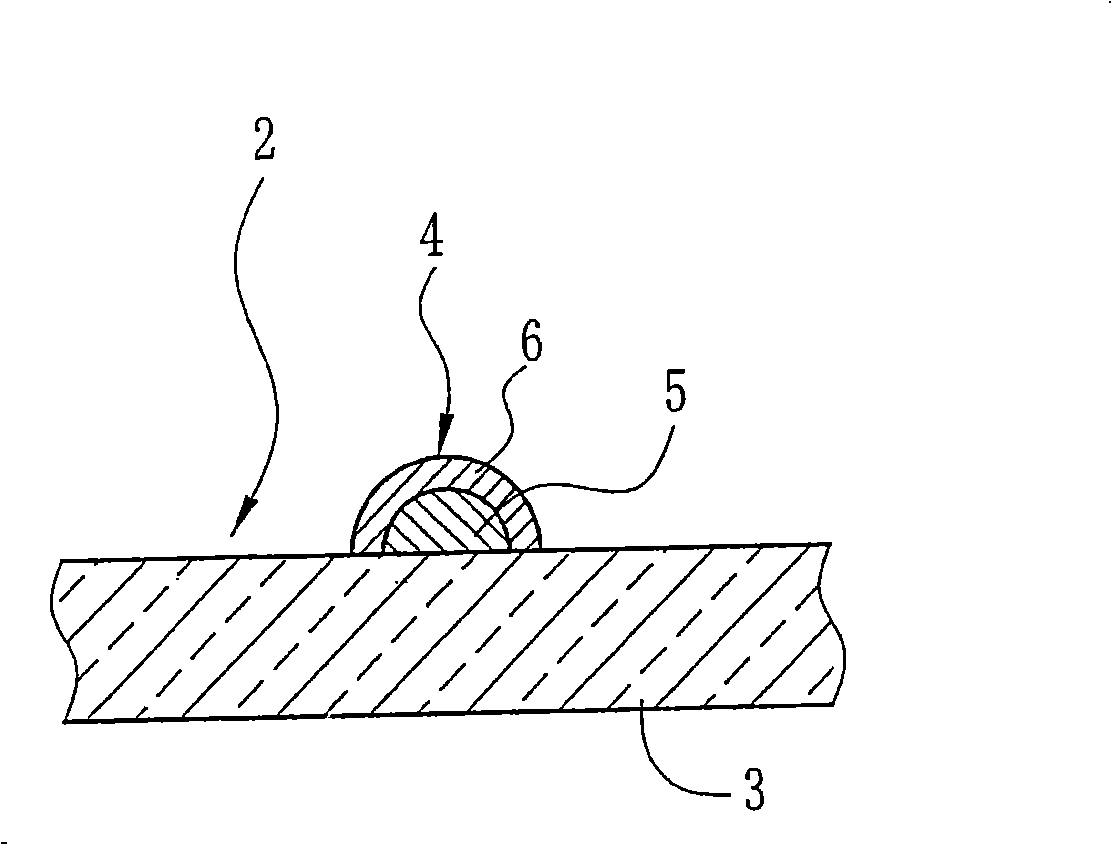

[0103] Such as Figure 1A As shown in , the electromagnetic shielding film 2 includes a transparent film 3 and a grid-like electromagnetic shielding pattern 4 of silver salt formed on the transparent film 3 . Such as figure 2 As shown in , the electromagnetic shielding pattern 4 is composed of a periodic pattern 5 formed of silver salt on a transparent film 3 and a copper plating layer 6 plated on the surface of the periodic pattern 5 for providing an electromagnetic shielding function. as in partially enlarged form Figure 1B As shown in , the periodic pattern 5 has thin lines arranged at right angles to each other at a pitch P of 300 μm and an alignment angle θp of 45°, each of which has a width Ws of 10 μm to 20 μm.

[0104] As shown in Figure 3, the pattern exposure apparatus 10 that is used to form periodic pattern 5 comprises: workpiece supply part 12, is used for supplying the tape-sample workpiece 11 as transparent f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com