Method for preparing hollow northylen of ultra-high relative molecular mass

A relative molecular weight, polyethylene fiber technology, applied in the manufacture of hollow filaments, single-component polyolefin artificial filaments, fiber chemical characteristics, etc., can solve problems such as high strength and high modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The ultra-high molecular mass polyethylene (UHMWPE) powder with a weight average relative molecular weight of 5,000,000 and mineral oil are prepared in a ratio of 10:90 by weight to form a suspension, and the weight ratio of UHMWPE powder to antioxidant is 1000 Add antioxidant 1010 at a ratio of : 6, and obtain a spinning dope by swelling and dissolving at high temperature.

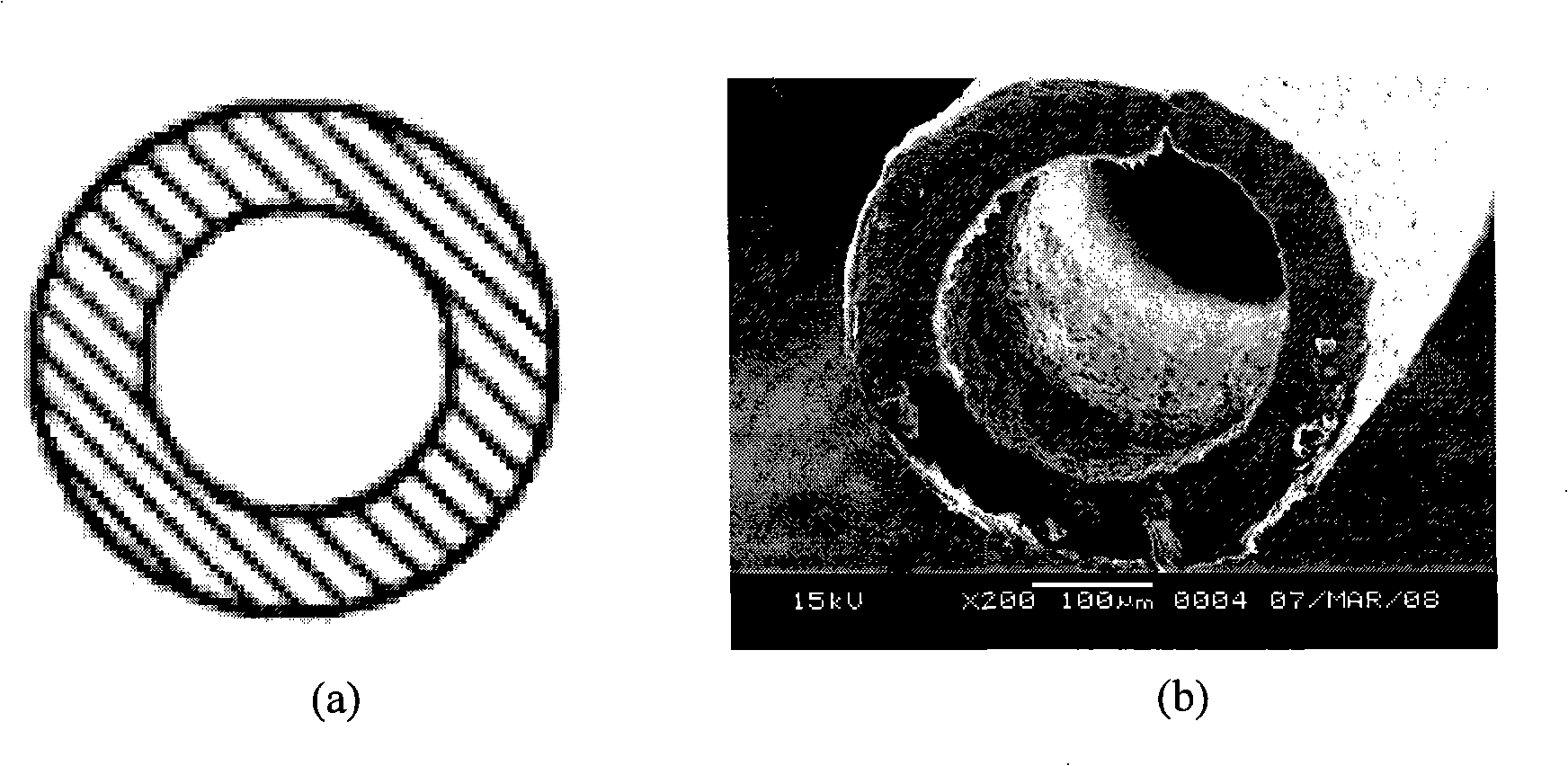

[0026] A C-type hollow spinneret with an outer diameter of 0.8 mm, a slit gap of 0.2 mm, and a frame width of 0.08 mm was used. The spinning dope is sprayed out through the slit of the C-type hollow spinneret at 240°C, passes through a 10mm air layer, and directly enters a pure water coagulation bath at 5°C to be quenched into hollow jelly fibers. The cross-section and longitudinal micrographs of the resulting hollow jelly fibers are shown in figure 1 As shown, the schematic diagram of the fiber cross-section and the scanning electron microscope photo are shown in figure 2 As shown, the fiber ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com