Film material with ionic exchange performance and use thereof

A technology of ion exchange and exchange performance, which is applied in the field of polymer membranes, can solve the problems of decreased stability of mechanical properties and high transfer resistance, achieve low mass transfer resistance, high chemical stability, and overcome low chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

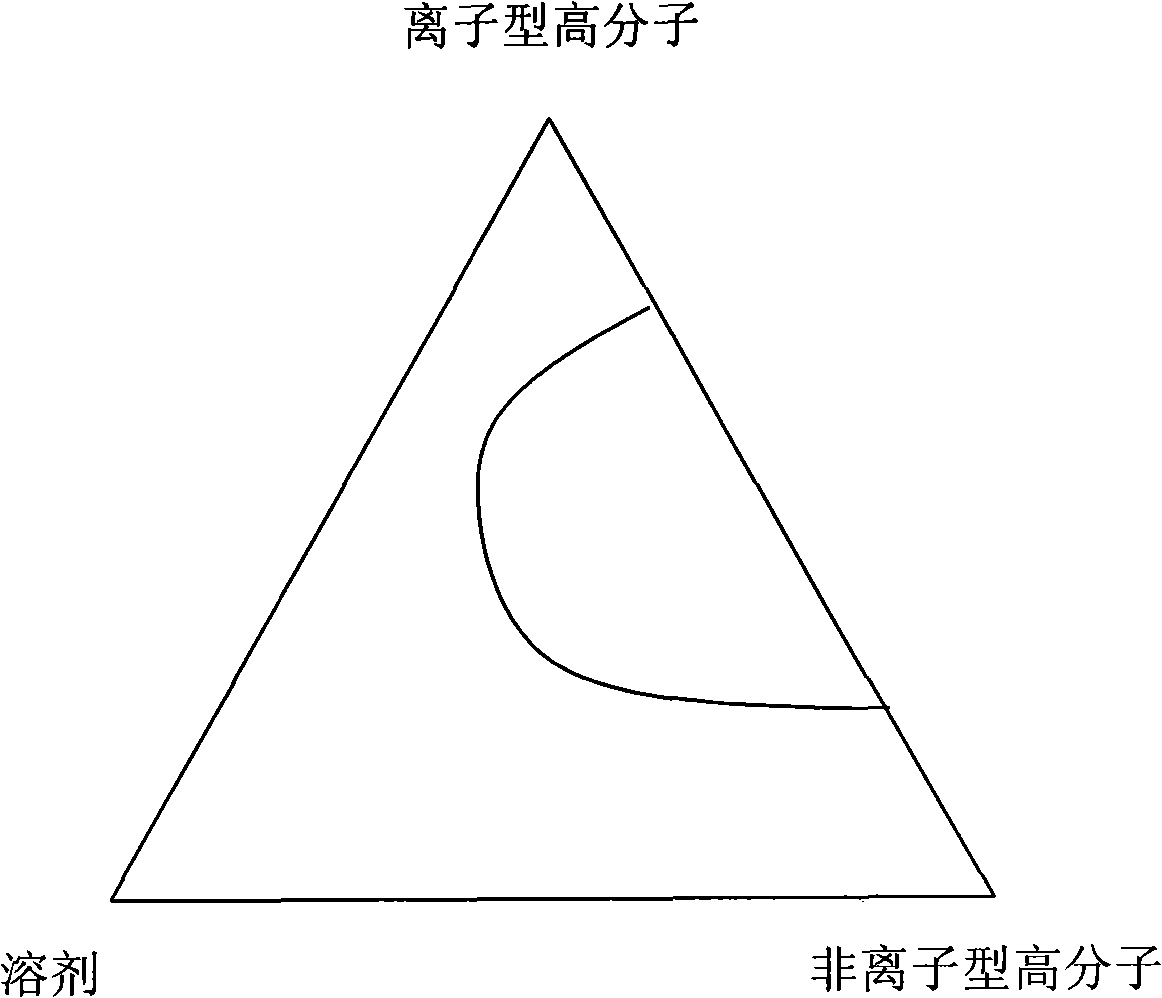

[0042] 100 grams of polyetheretherketone (450PF, Victrix) was modified by sulfonation in 1 liter of concentrated sulfuric acid, the sulfonation temperature was kept at 20±0.5oC, and the sulfonation reaction time was 120 hours. The degree of sulfonation of the obtained sulfonated polyether ether ketone was 0.85, and the ion exchange capacity (Ion exchange capacity) was 2.3 meq / g. Solubility measurements showed that the polymer was soluble in nitrogenmethylpyrrolidone NMP at room temperature. Prepare 20wt% SPEEK / NMP solution, and mix it with polysulfone / NMP solution of the same concentration at a ratio between 30 / 70 and 70 / 30 (percentage by weight), and fully stir and mix evenly.

[0043] The mixed polymer solution was applied to a smooth and clean glass plate with a scraper with a thickness of 200 microns, and after staying in the air for 10 seconds, it was placed in a blast oven at a temperature of 100 degrees to evaporate the solvent. When the solvent evaporates completely, ...

Embodiment 2

[0046] In the first step, 50 grams of polyetheretherketone (450PF, Victrix) was added into 1 liter of concentrated sulfuric acid under stirring, and the temperature was kept at 25° C., so that the polyetheretherketone was fully dissolved. Then the temperature of the system was lowered to 0°C, 10 g of chloromethyl ether was added, and the temperature was raised to 15°C for 9 hours. The polymer was precipitated from the reaction solution in water, and then washed repeatedly with water until neutral. After drying, refining (using chloroform) to obtain chloromethyl polyether ether ketone. The degree of chloromethylation (DCM) of the polymer is 1.8mmol.g-1 dry resin, and the solubility test shows that it is soluble in polar solvents such as nitrogen methylpyrrolidone and the like. In the second step, prepare 20wt% chloromethyl polyether ether ketone / NMP solution, and mix it with the polyethersulfone / NMP solution of the same concentration (percentage by weight) between 30 / 70 and 70...

Embodiment 3

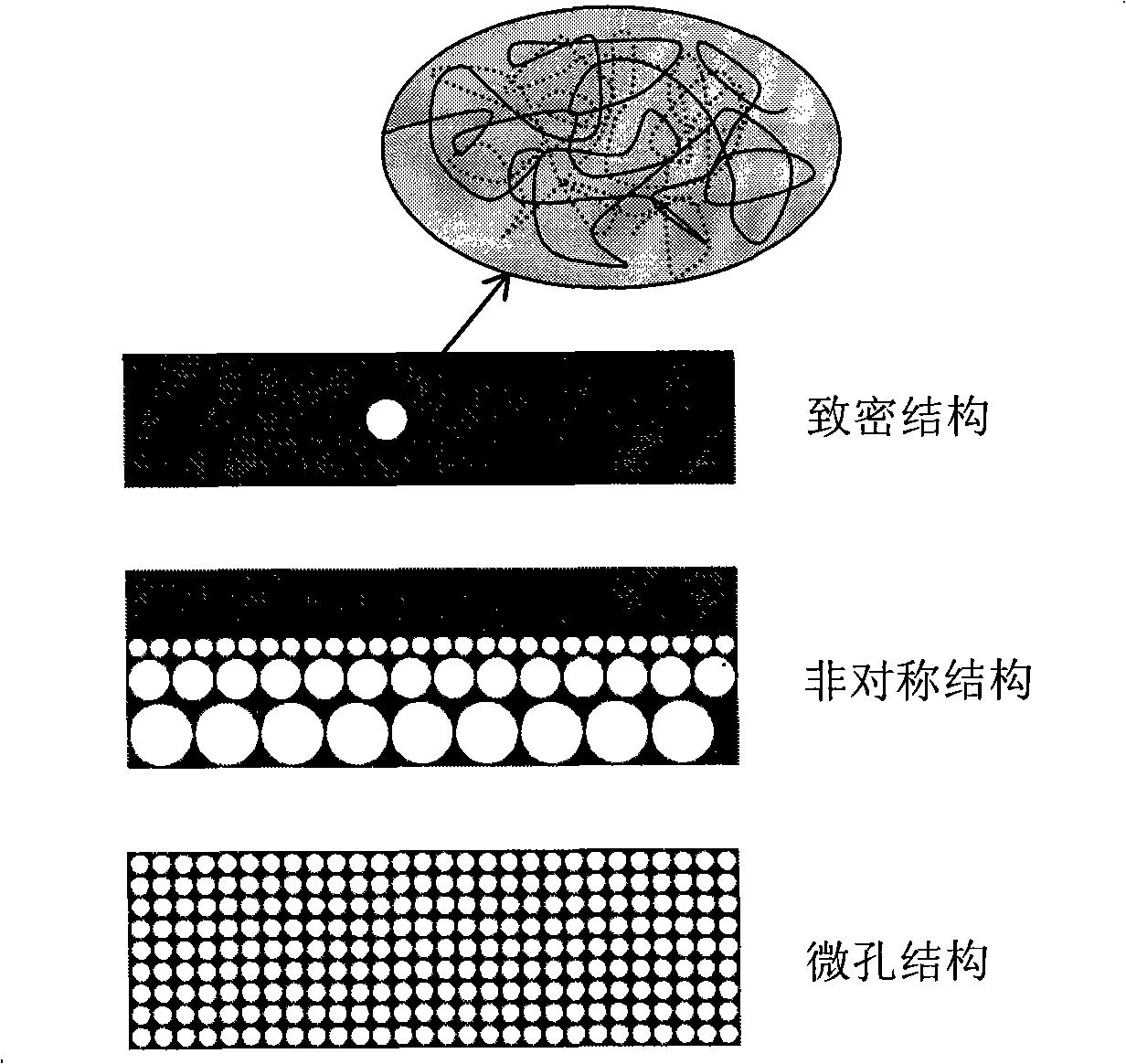

[0049] The sulfonated polyetheretherketone in Example 1 was used. Prepare 30wt% SPEEK / NMP solution, and mix it with polyethersulfone / NMP solution of the same concentration at a ratio of 30 / 70 to 70 / 30 (percentage by weight), fully stir and mix evenly at 100 degrees. Apply the mixed polymer solution to a smooth and clean glass plate with a scraper with a thickness of 200 microns, stay in a blast oven at 150 degrees for 60 seconds, and then place it in a gel water bath with a temperature of 5 degrees to solidify. After curing, the film material was peeled off from the glass plate, and the film thickness was about 140 microns. The membrane material was thoroughly washed with deionized water, and then dried at room temperature. Structural observation shows that the membrane material is composed of a dense skin layer and a microporous support layer, which is a typical asymmetric structure.

[0050] With reference to the characterization method in Example 1, the thickness between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com