Forward osmosis composite membrane and preparation method and application thereof

A composite membrane and forward osmosis technology, which is applied in the field of membrane separation, can solve the problems of not slowing down the internal concentration polarization in the forward osmosis process, and achieve low mass transfer resistance and reduce the effect of internal concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of graphene oxide-based polyamide composite membrane:

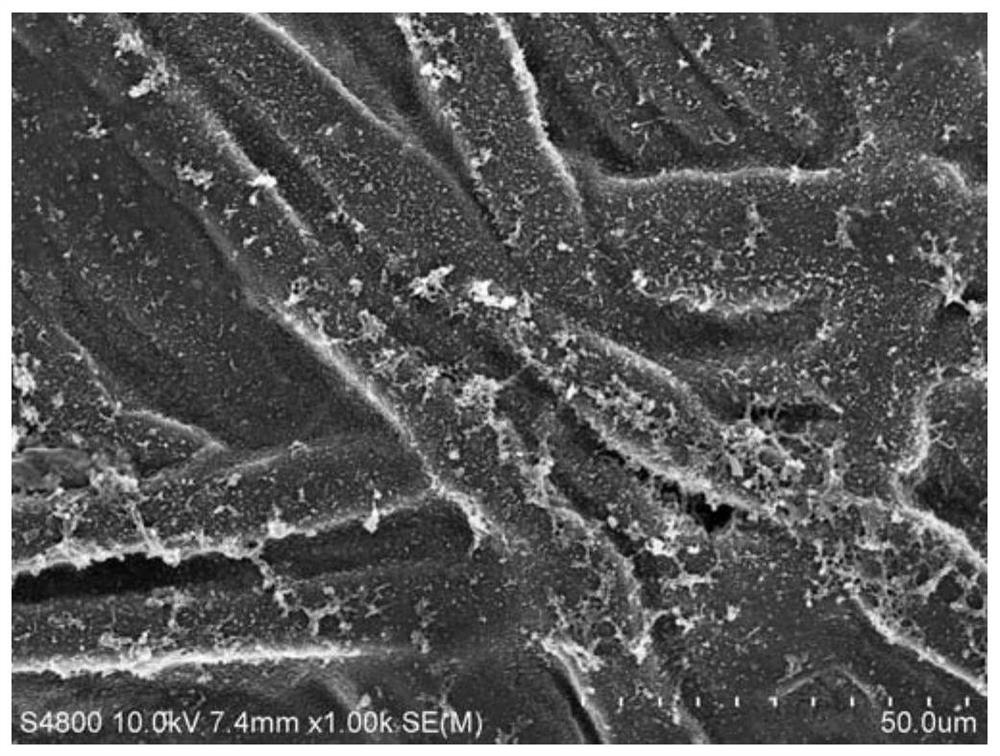

[0036] 1) A polyethersulfone (PES) microfiltration membrane with an average pore size of 0.8 μm was used as a macroporous substrate, and pretreated with 2 g / L dopamine hydrochloride and a Tris buffer solution with pH=8.5 for 10 h.

[0037] 2) In order to obtain a graphene oxide (GO) modified membrane, 30ml of GO solution with a size of 20μm and a concentration of 0.004mg / ml was deposited on the surface of the above-mentioned pretreated PES membrane by vacuum filtration under a pressure of 0.01MPa .

[0038]3) With the PES film of the above-mentioned deposited graphene oxide (GO) layer as a support layer, an interfacial polymerization method is used to form a polyamide separation layer on the graphene oxide (GO) layer to obtain a composite film (that is, graphene oxide in the composite film (GO) layer as an intermediate layer): first, the support layer is soaked in an aqueous solution containing 2wt% m-...

Embodiment 2

[0045] Preparation of graphene oxide-based polyamide composite membrane:

[0046] 1) A polyethersulfone (PES) microfiltration membrane with an average pore size of 0.8 μm was used as a macroporous substrate, and pretreated with 2 g / L dopamine hydrochloride and a Tris buffer solution with pH=8.5 for 10 h.

[0047] 2) In order to obtain a graphene oxide (GO) modified membrane, 30ml of GO solution with a size of 20μm and a concentration of 0.0025mg / ml was deposited on the surface of the pretreated PES membrane by vacuum filtration under a pressure of 0.01MPa .

[0048] 3) With the PES film of the above-mentioned deposited graphene oxide (GO) layer as a support layer, an interfacial polymerization method is used to form a polyamide separation layer on the graphene oxide (GO) layer to obtain a composite film (that is, graphene oxide in the composite film (GO) layer as the middle layer): First, soak the supporting layer in 2wt% m-phenylenediamine aqueous solution for 2 minutes, pou...

Embodiment 3

[0057] Preparation of graphene oxide-based polyamide composite membrane:

[0058] 1) A polyethersulfone (PES) microfiltration membrane with an average pore size of 0.8 μm was used as a macroporous substrate, and pretreated with 2 g / L dopamine hydrochloride and a Tris buffer solution with pH=8.5 for 10 h.

[0059] 2) In order to obtain a graphene oxide (GO) modified membrane, 30ml of GO solution with a size of 20μm and a concentration of 0.0025mg / ml was deposited on the surface of the pretreated PES membrane by vacuum filtration under a pressure of 0.01MPa .

[0060] 3) With the PES film of the above-mentioned deposited graphene oxide (GO) layer as a support layer, an interfacial polymerization method is used to form a polyamide separation layer on the graphene oxide (GO) layer to obtain a composite film (that is, graphene oxide in the composite film (GO) layer as the middle layer): First, soak the supporting layer in 2wt% m-phenylenediamine aqueous solution for 2 minutes, pou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com