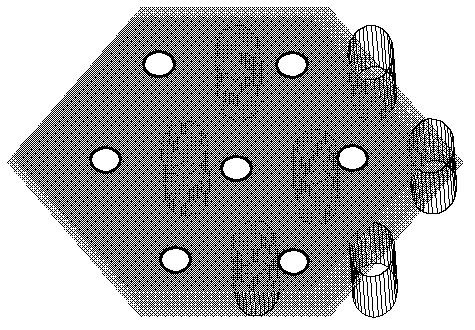

Porous graphene with stratified columnar support structure and its preparation method

A porous graphene and support structure technology, applied in the field of material science, can solve the problems of insufficient utilization of specific surface area and easy agglomeration, and achieve the effects of easy industrial production, high specific surface area and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

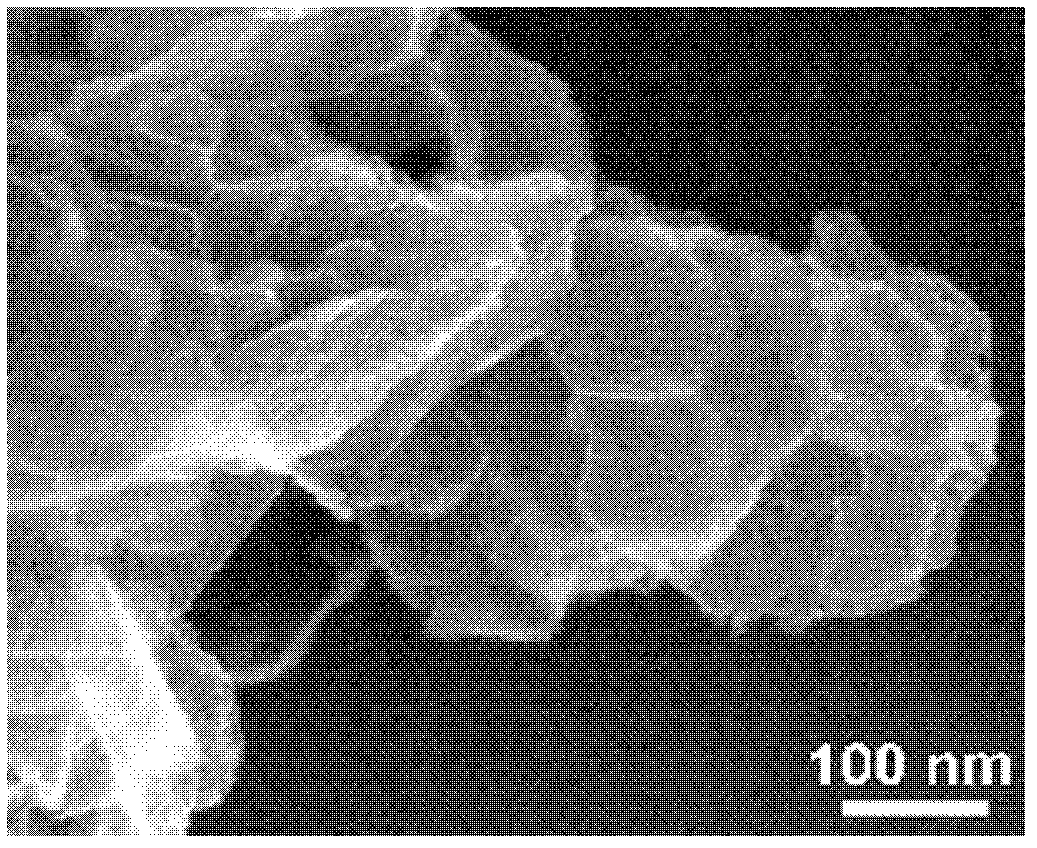

Embodiment 1

[0022] The lamellar porous MgO with a thickness of 2nm and a pore diameter of 2nm was uniformly mixed with polyethylene and toluene at a weight ratio of 1:10:100, vacuumed to remove the solvent, and then placed in an inert atmosphere of nitrogen for heat treatment at 600°C for 300min. After cooling , collect the solid, place it in dilute hydrochloric acid and wash it fully, filter it and wash it with water until it becomes neutral, and dry it to obtain the interlayer columnar porous graphene material.

Embodiment 2

[0024] The lamellar porous MgO with a thickness of 10nm and a pore diameter of 5nm was uniformly mixed with pitch and tetrahydrofuran at a weight ratio of 1:5:50, vacuumed to remove the solvent, and then placed in an inert atmosphere of nitrogen for heat treatment at 700°C for 200min. After cooling, The solid was collected, washed fully in dilute hydrochloric acid, filtered and washed until neutral, and dried to obtain a porous graphene material with interlayer columnar shape.

Embodiment 3

[0026] The layered porous MgO with a thickness of 4nm and a pore diameter of 2nm was uniformly mixed with glucose and N,N-2 methylformamide at a weight ratio of 1:20:500, vacuumed to remove the solvent, and then placed in an inert atmosphere of nitrogen Heat treatment at 800°C for 60 minutes, after cooling, collect the solid, wash fully in dilute hydrochloric acid, filter and wash until neutral, and dry to obtain the interlayer columnar porous graphene material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com