Making technology for polymer lithium battery pole slice

A preparation process, lithium battery technology, applied in the direction of electrode manufacturing, battery electrodes, electrode carriers/collectors, etc., can solve the problems of increased production intensity, reduced production intensity, and reduced production efficiency, so as to improve production efficiency and reduce production processes , Excellent effect of rate discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

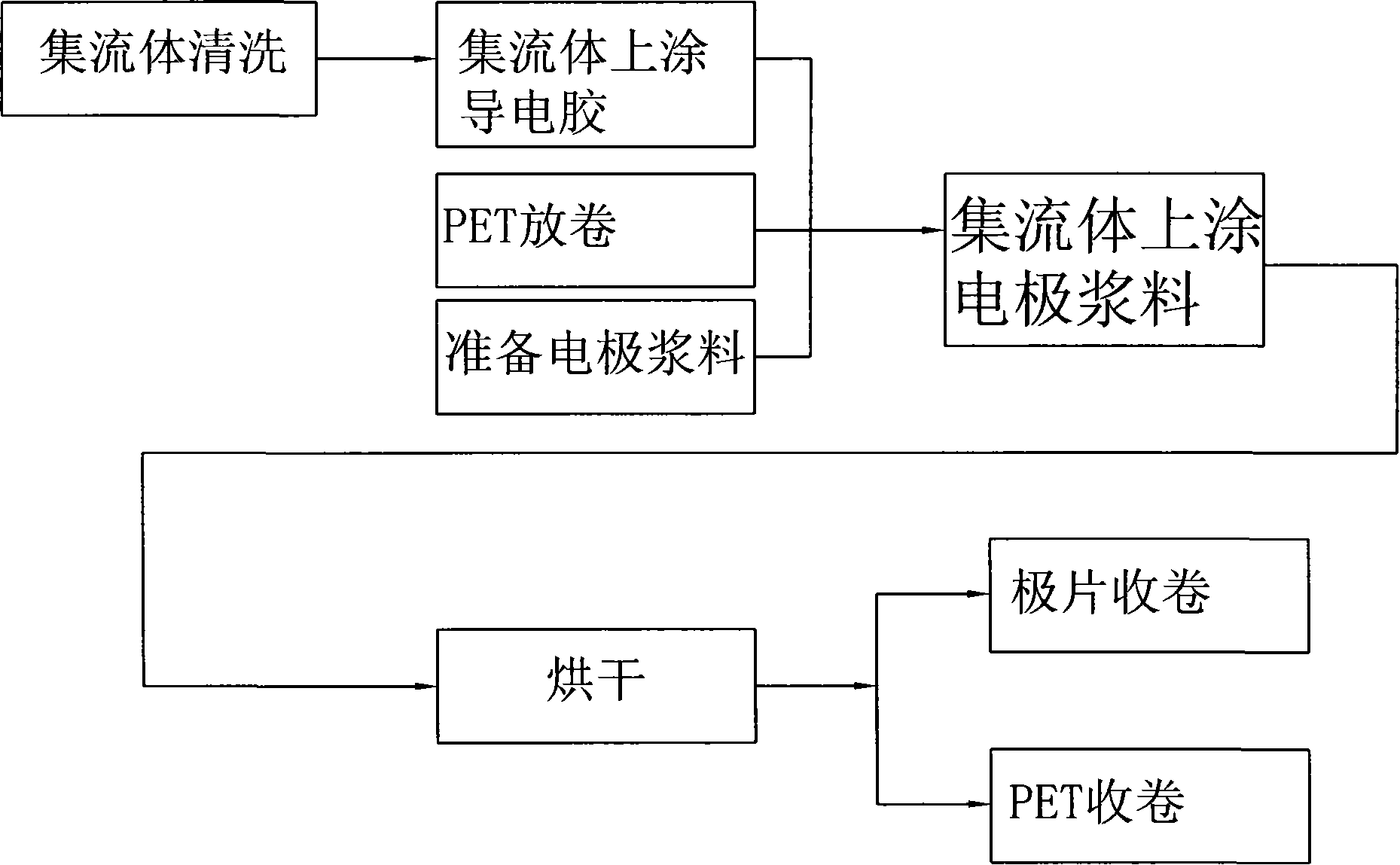

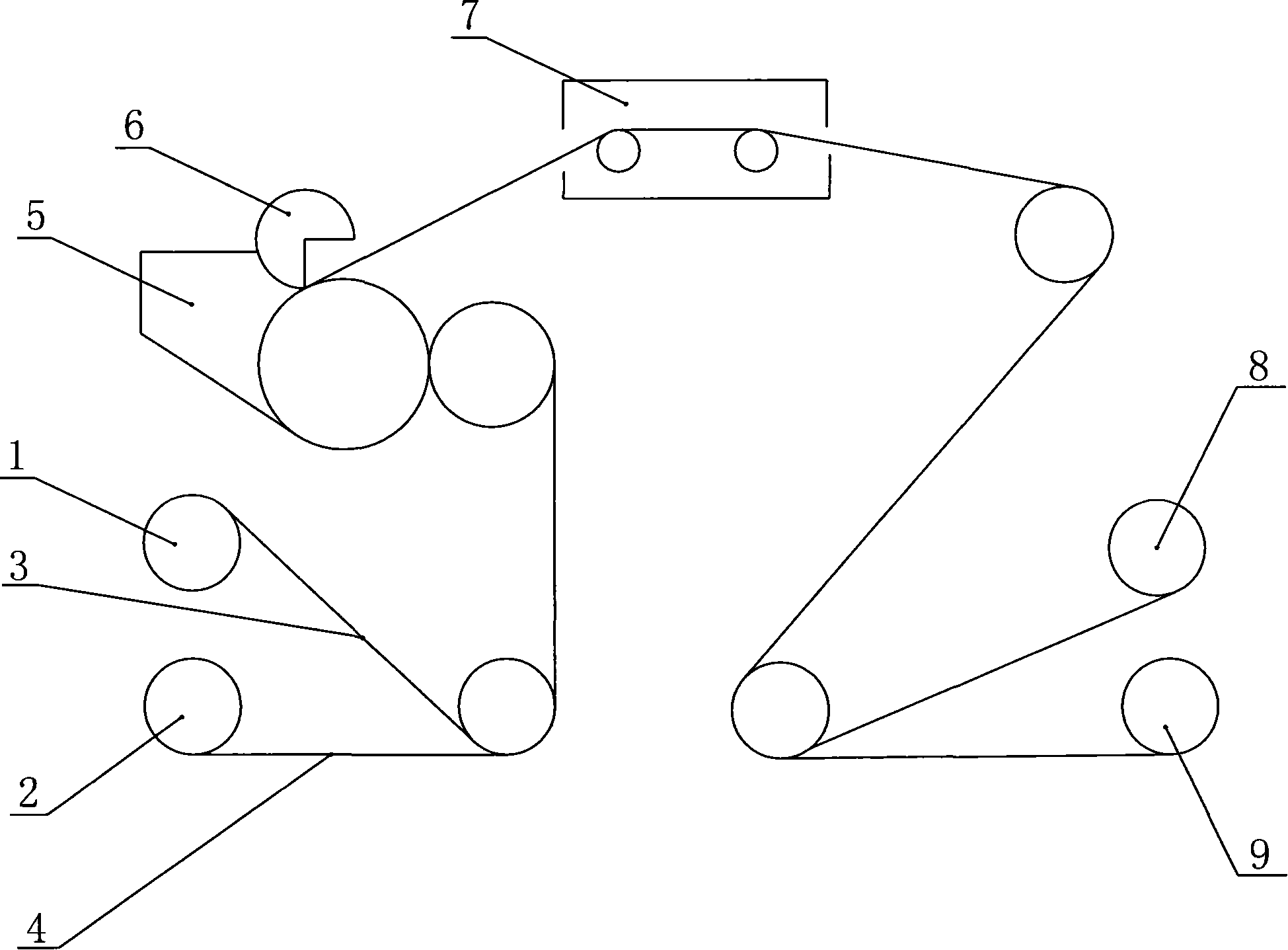

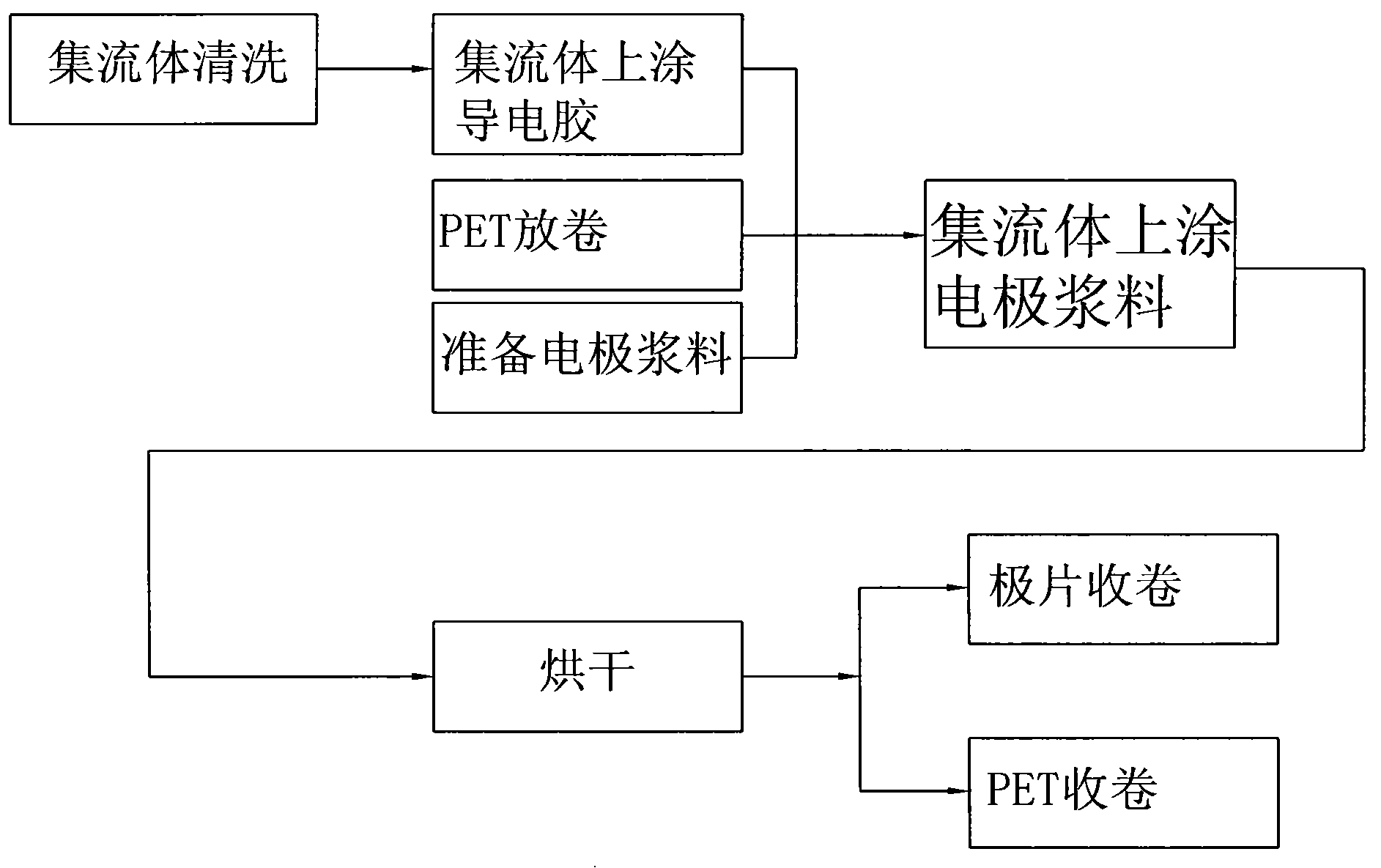

[0027] Embodiment 1: A kind of polymer lithium battery pole piece preparation process (see attached figure 1 attached figure 2 ), using PET4 as a carrier during production, including the following steps:

[0028] a. Cleaning: Select a copper foil with a porosity of 40% and a pore diameter of 1.2 mm as the current collector 3, reserve 20 mm on both sides of the copper foil, first remove oil from the copper foil, and then clean it with an active agent. The active agent is controlled at right The water mass ratio is 1 / 9, at a temperature of 40°C, wash for 70s, then pickle, the concentration of pickling is controlled at 0.3mol / L, and at a temperature of 35°C, wash for 70s, then rinse with water and remove Dry at a temperature of 80°C;

[0029] b. Coating conductive glue: apply a layer of conductive glue on the dried current collector, the thickness of the conductive glue is 8μm, and then fully dry;

[0030] c. Unwinding: place the current collector on the current collector unw...

Embodiment 2

[0034] Embodiment 2: a kind of polymer lithium battery pole piece preparation technology (see attached figure 1 attached figure 2 ), using PET4 as a carrier during production, including the following steps:

[0035] a. Cleaning: Select an aluminum foil with a porosity of 60% and a pore diameter of 1.5mm as the current collector 3, reserve 20mm on both sides of the aluminum foil, first remove the oil from the aluminum foil, and then clean it with an active agent. The active agent is controlled at a mass ratio of water 1 / 10, at 45°C, wash for 90s, then carry out alkali washing, the concentration of alkali washing is controlled at 0.8mol / L, at 45°C, wash for 50s, then rinse with clean water and dry at 100°C Dry at a temperature;

[0036] b. Coating conductive adhesive: apply a layer of conductive adhesive on the dried current collector, the thickness of the conductive adhesive is 10 μm, and then fully dry;

[0037] c. Unwinding: place the current collector on the current coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com