Leakage-proof tyre and preparation method thereof

A technology for preventing air leakage and tires, which is applied to tire parts, transportation and packaging, and vehicle components, etc. It can solve problems that affect driving safety, tires lose dynamic and static balance, etc., so as to improve driving safety and reduce tire maintenance costs , Solve the effect of tire micro-leakage and nailing air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The typical specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

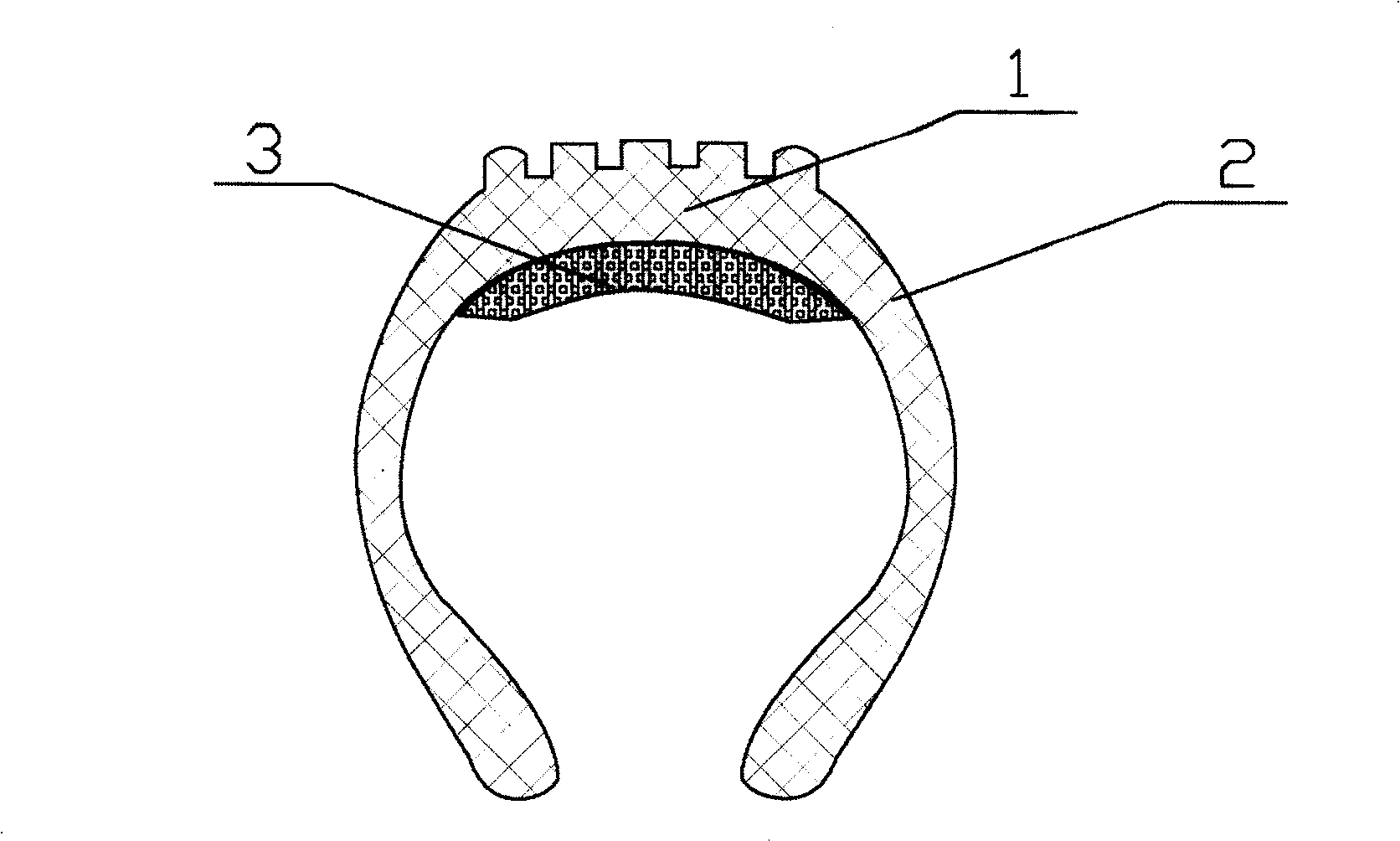

[0020] Refer to attached figure 1 , 2 , The air-run-proof tire of the present invention comprises a tire tread 1, a tire shoulder 2, and an inner coating layer 3 of the tire. The inner coating layer is a coating layer of elastomer material with self-sealing performance, which is a blend of vulcanized rubber, thermoplastic elastomer and resin. This example is a blend of natural rubber / butyl rubber blend, softening oil and block copolymer with polystyrene as hard segment and olefin copolymer as soft segment.

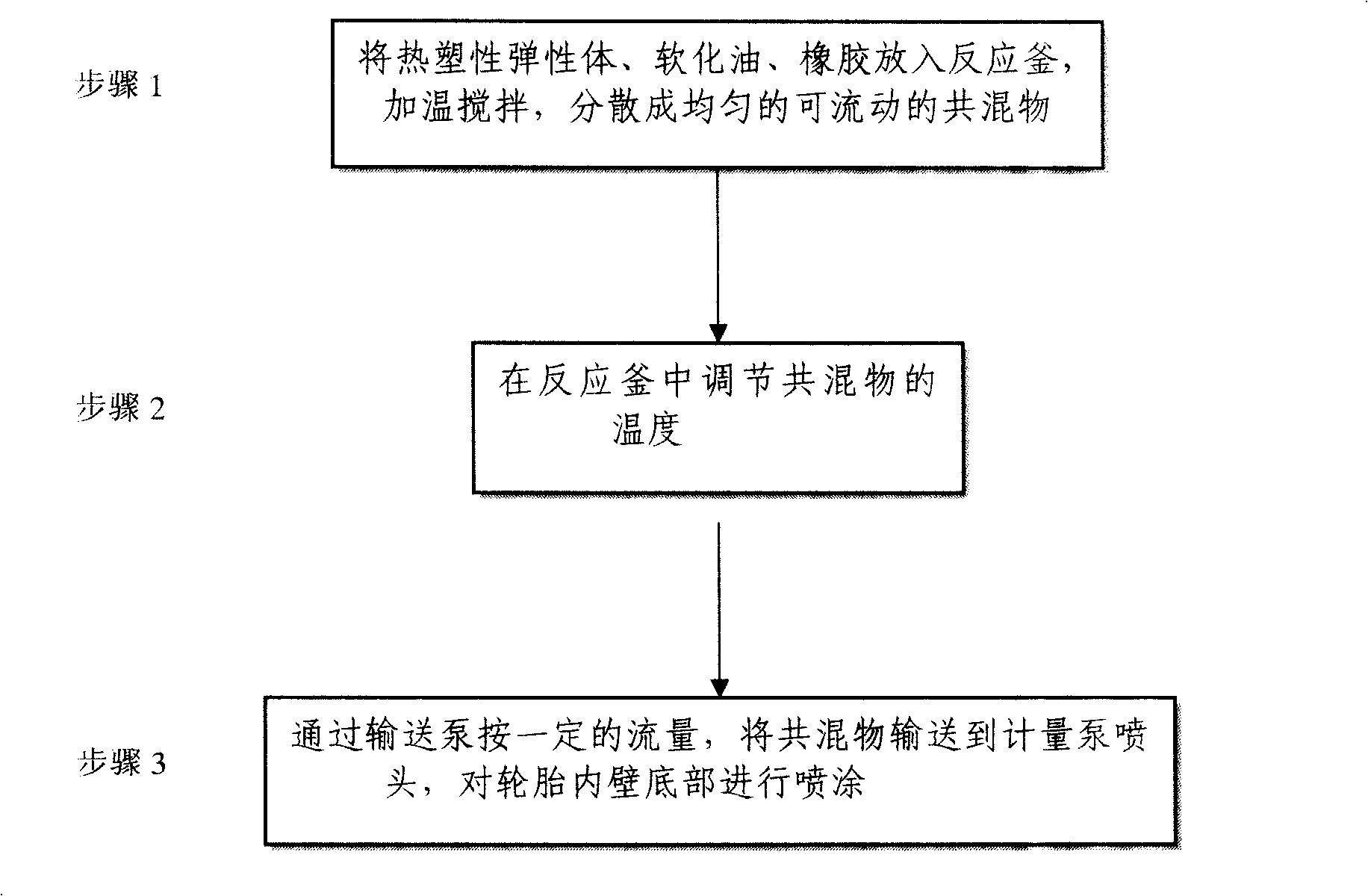

[0021] Refer to attached image 3 , the manufacture method of air-run-proof tire of the present invention is as follows:

[0022] Step 1, putting thermoplastic elastomer, softening oil, vulca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com