Plastic liner fiber fully-wound gas bottle mouth structure

A technology for wrapping gas cylinders and inner liner, applied in fixed-capacity gas storage tanks, installation devices for container construction, gas/liquid distribution and storage, etc., can solve safety hazards, hydrogen leakage, and large differences in modulus and thermal expansion rate and other problems, to achieve the effect of self-sealing, reliable connection and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

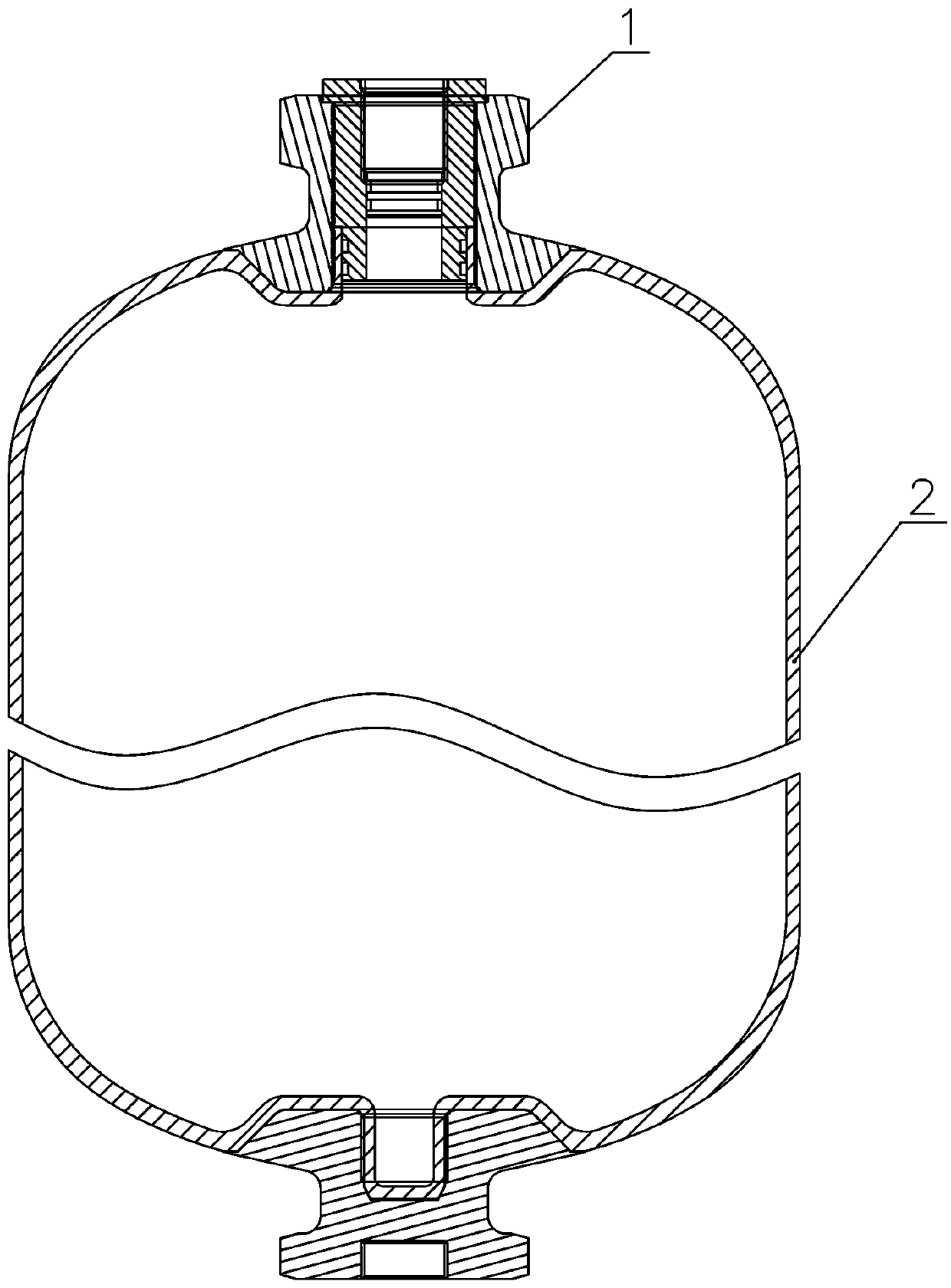

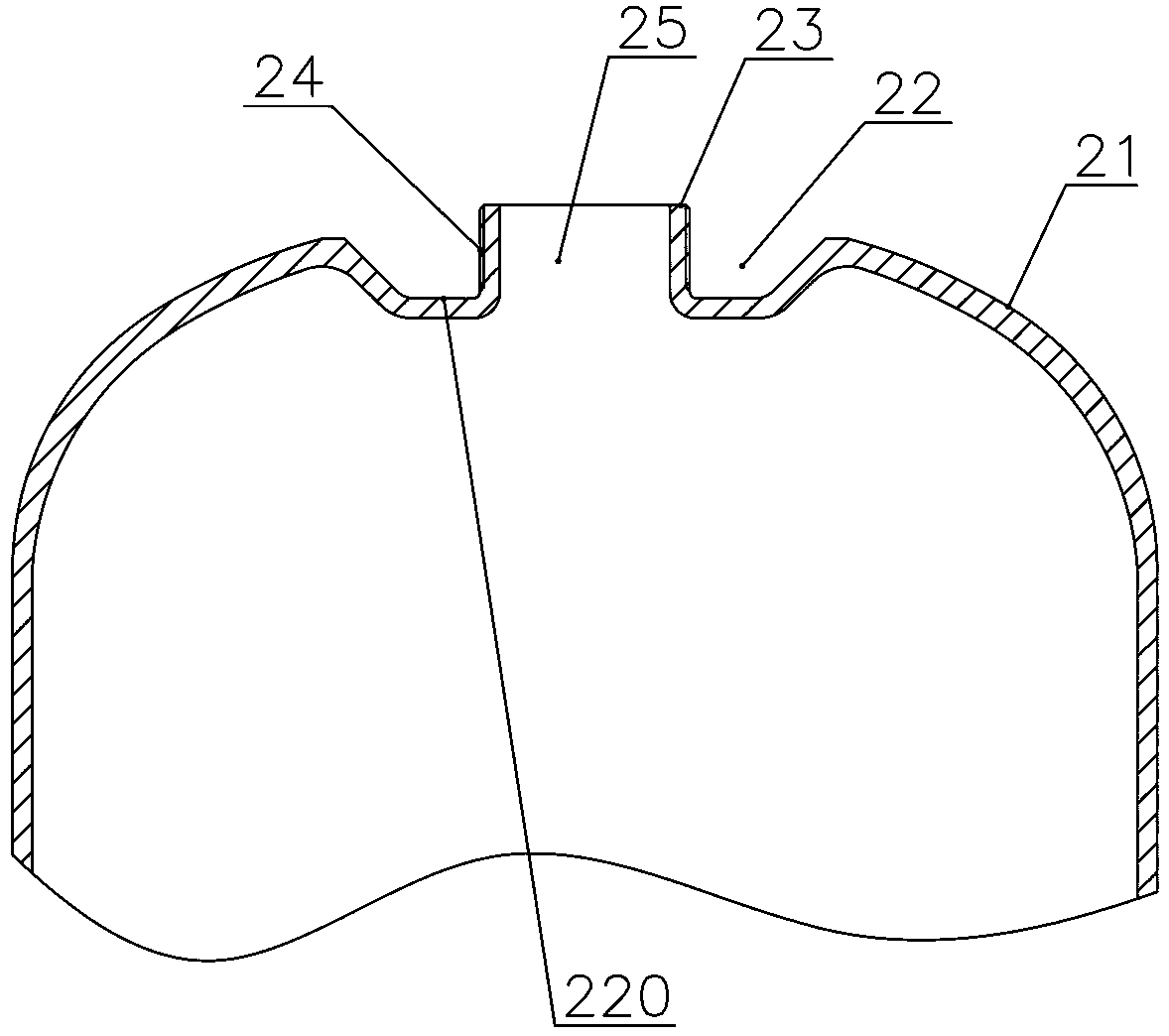

[0023] Such as figure 1 and figure 2 As shown, the mouth structure of a plastic liner fiber fully wound gas cylinder described in this embodiment includes: a metal bottle mouth 1 and a plastic liner 2, and the top of the upper head 21 of the plastic liner 2 is recessed inward to form Embedding groove 22, in the middle of the embedding groove 22, a connecting pipe 23 protruding outwards and coaxial with the plastic liner 2 is provided. The head 21 is integrally formed, and a first external connecting thread segment 24 is arranged on the outer pipe wall of the connecting pipe 23 . In this embodiment, the plastic liner 2, the upper head 21, the lower head, and the connecting pipe 23 are integrally formed by nylon blow molding.

[0024] Such as figure 2 As shown, the groove bottom of the embedding groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com